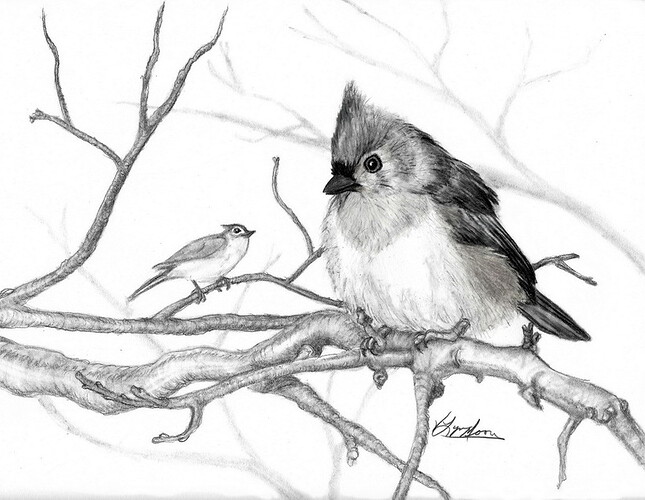

Designing for a detailed engrave is going to be interesting, sometimes challenging. The Glowforge part (SW and H/W) is easy using Proofgrade but when working with a laser I will need to be very aware of subtle differences in greyscale. To get the light shades the darker parts might end up too dark. I have some fairly good image editing S/W that I can adjust the dark and light separately, might try it later. But still, I just grabbed one of the wife’s random pencil drawings, threw in Proofgrade maple plywood, and left all settings automatic. (340 lines/inch, ~3 1/2" square) A work in progress.

Original drawing