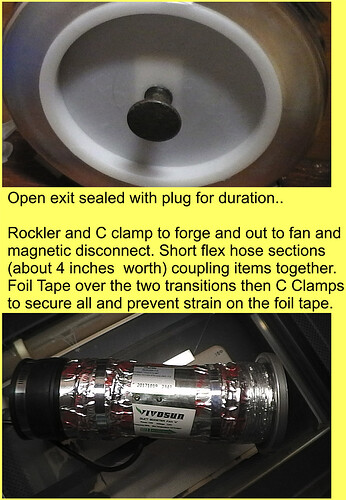

The foil tape is a buffer to transition leaks. That said → you would not want it on the glowforge exhaust ring to tube section because it is not easily removed.

I have a bit of overkill going on, since I have less than 2 feet to work with and one would think that is a straight shot out the hole.

But, I want to be able to block the exit when not in use (hot and humid), and also be able to remove the tube from the machine for easy cleaning. Additionally, I had such a terrible resin infused waste build up on my grate once that I felt a booster fan was needed to get that sort of waste further towards the exit before it slows down and starts sticking around.

So Magnetic Disconnect to Booster Fan to Easy Disconnect, all in less than 2 feet.

Where the foil tape comes in is over the short flex tube sections used for coupling the 3 items together. Once secured and permanent, it forms another leak barrier to whatever you used to secure the transitions (band clamps for mine).

https://www.amazon.com/gp/product/B01C82SYZ0/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1

https://www.amazon.com/Rockler-Dust-Right-Ports-2-Pack/dp/B0025AC6MI/ref=sr_1_6?s=hi&ie=UTF8&qid=1515005988&sr=1-6&keywords=rockler+dust

2 clamps come in Rockler Clamp order.

And my rig in all it’s glory (no one can see it unless I am cleaning it so pretty was not an option)…