Oh, right. But, Well… you might be able to, maybe with engraving or with a little jig.

Very easy to do with any table saw, handheld circular saw, router, or even a handsaw and a miter-box.

Depending on the size, you can also fake a french cleat by using 45*-angle cut trim, and pegging it. The gf should be able to make perfect, aligned peg-holes!

Duh. Now I think about it you should be able to just tip up a piece at 45 and zap it (although you might run into thickness constraints.) Because a cleat need not be integral.

Now I am think about making a hinged thingy that would let me set arbitrary angles for stuff to be lasered, within the height restrictions. It would be cool to be able to do, say, a sliding dovetail.

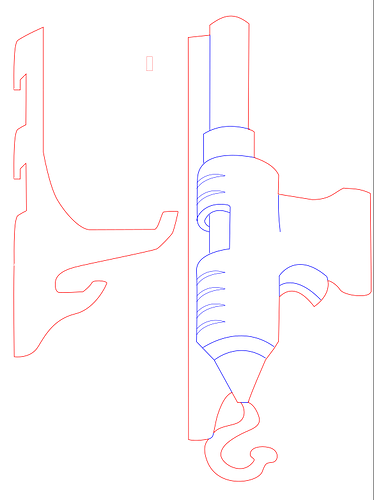

I think a fake-out, pixelated french cleat is pretty much what I was going for… Would it be better to have the slant? Can’t I just tetris together blocky shapes instead of sloping things?

There are probably reasons.

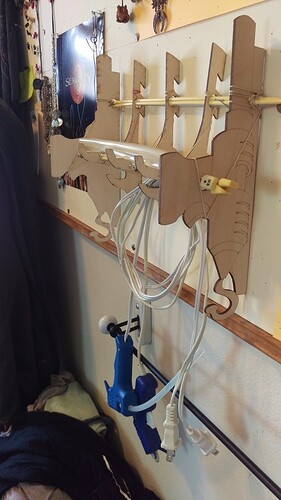

Woooo, progress! Two of three dimensions are just about set! Now to tackle the horizontal axis… I was thinking laser cut slats, but now I’m pondering dowels… Break out of having every part of the thing come off the laser bed… And it could be super simple to, like, thread all the pieces on a number of dowels… Yeah, I think that might win.

If it isn’t just because the slant is easier and quicker with traditional tools, then maybe strength or ease of insertion/removal/alignment, but that’s a full-blown guess.

I’m no cabinet-maker, but as long as the wood is thick enough I would think your french-tetris cleat would hold just fine.

I mean, you could find that the wood is too thin and have to adjust, or that the thin parts are too tight to easily fit together and pull apart, or that there is not enough wiggle room to pull it up off the mounting point… a lot of that will depend on the mounting point too (the wall-mounted side of the french cleat), and how often you want to be able to take it back apart

Yeah, the whole point of the french version is that it’s self-assembling once you get the two edges past each other, and it comes off easily. If you do a pixelated version, you still have to fit the bits together precisely. And if there’s even a little nonuniformity in thickness, Murphy says it will never fit, unless you deliberately allow for a gap.

I still have a bunch of tablesawn cleat stock hanging around somewhere…

The other advantage of the slanted french cleat is that as it is pulled down by gravity, it is getting pushed harder and harder against the wall, whereas a tetris block version would not give you that horizontal force vector.

Can I say again (and probably again later), how much I appreciate you all? Thanks so much for workshopping with me.

I think I’m sold on the french cleat. I’m going spelunking through the wood shop tools. I bet we can do a wedge cut.

What have you got, because pretty much anything can do the necessary angled cut. I made mine on a table saw, but a circ or a saber saw would do fine (or a scroll or bandsaw if you have a good touch). Or a handsaw if you’re patient. Lay the cut out through the middle of a strip of wood and get twice the length for one cut. (There are even miter bits on a router or shaper that could do it, but that would be excessive.)

I know we have a table saw and a miter saw… I’ve not tried anything but straight cuts with either and I broke one miter in a way that flat terrified me already, so I’ll probably try pivoting the table saw…

I do not have the patience for the handsaw.

Nor I. The crucial thing for doing this on tablesaw (or miter saw) is to get the setup right. You need lots of featherboarding/guides to keep the wood in place as you saw, and (IIRC) you must arrange the rip fence so the the tilted blade tilts away from the fence (otherwise the cut board can get trapped between the fence and the blade and Bad Things can happen).

Or, if you only need a short piece of cleat, you could cut it off the end of a big piece rather than trying to rip a narrow-ish strip in half…

Meanwhile, in franken-project land…

I sweartogawd I measured the dowels we have at the lab. I even used the digital calliper like our 3D expert taught me. I figured kerf could only give me extra room… But no. They wouldn’t go in.

Which is a ranty way of asking that you forgive the knitting needles.

I feel like I either need to build in more depth for the reservoir section, or throw that idea out and just make the whole thing a bit extra swoopy for holding a big pile of sticks…

The gun-cooling/holding hooks make me super happy.

Also, see?? I made the french cleats straight. Because you guys teach me valuable things. You rock. <3

(Now I should go think more about a one-sheet project…)