I’m trying to make an arch-topped picture frame, shallower at the top, so that the glass slopes down.

It’s in two parts - a lid like a standard frame, and a shallow back, with the top edge, supporting the glass, lower at the top than the bottom.

Lid done, so it’s the back that’s the problem

It’s to be made using thin(2mm) plywood, cut on the laser.

I’m using Inkscape to generate the graphic, but my problem is one of geometry/node manipulation.

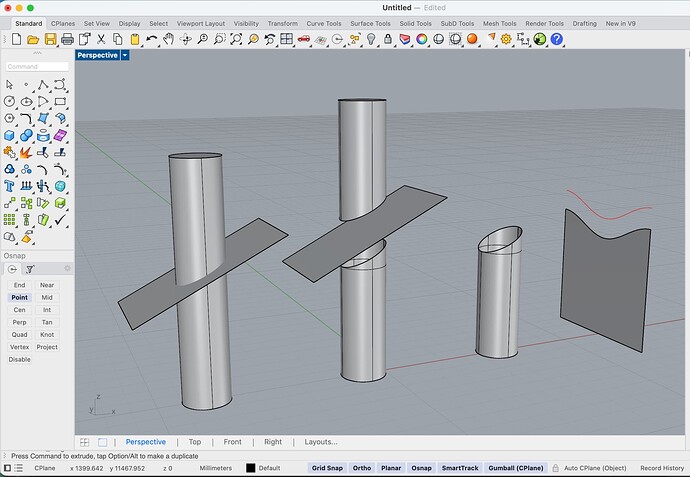

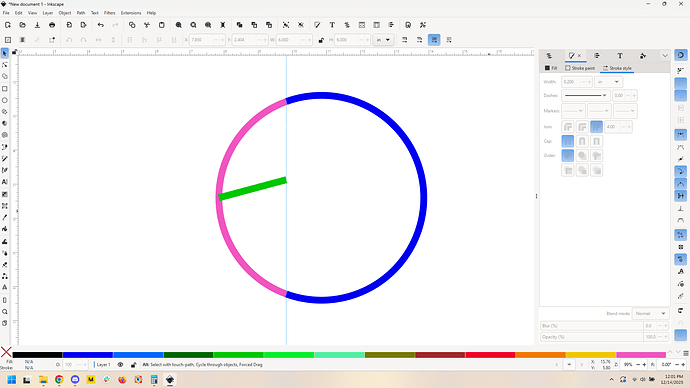

Think of a short cylinder.

Now make a slice through the cylinder, half-way down, and at a shallow angle to the horizontal.

Then make a pie-shaped slice down through the center of the cylinder, at 140 degrees,

and it’s the red surface in the drawing that I am trying to draw.

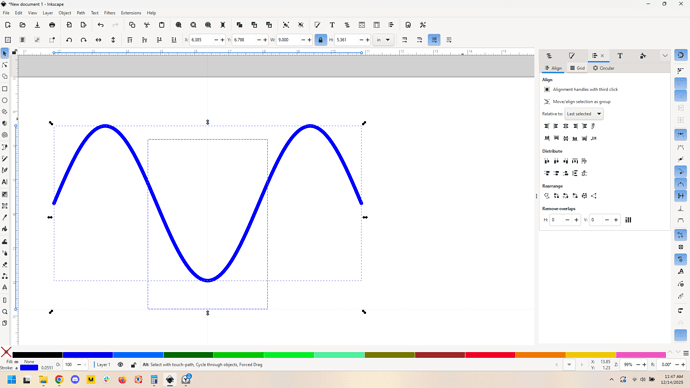

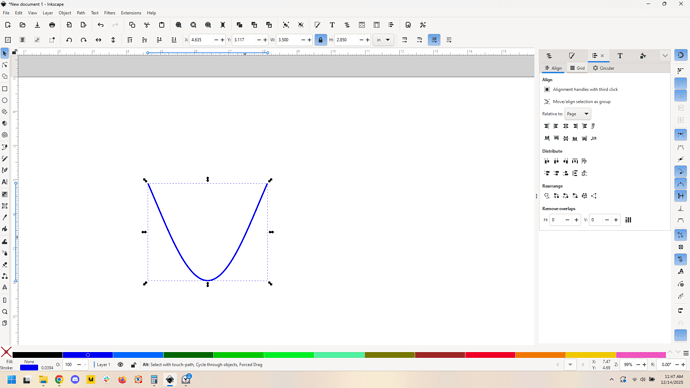

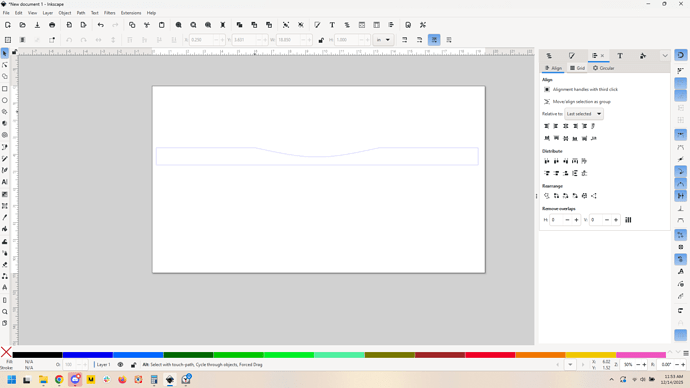

If I start with a long rectangle in Inkscape, convert it to a path, then pull the center of the top edge downwards, the resulting shape, when wrapped around a circular former, does not produce a top edge that is a flat plane.

I’ve tried using the node control tools, but can’t achieve an accurate result.

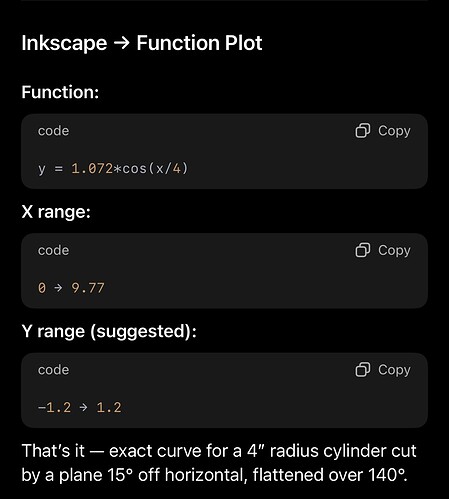

I’m sure there must be a mathematical representation of the shape, and/or a way of achieving it in Inkscape.

Any suggestions welcome.