Hmm, I thought the pro was supposed to be able to work continuously. 90 minutes to recover from 38 minutes use is a pretty low duty cycle (30%) for a professional laser. I wonder what temperature the room has to be for continuous use.

Great write up and really nice setup you have for your Glowforge. Thanks for sharing!

Woo hoo!

I’m delighted you’re off and printing!

I’m puzzled by this. I don’t believe you should be able to see a cooling message without an active print. Can you share a bit more detail (in an email or Problems & Support post would be great)?

Think the confusion Is because he said the cool down warning was received after the print ended. Didn’t say it was received when trying to start the next print.

I will file a report when I get back into the shop in a few hours, but @rpegg has it right, I was planning on running an engraved version of the sunstone on the flip side of the scored version, and had the file waiting, but my Print button had turned into a Cooling Down button.

I bumped the A/C down by 2 degrees, it hasn’t happened again. Longest print since then was about 2.25 hours, and I ran a 20 minute print immediately after that.

Here is the Dark-engraved version of the sunstone:

So 30% duty at 79F but 100% at 77F?

That is a surprising difference for only 2F, or was it 2C?

Degrees Fahrenheit.

That’s always impressive to see.

It’s quite possible that the measured temperature is accurate. But everything is anecdotal until it isn’t. Have a half dozen digital temp sensor and IR temp sensors. There is a wild difference +/- 6 degrees F between them even though they all proffess similar accuracy. And up to 12 degrees F between what my digital AC control says and the Glowforge air intake.

Is the operating temp for the GF too narrow for some people? Sure. But, if I quoted numbers you would be wise to not set them as an exact value.

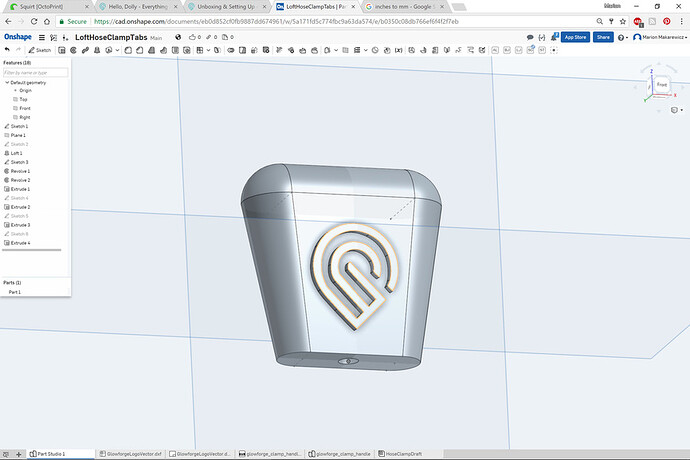

@jbv, quick question. Is it a worm screw hose clamp or the springy rings? I have printed some @palmercr -inspired clamp handles, but am curious as to what is shipping now. The setup pictures show a worm drive and not spring. Thanks. Tried to find a shot of some recent setups, but couldn’t quite make it all out.

Mine shipped with the springy clips, which I tried to use but they are evil and bit me, so I used wormdrive clamps from home depot instead.

Thanks. I’m all set then. I’ll post pics of the clips. Glowforge bug an all! Oh and one more favor, could you give me an exact as in caliper measurement of the thickness of the spring clamp if it isn’t too much trouble. Metric or imperial but 3 digits if imperial.

I’m seeing 0.125"

Thanks. I made them 4 mm, so I’ll print some new ones. I’m sure they’d work, but I’m just wanting to do something tonight!

So cool, everybody will want one! (actually, two)

Actually four! Two clamps, one for window outlet and one for Glowforge outlet.

I certainly hope you bit them back…lol

Ditto my Basic last week.

I have never been a fan of those spring clips - on anything.

Bite me once, shame on you. Bite me twice and I kill for less than that.