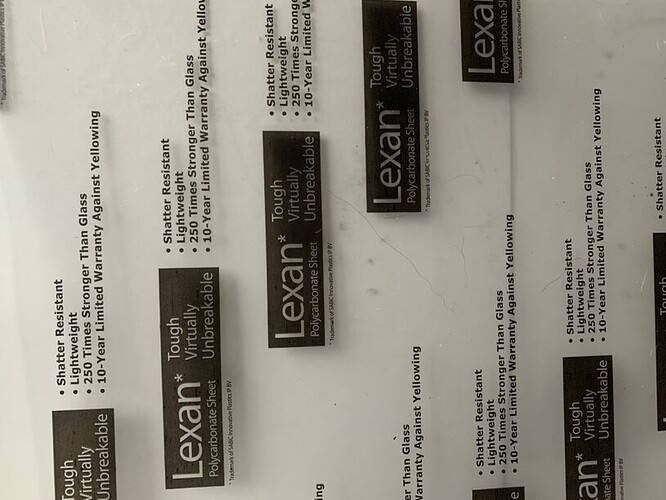

I bought plexiglass from Home Depot to use as I was waiting for my Proofgrade material to come. This is the outcome I got and don’t know why… Please help

Maybe now you know why PG material comes with a paper backing, front and back?

if the back was not protected with some sort of masking , then this is what can happen. Search this forum and you will find all sorts of recommendations about brands to use.

What do you mean the back protected with masking? I’m sorry if that sounds dumb but I’ve only had my machine for a month so really new at this.

Lexan is polycarbonate, and not suitable for use on the Glowforge.

Plexiglas is a brand of acrylic, which is perfect for use on the Glowforge.

Gotcha, is there a list somewhere of what is suggested to use if not using Proofgrade?

Arent you supposed to remove that before cutting? Again sorry if I sound stupid.

The masking is there to protect the material while cutting, you should not be removing the paper masking from your materials beforehand. Helps with cleanup and with materials like acrylic will stop parts of the piece from being damaged from material in the cut depositing onto the surface.

Well that makes a lot of sense, wish I knew that a month ago lol. Thank you.

Is there someplace to find what other materials/brands are safe to use

Lots off info out there on google, but for the most part you want to avoid materials that catch fire easily and never use any material that contains chlorine as one cut with a material like that can turn your machine into a literal paperweight. With all new products i research the material safety data sheets, contact suppliers and run some other tests that can be found online.

In the Tips and Tricks section you will find a link to a Google doc with materials (along with a huge amount of other handy information.)

There are also many resources online, this one from a maker space group in Texas is pretty handy.

As suggested above, you must test the material you have and not just blindly follow what settings worked for others.

Thank you

Thank you so much

When engraving acrylic, not that polycarbonate you have, and sometimes wood products people will remove the masking when engraving raster images. You don’t have to, but it can make cleanup easier. Also, if you are going to be sanding a part after lasing it, you may as well not mask the side(s) you’ll be sanding. Sorry to complicate things, you’ll learn quickly.

A couple other quick notes for you on non-proofgrade acrylic (I’m sure you can find all of this and tons more searching the forum too  )…

)…

- There are 2 general types of acrylic, cast and extruded-for laser use you’ll have an easier time with cast

- Many non proofgrade acrylic will come with a clear or tinted plastic masking (adhesive sheet) on it-you do want to remove this before lasing it

- You can use paper based masking to cover both sides before lasing-this is used much more on wood, but it can also be useful for acrylic-the paper protects the material from smoke stains on the front and flashback burns on the back (there are lots of forum topics discussing types of masking and online sources)

- You can clean smoke stains off many materials with isopropyl alcohol, but don’t do this with acrylic-it can cause crazing/cracking

- Acrylic is flammable…you should never leave the GF unattending while cutting, but be a little extra vigilant with acrylic.

And some good online sources for acrylic include Johnson Plastics Plus, EStreet Plastics, BF Plastics

Although not GF sourced, this link is very informative for Safe & Unsafe Materials for the Laser Cutter.

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.