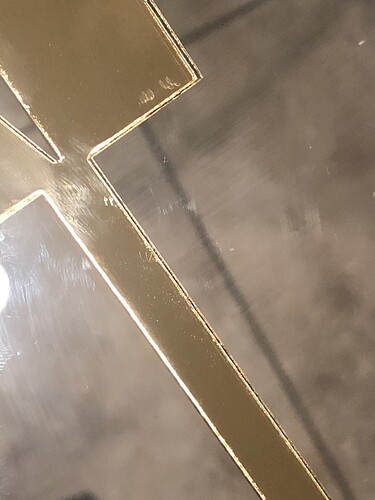

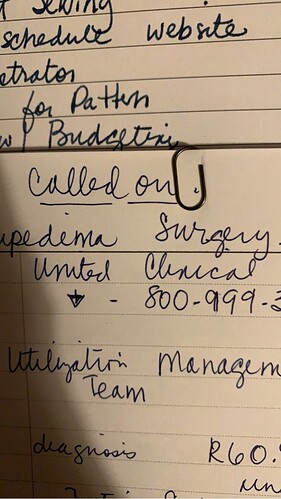

Ok, so I have hit a snag with gold mirrored acrylic (purchased from Canal Plastics) and I was hoping a Glowforge user way more skilled than myself might take a look at these pictures and let me know what I might be doing wrong. Settings currently used are 150 speed and 100 Power (but only cuts through block letters and leaves script cut only halfway through the mirrored acryclic) or 150 speed and full power (as was used to cut the attached image) but lots of impurities. Thank you in advance for any insight!

Hard to see the problem in the pics. Probably much more noticeable in person.

I’d say a couple of things…

- If this stuff is masked, try removing the masking before cutting. Some masking isn’t meant to be lasered.

- If this stuff isn’t masked, try masking it. Both sides. Masking can reduce smoke and flashback danage.

- Make sure you measured the thickness w/ calipers and entered it in your settings.

Lemme know!

Thank you Tom! Yes I do remove the plastic on top and then mask the mirrored side. I am just wishing I could get somewhere between the 100 and full power range because it feels like a middle point would fix everything.

I haven’t cut gold mirror, but I’ve cut a lot of mirror and I just use the PG settings and I haven’t had those problems. It looks like those are (for medium) 157 speed and full power - so they’re going faster than you are. Might be worth a shot!

Acrylic is pretty standardized…

That’s where small speed adjustments come into play.

Thank you - I will try that!

can you adjust the power after 100? I thought it was adjustable up to 100 and then the next increment after 100 was just full power while speed remained adjustable

That’s why I said speed adjustments, not power. Slower on 100 power or faster on full power will put you somewhere in the middle. Then you have to determine which option works best for your material.

I’m so sorry - I read the message too fast. Ok will do and thank you!

your edges look like they are getting too hot, are you able to increase the speed a bit and still cut through? How thick is this acrylic? and have you tried cutting it with the clear side down it might help but im not 100% sure on that.

The mirrored acrylic is 1/8 inch and I always cut it masked with the special paper (not plastic) and mirror side down…

you could try flipping it over…

I find that a speed of 140 and 85 power generally works well for me and I mask the backside (non-mirror) and place it so the mirror side faces up on the tray. It can also help to put a thin piece of cardboard or chipboard under it if it keeps giving you trouble.

Did you measure with calipers? Reason being, most companies tend to round off when really that’s not quite what it is. And it can make a difference.

Same as @deirdrebeth, I’ve cut mirrored acrylic myself (not gold either). Almost positive I used the Proofgrade settings and had no issue cutting.

Also totally agree with @deirdrebeth that, generally speaking, acrylic is acrylic. If you find a setting that works well at a particular thickness, you can presume it will work with any acrylic of that same thickness.

I have the rose gold mired acrylic from canal street plastics. I left the plastic on and engraved using PG setting and it came out perfect.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.