Agree with the others, you are doing fine because bamboo is TOUGH material, the fact they use it for cutting boards is testament to that for sure!

Bamboo is a bear for sure. I am sure that there will always be a need for experimentation due to the fact that bamboo boards are a laminated product and the resins used to glue together can be so varied.

I too have written down your settings to try.

My assumption with settings is that there is no one true combination: there are multiple solution sets that will work for a particular material.

Speed 1000? … Am I missing something?

Nevermind… score and engrave…

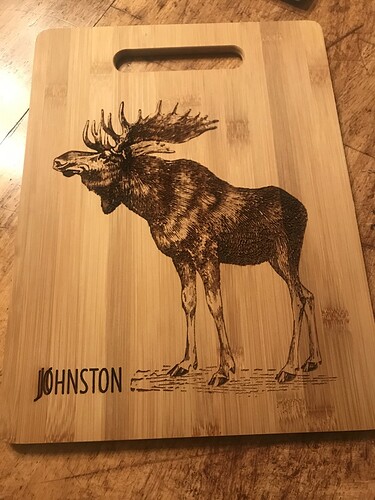

Thanks for the tips! I made this for a Christmas gift. I messed up the name, so it took a little southern engineering with a copper etched inlay to cover up the mistake. I’m pleased. Still learning all the lasering things!

Great Job! Can you provide the setting you used for this design? Also how long did it take to complete one board?

Thanks! Here are the notes I jotted down for this piece: Board was .4" thick. Used thick maple plywood settings at 1000 / 100 / 340, .313 thick maple walnut. 55+ mins to engrave… The photo is before I cleaned it up. It did get a little lighter after washing.

Thanks for those settings… I just finished this! I did wash and oil mine before taking the photo so its faded a little.

Looks beautiful. Love the design!

Lovely result.

Thanks!! It’s based on one of my pen and ink illustrations

I do a lot of Bamboo cutting boards. Speed 1000, Power 90, LPI 340, 1 pass. I never mask bamboo-once it’s done I just use some dish soap and a soft toothbrush to clean it. Comes out perfectly.

How thick are your cutting boards?

I have 2 different sizes I use. .33 and .48 it works for both perfectly.

What settings did you use on the copper? I do a lot of patinaed copper veneers and I was wondering about using the GF to etch it.

Don’t think so. Copper is a metal that reflects the laser beam. While you might be able to remove the patina, you run the risk (small though it is) of reflecting the beam back into the head and doing a lot of very expensive damage.

Be careful if you try it.

You will want to exercise caution when trying to engrave copper as it reflects the red laser light and can potentially damage the lens. That being said, the only way to mark most metals is with an agent such as Cermark or Laserbond.

The copper was electro etched in a completely different process and was not achieved with the glowforge. The wood engrave was the laser project.

Thanks all