Howdy everyone!

I just just moved into my new office for my business and I was wondering if there was a way that I could run my Glowforge machine without a window in a quiet manner? My office is located in a corporate building without windows and I have neighbors that are next door to my office. I want to run my machine without disturbing them. I figured that I would buy an air filter, however, I am concerned if it is as quiet as a Cloudln S4 fan? Is it possible for me to use the fan along with the filter to make it a bit quieter? I know the machine can’t be completely silent, but I just don’t want to disturb the other people in my building. Any suggestions? Thanks!

The official Glowforge filter is quite a bit quieter than the Glowforge exhaust that is turned off when using the filter, However keep in mind that cutting some sorts of material can jam up the filter very quickly . MDF and the plywoods containing MDF centers will jam the filters very fast, Oak is nearly as bad. I would also add a washable prefilter that can catch the big pieces.

Thank you! Does acrylic jam the machine just as much? I practically only use acrylic material.

The acrylic has a lot more stink but way less smoke and crud than any wood, so the filter should be doing better than most cases. ![]()

A filter, by nature is a consumable. The activated charcoal in it that absorbs the acrylic smell will saturate, how long it takes depends on how much you use it - and they ain’t cheap.

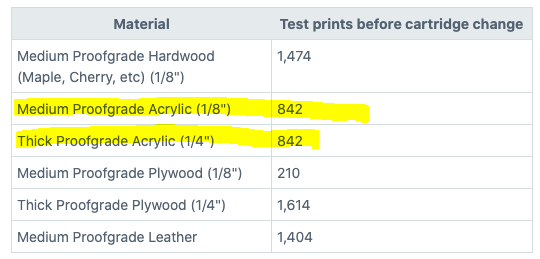

This’ll help

Do they say test prints of what? That could have huge impacts on those numbers.

They have a designated test file that has engraves and cuts. I want to say it runs like 10 minutes or something. I know that doesn’t answer a ton though

It’s meant as a comparison chart though - so it doesn’t matter for that chart. There was no way for them to make a true list of “it’ll last x long” since everyone’s art, and the settings they use have so much variation.

Right but if they based the estimate on doing 10 GOGM or something much much larger, it would make a difference. Still need a point of reference to guess comparatively at ones own usage.

It’s pretty worthless data for that purpose. About the only useful information is the relative life based on different materials. It’s a lot like the pews & zooms. The information density of the data is pretty low.

Thank you for the advice! I feel more confident in purchasing the filter. How was the noise level for you once you got one?

Thank you!

I don’t have a filter, I wouldn’t consider one unless it were for a demonstration like a maker fair. The filter is consumable, and they aren’t cheap.

I use an inline fan booster external to the laser. If you want low noise, the external fan is the way to go. If you have any remaining warranty then you shouldn’t modify the machine at all.

Where would you put the washable prefilter? In the Glowforge itself, or in the vent tube?

The filter goes inside the Glowforge filter unit - not the Glowforge and not the vent tube.

“The test print represents an average Glowforge print; it’s 11 minutes long and is a mix of cutting and engraving that reflects typical usage.”

…is as specific as they get.