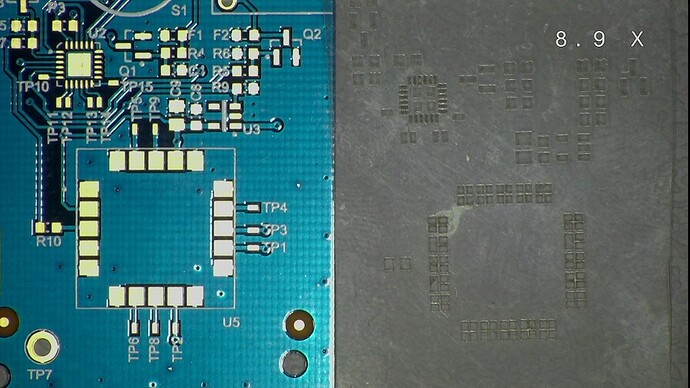

If you make your own surface-mount printed circuit boards, then one thing you’d have to do is send out your Gerber files to have a shop like OSH Stencils create a PCB stencil for you. While these have come down in price a lot in the last couple of years, you still have to wait quite a while to get the stencil back in the mail. But if you have a Glowforge then creating your own PCB stencil is easy!

This quick tutorial will walk you through creating your own PCB stencil. It assumes you’re using Eagle (free version is OK) for your board design. Other CAD tools could be used as long as there is a way to output an SVG file from selected board layers.

For material, you need 2 things:

- 4 mil (0.004") mylar sheets, approximately 8.5 x 11"

- I used this: https://smile.amazon.com/gp/product/B00RDATMOU/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

- 110 lb card stock paper, 8.5 x 11"

- available just about anywhere office supplies are sold. I got mine at Walmart.

We’ll be using Eagle, Inkscape, and the app.glowforge.com web app.

Here’s the process:

- In Eagle:

- In the Layers Tool in BRD view

- Deselect all layers

- Select 20 (Dimension)

- This is for reference only - it will be deleted in Inkscape

- Optionally, you can skip selecting this layer if you don’t need to see the board outline in the SVG file

- Double-click on 31 (tCream) to edit

- Choose the solid pattern (no stippling)

- Pick a color, such as Green

- Select 32 (bCream) instead if you’re making a stencil for the bottom layer

- Select 31 (or 32)

- Layers 20 (optional) and 31 or 32 are the only visible layers at this point

- Still in BRD view, run eagle2svg ULP

- Download from http://eagle.autodesk.com/eagle/ulp?utf8=✓&q[title_or_author_or_description_cont]=SVG&button= and select the latest version, currently 1.4.1

- Select location of saved SVG file in the eagle2svg dialog box and save the file

- Open saved SVG file in Inkscape

- Create cutlines for the stencil outside the dimension line and choose a color (different from the stencil cutouts (pads))

- Note: do not use black for ANY object

- Note: do not cut all the way around the stencil or the fan will blow it off the bed

- Use guides to ensure alignment of cutlines

- You can avoid cutlines by cutting the mylar sheet to the desired size in advance

- In this case, omit layer 20 when exporting

- Add any text or labeling and choose a (different) color

- Select text and run Path>Object to Path

- Ungroup the stencil elements that were grouped by eagle2svg

- Continue to ungroup until all elements are separate objects

- Delete the dotted line (dimension) around the stencil objects if present

- Save the file

- Place a sheet of 110 lb card stock under a 4mil mylar sheet and secure to the crumb tray with flat magnets at the corners

- Card stock ensures the laser can focus properly and helps to keep the mylar flat and stable

- You can also check the laser output by observing how deeply the laser cuts into the card stock “wasteboard” - it should not cut all the way though. If it does, reduce the laser power shown below

- In Glowforge app

- Import SVG graphic and place it in the desired spot on the mylar sheet

- Rearrange order of operations if needed

- Use the following settings for each operation:

-

Stencil cutouts: Manual Engrave 650/45

- We’re engraving the cutouts to burn them out rather than creating small pieces of mylar that will fly around the inside of the unit

- Embossed text: Manual Engrave 650/15

- Stencil outline (perimeter or cut-through lines): Manual Cut 500/45

-

Stencil cutouts: Manual Engrave 650/45

- Select “unknown material” and a height of 0.01" (lowest allowed setting)

Enjoy!