Jules,

Can you reuse the jig if you mark the placement to be placed in the same position everytime you want to use?

Unfortunately not without Snapmarks. That is the place where they really shine, because they give the machine a way to recognize the jig, and they can correct for the orientation of that jig if necessary.

So no, for now, if you don’t have Snapmarks installed as part of the Beta, you’ll need to recut the jig each time.

(There is one exception to that…if you do not move the original jig, but leave it pinned in place, then you can save the file by going back to the Draftboard, reopen it later and it should still be aligned. But the minute you try to cut something else and move the jig, you have to cut a new one.)

Bummer.

Thanks again.

If you make your jig in a way that it sits in the same place each time, then you can.

(Just by way of example) - a full sheet of PG can be located in the same spot every time, there are lips along the edges of the tray that you can set it against. Same with the tray itself - it moves slightly but you can slide it to the extremes forwards and to one side.

If you create your jig so that it can be located as I described, you will get accurate placement every time. You may need to use more than one piece of material - i.e. if it’s something that needs to be centered with the tray removed, you might need to cut flat pieces to place on each side and in front of the jig to align it against the front and sides.

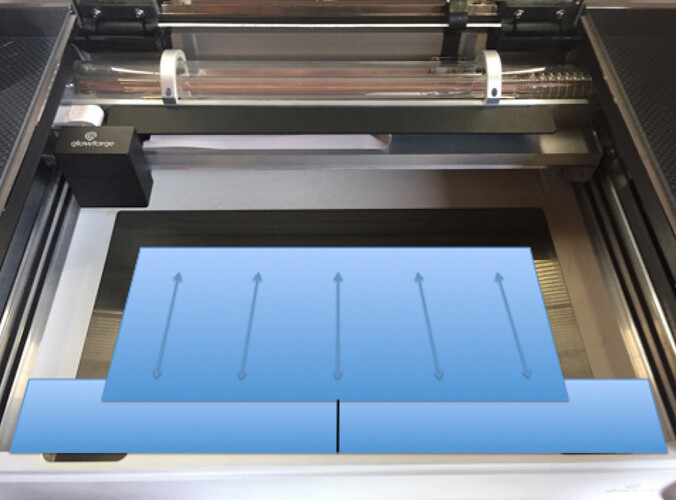

Something like this - two separate pieces at the front that slide up against the front and sides, with a cutout to locate the main jig piece in the middle:

This would work with or without the crumb tray.

If you do that you also have to lock the tray down. Just pushing it to one side doesn’t always work out, although you might get close enough for government work. ![]()

These boots are made for lockin’…

The first use I found for those 4" tiles folks have been engraving is to create perfectly parallel specific locations on the crumb tray that can be used to put your jigs or in my case all that 3" wide wood I foolishly bought thinking I could get 3" wide work out of it. This is done by working off the front chastity plate that if the door is closed tightly is always in the exact same place, and even not is at least always parallel to the movement of the laser.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.