I take apart computer hard drives and have been using the disks in various ways for art projects. Most of the disks are aluminum coated with a VERY thin layer of platinum or other metal. Some disks are made of coated glass. I don’t know what I want to do with them yet, but am wondering how to treat them so I can either engrave or cut them. I am assuming that if left untreated they would reflect the laser back up and possibly do damage. I don’t have my Glowforge yet. Can’t wait!

I have no clue, but I’m kinda excited to see what you and others come up with! I love recycling and creating new stuff. It will be interesting to see if the disks can be lasered.

Here’s the thing about being reflective, what is reflective in the visual spectrum is not necessarily reflective in the IR spectrum. Take regular mirrors for instance, they’re reflective in the visual but not in the IR.

Right! I have put a blow torch on them and they turn wonderful colors depending on the intensity and time. Too much heat and the aluminum melts. The glass made ones will melt and deform just like with a glass blower. It’s sooo pretty. So maybe the laser will just cut through like it’s not even there.

I don t know about the reflex issue but don’t count on cutting metal stuff. Engrave perhaps but cut no.

Cutting aluminum or glass with the GF isn’t possible, but engraving the top coat might be (as with anodized aluminum)

As is, hard drive disks are VERY reflective to a CO2 laser. If you take the metalization layers off, then you would just have a blank aluminum or glass disk.

You might be able to use cermark to mark it. Hmmm, question for people with cermark experience. Does the laser go through it and hit the material underneath?

I have seen where some people have made the mirrors for their lasers from the platters (but some discovered that the platters were glass - IBM Deskstar series), but most platters are metal. A magnetic will help to determine aluminum from steel.

Speaking of aluminum, check out the King Of Random if you want to recover and smelt the body of the drives (or pop cans and such):

You can use the GF:glowforge: to cut foam and then cast you own aluminum parts.

I made one Similar one for reducing bronze, but lined with 2,000° castable refractory and is gas fired with a blower.

Using an inexhaustible supply of beer cans, I want to cast aluminum ingots to turn a custom chess set… One of these days.

Thanks for the info. I’ll keep thinking.

Thanks for the suggestion. I was wondering about that as well. If I can mark the surface where I want the engraving then maybe the heat will cut through the thin layer of coating beneath. Maybe just scratching the surface will work too.

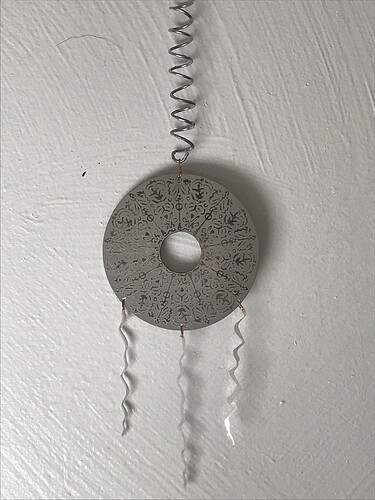

Success! It took a while to figure out how to get good consistent results and this is what I’ve come up with. I spray the platters with paint. It takes a few thin coats to get complete coverage. Some of the disks surfaces are so smooth that the paint will just bead up. I am trying now to heat them slightly so the paint will dry and be sticky when it hits. Still experimenting. I tried painter’s tape, but didn’t get consistent results, very splotchy. Once they’re coated the settings for the ones shown are 250 - 300 speed, 1000 power, 270 lpi, and .05 thickness. There is some variation that I assume comes from differences in thickness and materials. I then scrub with acetone using a strong scrubbing cloth, not 3M scotch brand which will scratch the shiny surface. I have gotten some really pretty effects when I slow the speed down more and then don’t scrub as hard. This leaves the etched parts black with the paint. I think the aluminum is getting pitted more allowing the blasted paint to stick better. Otherwise the designs show as a lovely aluminum grey.

They make really nice wind chimes and are very durable.

All the different parts shown in the pictures come from scrapped computers.

I have several disks, myself…hanging like a mobile. I know several people have wondered about engraving on them, as you did. They look lovely. I’m pretty sure that my disks are made of ceramic, though…are yours for certain aluminum?

Yes, definitely aluminum with a coating of platinum

Moving to Beyond the Manual - please be cautious, as I’ve heard hard drive platters are extremely reflective of infrared. That means they could reflect the beam, which could be hazardous to both you and your Glowforge.

Thank you for the caution! I was aware of the potential problem, but I think I have figured out a solution. I did many short test runs. I really don’t want to hurt my GF! The surface of the platters is very reflective, but also extremely thin. The surface coating is being abladed and the reflectivity destroyed by the paint absorbing the laser energy. The paint is bonding somewhat with the disk where the pattern is and has to be scrubbed away. Where the laser doesn’t touch the paint comes off easily and the surface is pristine.