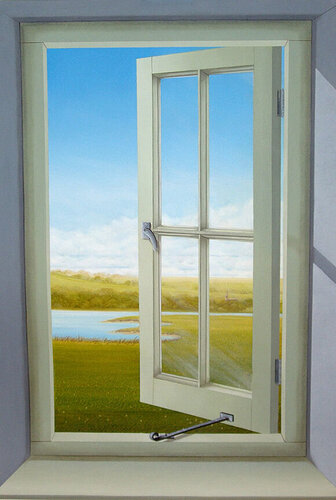

I have this kind of window where I’ll have my laser. I don’t want fumes getting back inside and I live in Canada so it gets cold in the winter. Any suggestions?

I live in Minnesota, yeah then there ya dontcha know.

2 options I could suggest, with personal experience.

- punch out a pane of glass. Hook your hose up and out the window. Make some kind of makeshift barrier to close off the rest of the open space. First thing you make with a glowforge is a plexiglass replacement pane with the hose hole cut to spec. Replace and seal with all weather window sealant.

This window stays shut while GF is in use.

Might want to get some cardboard set to insulate the inside, putting outside storm window or etc not an option. Depending on the tubing/piping of the GF, might need to wrap it with a blanket or thick cloth to prevent frigid air radiating coldness from the pipe.

I’m not sure if the venting pipe is removable, I can’t expect that @dan and others would want our sub zero temperatures to be open to the inside of the GF through the exhaust piping. It would probably make the inside of the GF very cold, to the point where I would worry about things cracking once the GF starts firing a laser.

So I went with option 2

- get the filter unit. 500$ is worth me not having to worry about the cold.

Thanks friend from the south (I’m from Manitoba, above you)!

Hadn’t thought about punching out a pane. That’s definitely an option!! The more I think about it, the more the filter is becoming attractive. Haha

If it’s a relatively new window the glass is all likely one unit with a grill over or inside the glass itself ( you’ll have to be the authority here) but I can suggest building some sort of wedge that fills the gap when the window is open. Then cut a hole in the wedge to run the duct. You can even throw a blast gate on there to prevent backdraft. I could also imaging the wedge to be accordion like so you can still close the window when the Glowforge is not in use.

I’d put in a wall vent. Just like is used for a dryer. Quite easy to do. A bit more of a challenge on the second floor but still not to hard.

Was going to suggest a vent through the wall but wasn’t sure if @JeremyNielsen was an owner or renter.

I like your creativity @markwarfel I think the wedge is an option for sure!!! I thought about a wall vent but I’m not sure if that’s an option (I’m still at my parents house ha-ha. It is an old Victorian house)

If renting, a chunk of insulation board that fills the whole opening with a vent through it would be my preferred option. Cut it for a friction fit.

Oh, that’s a good call. I’m going to start working on one!! Thanks!!

“Old victorian” would suggest old window in which case caeful removal of a pane should be a good option.

Freshly upgraded windows haha.

Jeremy, it’s a casement window as opposed to a double hung window. And I fixed it for you!

Also being from Canada – Alberta, mind you – I feel your pain of wanting to lase in the middle of winter. I didn’t opt into buying the $500 filter, because having heard that the base 40W will feature a standard 4" dryer hose, I intend to build my own filter box to attach to the end of the hose.

You can get activated charcoal/carbon on Amazon (normally used for fish tank filters) for ~$8 CDN for 3 lbs to filter the toxic stuff, and if you add a furnace hepa filter you get the sub-micron smoke/smells. You should be able to make something suitable for ~$30-35, depending how fancy you get with the ‘box’ part of it.

And install a pane of plexy in the insulation if you miss the light coming through the window!

Why thank you! Can you post an actual picture? I want to brainstorm this more haha

@robbie I’ve seen David / Make Something’s 20" floor fan video in the past, but I’d caution that his is made with much lower safety concerns (ie.- wood dust, pollen) that are much larger particles. I’d definitely suggest a person make something more properly sealed and, again, HEPA filtered than just a regular furnace filter attached to a floor fan.

You’ll definitely want to make something easy to replace the consumables, like the charcoal/carbon and filter. I like the second video. I might make a half-size version of that.

I like the idea of making my own filter. It does scare me a little considering that we’re dealing with potentially bad gasses. But man… its so tempting… I’ll continue to look into it. If anyone does it, let me know!!!

A few words of advice.

Never put your filtering on the discharge side of a fan. This keeps all of your “dirty air” at a negative pressure. Leaks go in, not out. So any leak you have on the discharge is filtered air.

Oh, thats a good point. Would not have thought of that!!!