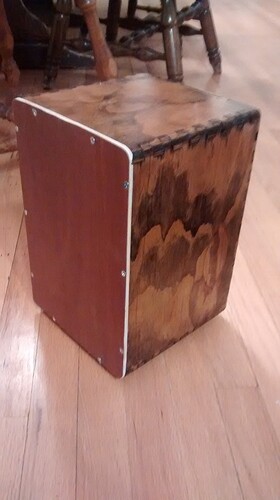

Some here may remember that I do a bit of woodworking as one of my hobbies. A second hobby of mine is performing as a Musician. Well, I also have a very musically inclined 2 year old. She can “play” every instrument in our house (as in hold them correctly and keep something of a tempo). One of the instruments that the band has is a Cahone (A box drum that you sit on and strike the front face to keep a beat) that I made a few years ago. That one is 18 inches tall and 12 inches wide and is quite a bit too big for a little girl to comfortably play.

So I decided to make her a much smaller one that is more suited for her. I also decided that this cahone needed to have box joints instead of butt joints. Mainly because I plan on doing box joints quite a bit with the GF and I’ve actually never used that particular joint before.

So here is my journey and pitfalls to making that cahone:

I decided her drum was going to be 12 inches tall and 8 inches wide (and deep) in order to keep the proportions the same as the larger drum. I also decided that 1/2 inch plywood would be plenty strong enough for this application. Easy. Cut two pieces in 8x8 Inch Squares, and cut three pieces 8x12 inches.

Then the box joints…I wanted them to be .5x.5 wide and high. So I meticulously cut out a piece of scrap wood that was .5"x.5"x1" large. I had a sketch of what SHOULD work (it was about 95% accurate) and that came out to about 144 little boxes that had to match up close to perfectly. So I very carefully marked all the boxes to cut out on 8 of the 12 sides (the front needs to be attached differently). I put the dado stack in my SawStop and it wouldn’t turn on. Turns out, I need to have the proper dado stack cartridge to run it and I couldn’t even get far enough to bypass the safety feature. Well, the easy thing is now out. Next up, router table and 1/2" flush cut bit. In my case of over 50 different bits, which is the ONLY one missing? the 1/2" flush cut bit. I could use a smaller one, but I felt that I would not be able to get precise enough. SO, I decide to put the main table saw blade back in and I’m going to use the miter sled and I’ll do this the slow and steady way. So 1/8" by 1/8" I cut out ALL the box joints. Slow, but I’m mostly happy with the outcome.

Not all the joints were a perfect fit.

But the majority of the joints fit quite snug.

I stained the main box with a dark walnut stain, and Used Natural Danish oil on the front.

Baby Feet for some scale.

And here it is next to it’s larger brother.

Overall I’m very happy with how it turned out, and I can’t wait for her to abuse this thing and maybe have to replace the front someday (it’s only a 1/4" plywood square screwed to the front).

Someday I want to learn how to make a tongue drum, that looks fun to do.

(If people are happen to be Googling plans it is spelled with a j… good ole Spanish word … you might get more results

(If people are happen to be Googling plans it is spelled with a j… good ole Spanish word … you might get more results