It is terribly frustrating to ruin material and waste time and money. We all get that. What I hope is that you can get better material and have great success. You obviously have talent.

I’ve been through this pain as well, I think everyone here will have.

If you aren’t willing to at least cut the Gift of Good Measure on Proofgrade material with Proofgrade settings, then you really aren’t trying very hard to find out what the issue really is. It literally only takes a few minutes to find out.

It seems she doesn’t have any proofgrade…as she deems it ‘subpar’.

Ah, a sewist, my kind of language ![]()

Sew, just like how in fabrics, not all denim is the same, this is also true for all materials such as woods. If I asked my husband to go pick me up suede at Joann he would probably get that cheap Alova stuff. I actually just asked him what he would pick up and he said ‘whatever is cheapest’…which is Sew Classics Alova and only useful for me if I was making fringe with it lol.

There are so many more properties to materials and your settings have to dial into that specific property. One reason why proofgrade is what GF support covers is because its a material set they know is safe. There are plenty of other safe materials and the proofgrade list is expanding but lasers is a relatively newer technology compared to that of the sewing machine. The most ‘dangerous’ sewing machine I have is a Sailrite (walking foot industrial machine) and that machine could pull my finger under its foot and drive a needle through it without skipping a stich. Although that would be really painful, its not as potentially dangerous the wrong material can be in the glowforge. Also, sewing machines have so much customization you do to tailor to the specific fabric. You can change your needle, food, thread, stick length, etc. on a sewing machine. If I was sewing 10oz sailcloth then I would probably use my sailrite and throw the monster balance wheel on it to have better control. That is completely different then the setup I would do on chiffon lol.

So basically, just how complex materials are for sewing, they are still just as complex for glowforging yet sewing machines have far more options to tailor to the material than the glowforge, which is a much newer technology than sewing machines.

However, the glowforge community has lots of SMEs of various skills and so you are on the right path to reach out to users. It looks like you already have a lot of great tips on cutting wood now. Hang in there because learning how to best tailor to materials is possible and there are lots of resources to help get there ![]()

You’ll get there! I felt the same in the beginning. It does take some time and I hope you’ll stick around the forum, there are lots of knowledgeable folks who are very open with technique and willing to point to more information. I really like your sign and I am looking forward to see what you do next.

Is it happening in the same place on every sign? I’ve been caught by path problems in Illustrator more than once.

If you decide to sell. Let me know. I love my glowforge pro. But. I clean my lens after each use. Even the one on the

Lid.

Hope you well with your journey. It’s a learning curve. I learn something daily

Carolyn.

Hi @nicole.balestrere I’m sorry to hear that you ran into some trouble with recent prints receiving excessive char. I would love to help you get this troubleshooted and resolved. If you’d like to troubleshoot this, it can help to have you run out Gift of Good Measure test print as other users have mentioned.

Print the Gift of Good Measure on Proofgrade material, using Proofgrade settings. If you’re out of Proofgrade, we can work with you to get some more.

When the print finishes, leave the lid closed and wait until the fans stop and the picture updates.

Check the completed print:

If the Gift of Good Measure fails to cut through, take a photo of the front and back of the print and attach these photos to your reply.

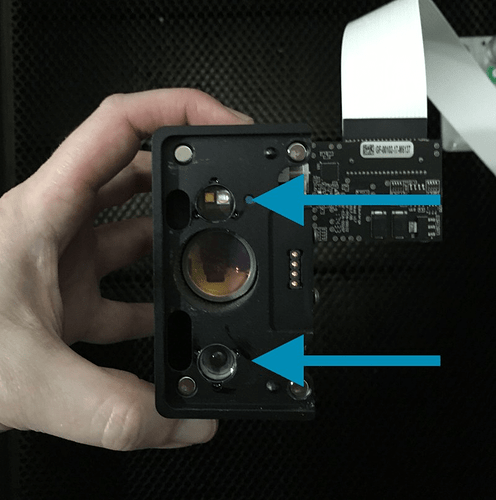

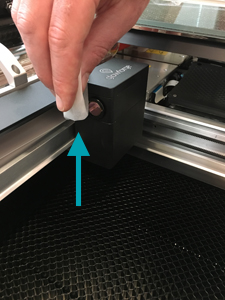

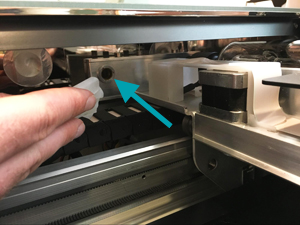

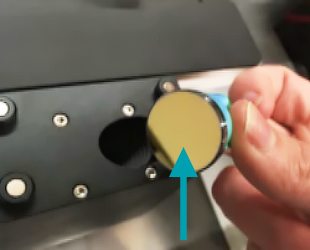

Also it can help to get a better look at the optical parts of your Glowforge to rule any of those out as potential contributors with the encountered print trouble.

Both windows

The printer head window, on the left hand side of the printer head

The laser window on the inside left of the Glowforge

The printer head lens

Both sides of the lens, top and bottom

The mirror inside the printer head

The bottom of the printer head with the lens installed

Feel free to post those in any response and I’ll be happy to review everything for next steps. Thank you!

Now this spoke to me!!! Thank you!

Hello

I have been using this product with my GF and have had a lot of success.

10 Pack | 3mm 1/8th inch Premium Baltic Birch Plywood, 12” x 19”, Glowforge Ready, Hand Selected Grade B/B, Unfinished | Boxes of 10, 20, 50 and 100 Available, for Laser Engraving, by Craft Closet

Return window closed on Aug 21, 2021

Sorry…

I purchased on amazon.

Thank you so much! These along with proof grade are too small for what I need them for.

I actually determined this is not the right laser for me. It is just not powerful enough nor can it handle what I need it to. So I gave it to my nephew and we got a big boy 8’x4’ flatbed laser for the shop!

Thank you though. What I found funny were the people that took my frustration and comments about GF personally! I hope you guys own stock in the company!

One of the first things I purchased when I bought my glowforge was some HD Birch. It was the worst wood I have ever used. I keep this photo as an example of going overboard in the strength and the laserproof filler.

LOL

No stock but I don’t use mine a lot. It seems though there is a lot of repeat problems with these machines. I cross my fingers each time I use it.

Best of luck

I do a lot of large prints too, and yes it’s frustrating but as for the smoke and charred burns, I sand all of my wood after to get the marks off. Yes it’s tedious but it’s worth the aesthetic appeal.

As for not cutting it through, I also have noticed that I have to tinker with manual settings for anything non-GF grade. You want to get a caliper and measure the thickness of your wood to ensure that it’s correct with your setting… the settings I use and have found it to be consistently effective are: for 6mm baltic ply, I use manual thickness to be .22" distance with full power and at 130 speed with 1 pass. You might want to play around with this before doing any large cuts.

Happy Cake Day. Don’t stay away for another 11 months.

We can’t discuss settings for non Proofgrade material anywhere but Beyond the Manual. You can remove the settings or I can move your post.

This is a discussion forum. It has sections to organize different types of discussions. The section in which settings for non-PG-branded materials are discussed is called “Beyond the Manual”. There are thousands of discussions there, with tens of thousands of replies, covering almost anything in the world that can be cut or engraved with a laser.

One of the most knowledgeable, courteous, and helpful owners here on the forum. You are fortunate to have been offered their help.

false

also, false

Hi @nicole.balestrere@yahoo.com. I see you reached out directly to address this through email as well. We just sent a response to that email, so I’ll go ahead and close this Community thread. Thank you!