Is that Pro or Basic Full power?

Basic

I’ve never tried anodized aluminum, but dan has said that the key is to be measure the thickness precisely. Some materials are more sensitive than others to the focus height and supposedly aluminum is one of them. Good luck!

We are wanting to do business cards as well but seems like everything comes in sheets, did you cut yours or were they pre-cut? If they were pre cut can you tell me where you got them?

I got 10 business card shaped pieces ordered from amazon:

I ordered them from Amazon. They come in several colors and are very good quality.

https://www.amazon.com/gp/product/B01LMWY8S4/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

edit* great minds think alike…same link as @atlwcb5579 posted

awesome! thank you so much! When etched is it silver? We are trying to find something that is black and etches gold or gold that etches black

Yes. When you etch aluminum you are just removing the colored “anodized” portion, which leaves bare aluminum.

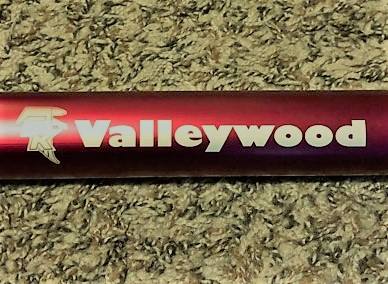

Here’s what it looks like, not really silvery. I don’t think you’ll find much like that gold and black combo you’re looking for. I’d love something like that, too.

You would have to use 2 layer acrylic for something like this. You can get the sheets in the same thickness as those business card aluminum blanks.

I wonder if it would be worth considering the possibility of re-dying the freshly exposed aluminium ?

If that could work, it would open up a lot of possibilities - laser/dye/laser/dye. . . etc.

The actual process of anodising is straightforward, and is certainly possible as a diy project.

Set up well, it ought to be economically feasible.

IMHO.

I would be pleasantly surprised if you could do this without damaging the first layer; but, I’m skeptical.

So would I, but it might be worth a try, given that it would be a simple experiment.

It might be as simple as dropping the item in a warm(?) dye bath immediately after the laser has done its work.

Otherwise treat it as a new object.

Given a fresh aluminium surface, a low voltage power source(battery) a dye bath(not sure what temperature) you’re good to go. Build up an oxide layer on the exposed surface, then into the dye bath.

The existing dyed surface should be resistant to any other dyes, and once you’ve got a good electrical contact to an inner surface of the metal, I can’t see any obvious difficulty.

![]()

The batons are coated inside and out. You’d have to remove some paint on the inside to get contact to inner surface.

My black anodized aluminum biz cards are black but when engraved appear gold-maybe it has to do with settings

These look amazing, what settings did you use? I just tried to engrave on some andonized aluminum and noticed when I took it out of the glowforge the pieces were very hot. Do you experience the same thing? Wondered if that was normal? Thanks for your feedback

Technically speaking, non pg settings aren’t supposed to be discussed in this category.

The good news is that it’s been talked about a lot, here:

Happy engraving!