Others have suggested isopropyl alcohol…less chance of warping.

Now that’s a great idea - assuming you have a profile for your scanner. I have a tool to profile my monitor, but I never got the full Mony kit to profile the printer as well. Maybe one of you folks have that and could give this a try.

I would assume the scanner was linear, certainly much more so than engraving. When you use greyscale there is a lot more leeway than in RGB. For the colours to look anything like the scanner would need to be pretty linear.

I appreciate you sharing your thoughts and building up this thread. Please continue to share your findings!

I think my next test will be with PG hardwood. The Layering effect I saw with the ply shouldn’t be there, so I am thinking I may be able to get a wider dynamic range.

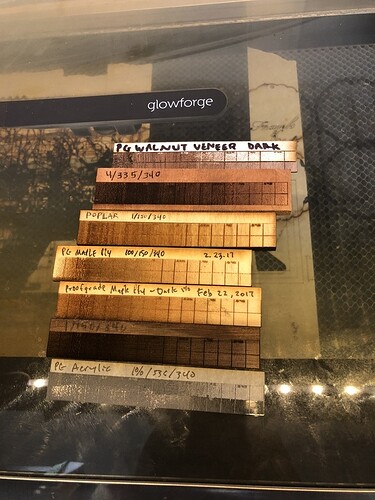

Can you share some more details of what you’re doing there? Looks like you have a better dynamic range than what I was seeing.

Basically I have a small gradient file that goes from black (0,0,0) on the left to white (255,255,255) on the right that I run on each material to see how it comes out with that power/speed setting. That way I will know if it will give me a good dynamic range before doing a whole engrave and having it turn out poorly.

I write the settings on each piece as a reference for later when I go back to use that material. I started writing the date as well, because sometimes GF changes the software which causes different output (or at least they did during the PRU phase).