If you need something laser cut urgently, let me know, I’ll gladly help you out.

Yes, helpfully it is fixed in production units. I gave up lasing tonight. It was over an hour trying to start the job…

Thanks Joe. Not that urgent. I can print the box at the lab if necessary

Moldlay is a pain. I can’t get it to print anything less than 100 microns. I use a bed temp of 65 C and a nozzle temp of 200. My nozzle is 0.3 mm.

With anything at or over 100 micron layers it is beautiful.

On the single life thing… The HP dongles work on the apples but for less yhe price

well, this pretty much sums it up, I get it to finally not clog…

Some days the best thing to do is stop, grab a beer and start again tomorrow. Hoping for better luck in the morning for you

That stinks! Cool to see on video though

Sounds like a pretty rough day … hope today is better!

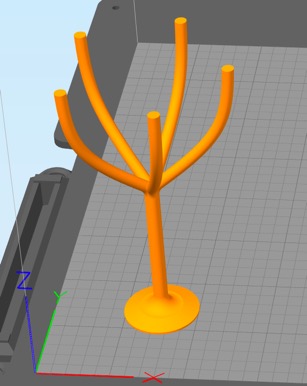

That is…seriously rough…but I’ll tell you, whatever you were making before the printer head decided to waltz the print all over the bed, it looked really fascinating. I hope it decides to stop throwing tantrums and cooperate for you today, your builds are always amazing

have you tried BuildTak for a print surface? I’ve been using it on 3 of my printers for 2 years and it is amazing. I usually have a hard time getting prints off.

I just bought makerbot filament to use in my Monoprice Maker Select because I thought the discount stuff I had bought previously was too inconsistent. I was getting bad prints all the time.

At some point (I am guessing about 2 hours in) after I left it there was a jam, the gears that feed the filament into the print head turned the filament basically into dust. It ran for at least 11 hours without filament. Now when I heat the printer and feed filament in, its hitting a blockage. I’ll need to disassemble and figure out how to remove the jam and how much damage was done.

I feel your pain.

Oh, man!

If all things in the universe are truly connected, I hereby will you some better luck!

Don’t know if it helps or not…the new Simplify3D version 4 is out, and it gives you the opportunity to weight the base infill (you can set up variable infill zones) so that really tall objects don’t get top heavy and get knocked over or topple.

I haven’t upgraded to it yet, I just got the mail-out. (So it might not be ready for Prime Time yet. But it looks like it might be helpful trying to print something like that.)

(And you could try adding an attached skirt or raft on that design…really broad at the bottom, to give more surface adhesion area to the shape. It looks like it might be top heavy.)

This was using V4… Just that wax is very slippery…

Bummer. (Let me know how you like v4 otherwise though - I haven’t installed yet.)

This is not cheap non-name filament, but essentially it’s paraffin wax which is really slippery stuff. I normally get fantastic adhesion (I have plenty of tearouts on my glass where the part stuck so well that while cooling tore a flake off the borosilicate…

I did get a successful print in E3D scaffold (modified PVA) I designed the model to not need supports.