Greetings -

Thought I’d do an update for the latest ‘experiment’, along the same lines inserting acrylic into a print. This time, I wanted to see if I could print ‘on’ fabric. I figure Felt has probably the best shot as it’s basically a kind of plastic, and mabey the 3d print filament will melt into the surface and stick. One way to find out.

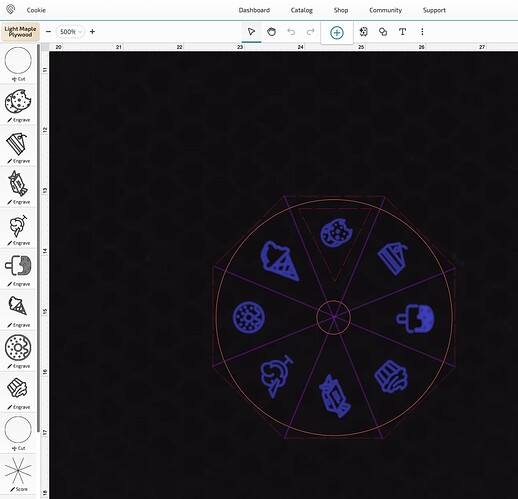

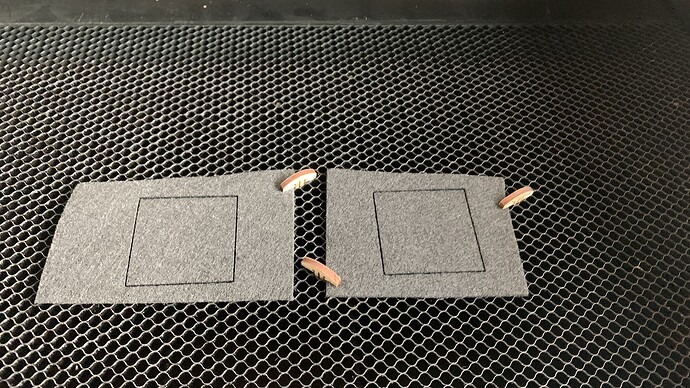

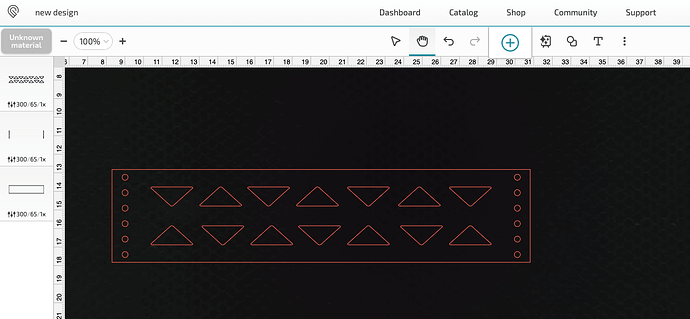

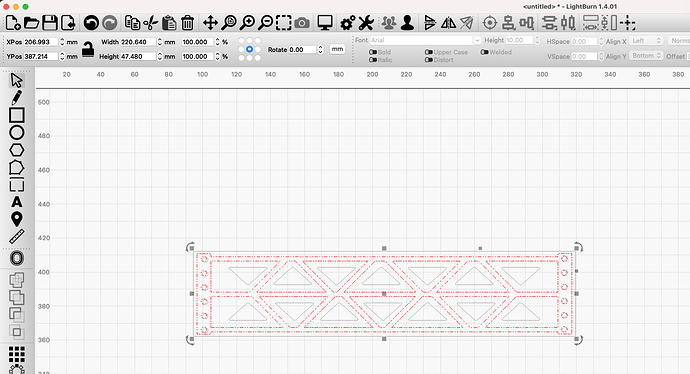

I GF cut a 50mm square of felt to be the test piece.

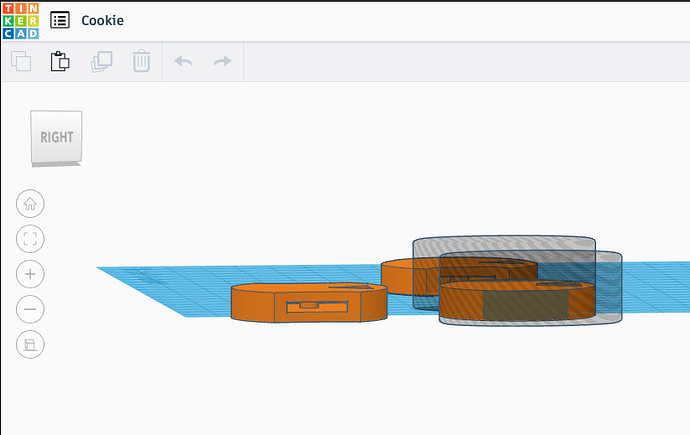

I put some 2-sided tape on the back to stick it into the ‘mold’ and get it to stay in place long enough to print on.

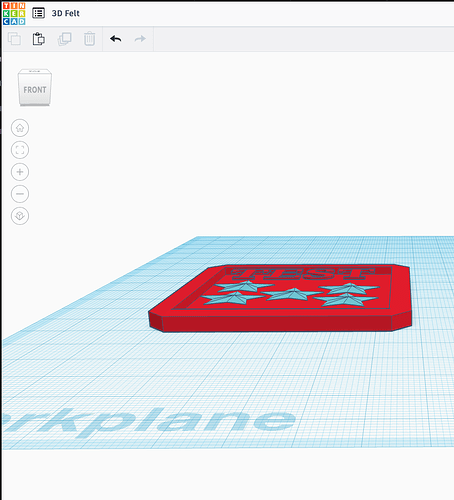

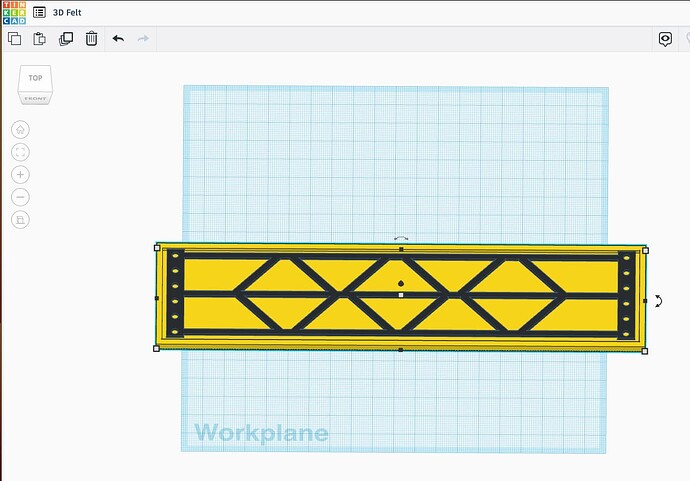

I made a short ‘tray’, with now floating elements on the first layer above the support base, and on top of the felt. Hit print.

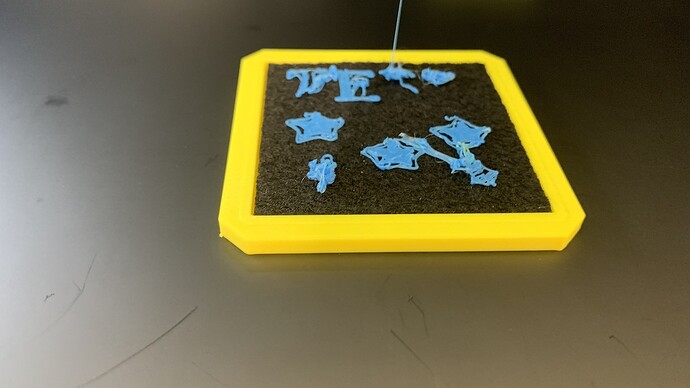

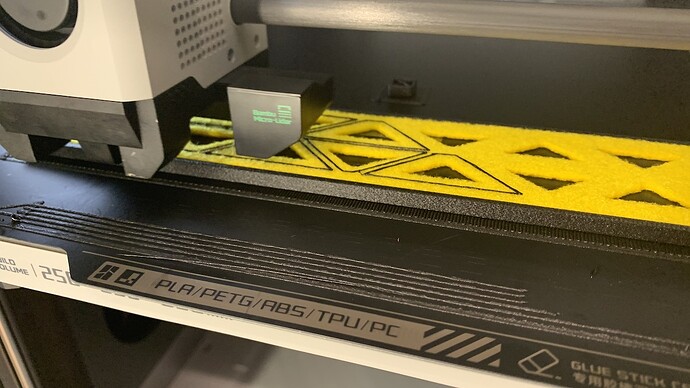

So as before, once the filament change starts, I inserted the felt

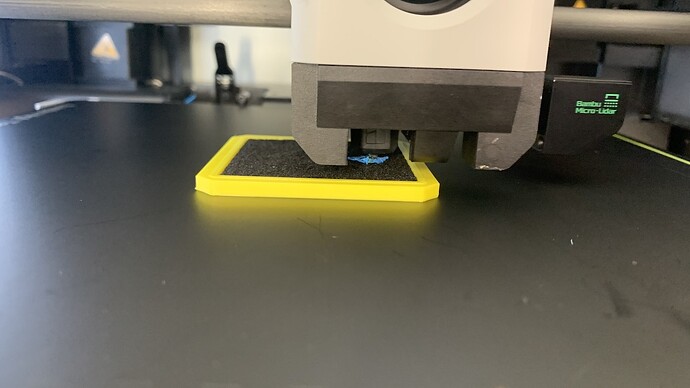

And the printhead comes back in blue to start the graphics on top of the felt.

I was using PLA, the standard (low melting temp) filament, and it was clearly not hot enough to melt INTO the felt. I didn’t even let it finish because after just the second layer, well, the photo speaks for itself.

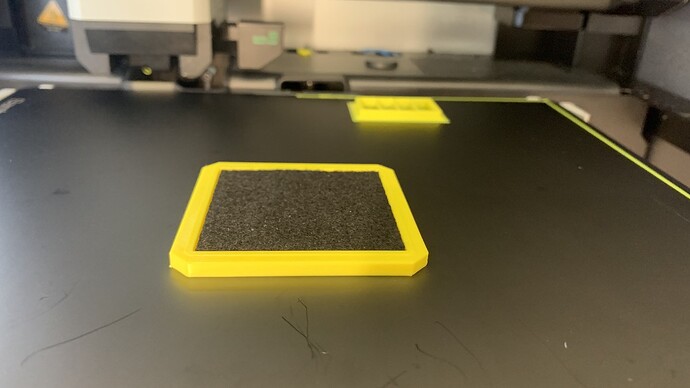

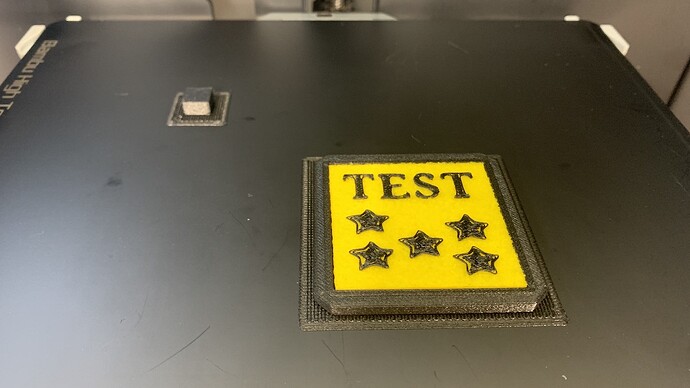

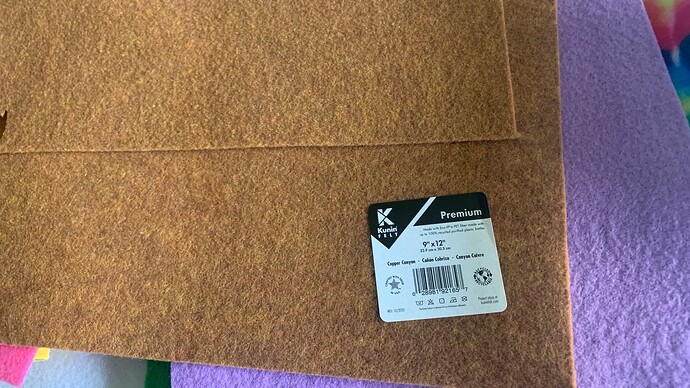

I have some PAHT-CF filament (hotter melting temp) already open and on-hand so let’s give that a shot. These hotter melting temp filaments are far more limited in colors, and I only have black, so I cut new squares in yellow felt.

And here we go. Wait until the tray is printed to the right level, insert the felt, and see what happens.

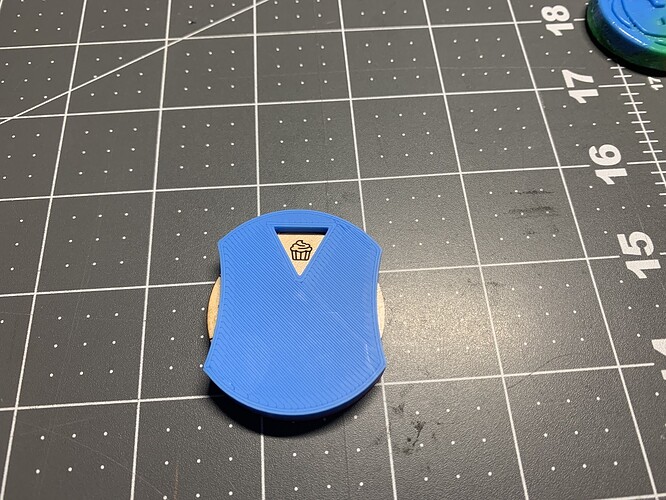

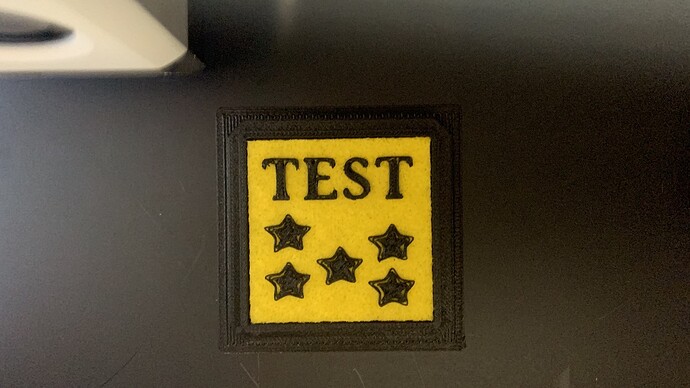

This looks promising. The stars were ‘pointed’ and super thin, which is causing them to not be filled in all the way. But the letters look pretty good.

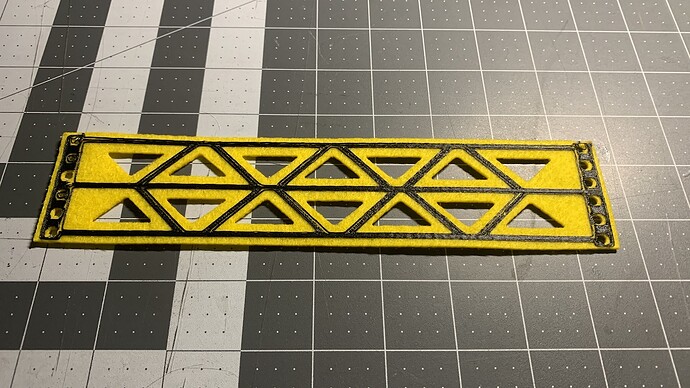

It’s done, and let’s see if the graphics melted in and stuck.

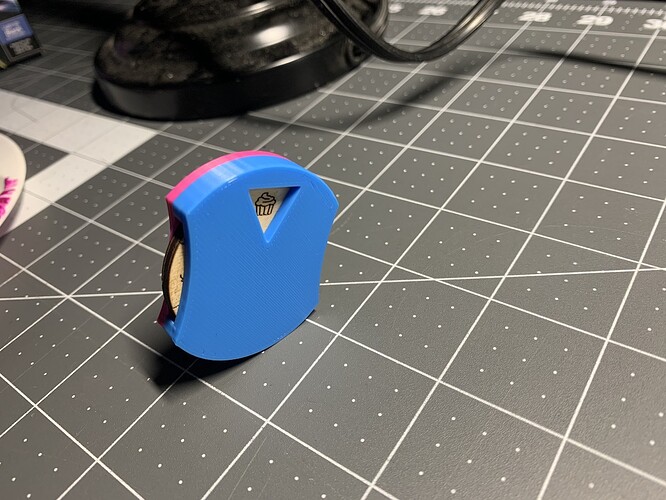

Not perfect, but not bad either. The letters were .7mm high, so only a few layers. But they did stick, which was the point of the test.

I would call this experiment mostly a success. I think the felt was a little thinner than the gap I made for it, so the letters and stars were more deposited onto the felt, as opposed to being extruding into the felt. And they peel off fairly easy. But I believe with just a little more trial and error, it only gets better.

HL

![]() But I use the other for the crates.

But I use the other for the crates.