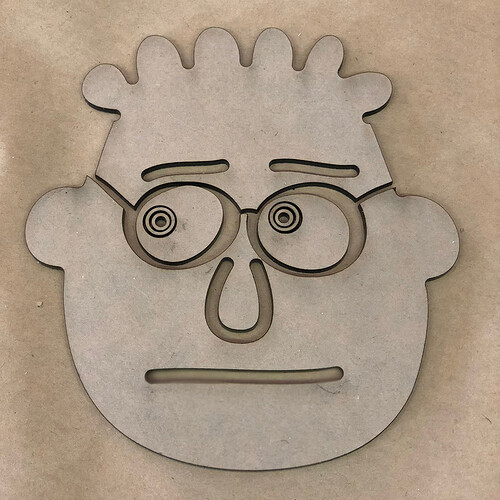

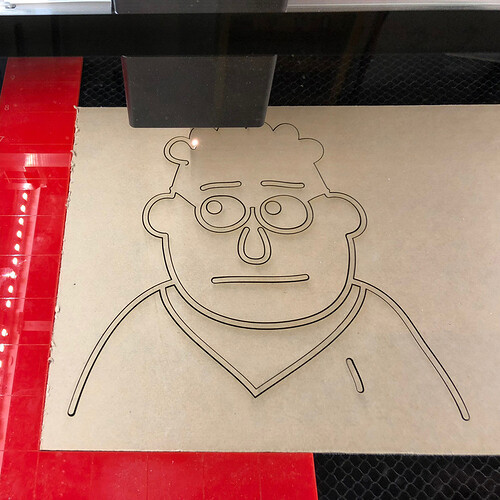

I made a version of one of my drawings insetting black acrylic into plywood. An 1/8” groove was made in the plywood with my Inventables X-Carve CNC router and the acrylic black line was cut with the Glowforge. The pictures show the final product as well as the face being laser cut and the material that was left over.

Looks great! Nicely done!

Oh my, that worked so very well! I wonder if an X-Carve isn’t somewhere in my future?

I’m not sure if an X-carve is or not, but a router based cnc is. It is only logical for you to round out your super maker status this way.

Shooot! That’s all I need is another toy! I’m still exploring this one.

Join us cool kids and get a Shaper Origin.

What is that? Google results show all manner of crustaceans, but somehow I suspect that’s not what you meant?

fixed so this looks weird now.

I was thinking this but I don’t want to become the pusher for SO that I am for Fusion 360!

I figure their forum needs traffic, and someone who will actually post the projects they’re making with that tool. It’s amazingly quiet over there despite folks with units in hand but I know @Jules would take care of that.

I believe that was an insult! (You callin’ me a chatty cathy?)

No, he’s saying that you add value on any forum, and the SO forum could use some of that. If dan is not sending you a stipend for what you do here he’s being short-sighted.

All I’m sayin’, is I am an overachiever… and you leave me way back in your wake.

Oh okay, that’s all right then …

(And my integrity is such that I can’t be bought.)

Could probably rent me for a while for  though.

though.

I like it. Is there a reason why you didn’t laser cut the wood too?

Great question – My wife asked exactly the same when I showed her this post. Can’t speak for the OP, but I’m guessing speed and accuracy (of depth).

Engraving shapes to an exact depth is one of those things that’s just easier with a router (CNC or otherwise). I’ve tried my hand at inlay a few times since receiving my GF and it can take quite a bit of testing to find the sweet spot of pews/zooms/LPI to achieve an exact depth on a given materials (and you have to re-test every piece). A CNC allows you to just say cut this shape to a depth of exactly 0.125" and it will do it.

“Hollowing out” the empty space is faster too – a 1/8" or larger end mill will remove a lot more material per pass than and laser beam (~0.004" ?).

I was trying to decide between a X-carve, Carvey, or Shaper when I saw the GF. Super happy that I got the GF, but am now back to hankering for a CNC, too!

The maker trifecta – 3D Printer? ![]() Laser cutter?

Laser cutter? ![]() CNC?

CNC? ![]() (so far)

(so far)

Bruce3 is correct. Also, I wanted to cut completely through the plywood and it was thicker than 1/4". In addition I was curious to see how consistent the dimensions were between machines. I was surprised to find that the Glowforge cut pieces snapped into the X-Carve slots with little trouble.

In my previous post I meant to say dwardio was correct.

Absolutely amazing

I can’t wait to do the same, integrate my work between CNC and GF.

Really Fun!