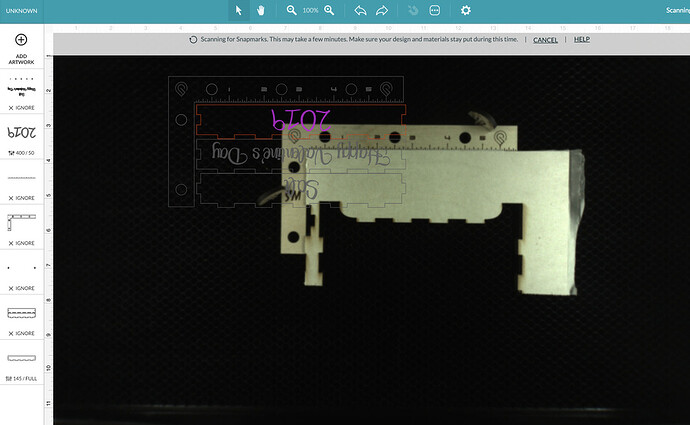

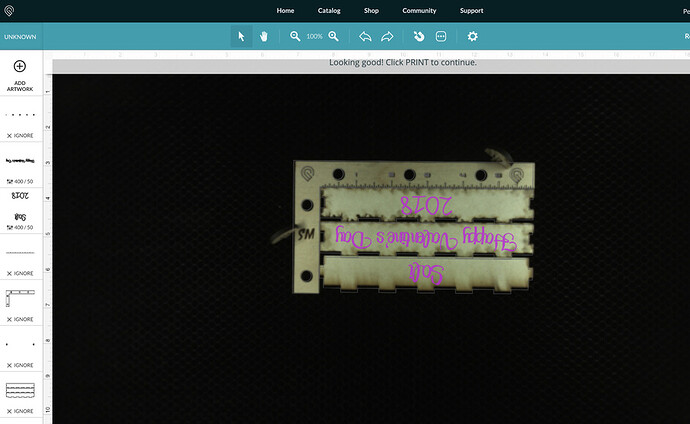

I don’t even think I’ve even posted in the forum ever, honestly I’m not much of a poster. But, I do peruse through this forum quite a bit and for Christmas, GF gave me Snapmark(s). I did the tutorial a couple weeks ago, but today I actually took the time to learn it and apply it. As you can see, just making some V Day boxes for the kid and I forgot to engrave the lid components with her name etc. I really wanted the text to fill as much of the piece as possible and was about to toss the pieces (cause there is no way to be this accurate by just engraving over this smaller size piece), when I remembered the SM tutorial and the jig I downloaded a while back thinking “this looks like it’ll be useful.” ![]()

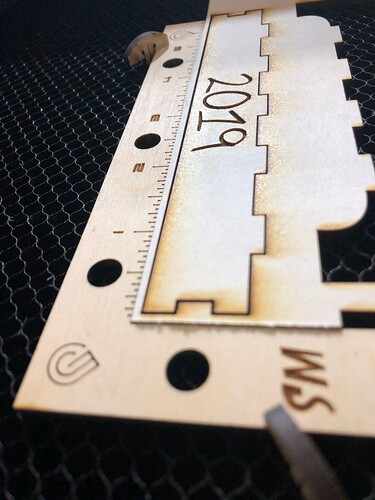

Anyway, I got to test out cutting a part as well.

…Due to thinking it’s still 2018 apparently (I think we all do this for the first two weeks of January). I was confident I could cut the piece I needed with this SM tool.

So - this is a feedback post to staff regarding my personal impression. Today snapmark proved to be invaluable (I’m forward thinking about all the saved material and ability to be very, very accurate). Not too complicated and a feature definetely worth having. I really hope this is something Glowforge is leaning towards keeping and completely rolling out. Thanks for letting me test it out!

I’ll also take the opportunity to thank the ideas I stole here/pictured as well. What awesome additions to the GF workflow and a very generous contribution. Hopefully I do this correctly…