do you know where i need to sign up

Unfortunately its a sit and wait process. They are selecting the easiest machines first to enable it on.

OK Thank you so let me sit and wait like always

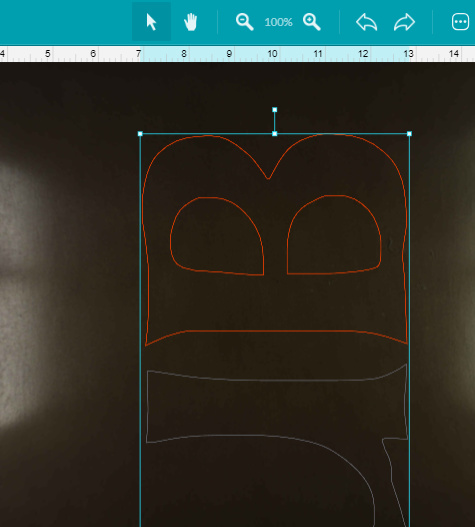

FINALLY got snapmarks to work. The trick is that in Inkscape the size stated doesn’t work.

With scale at 96, the size of the snapmarks needs to be .343W x .417H instead of the stated .3322 x .4047

Thanks @bonny for all your help troubleshooting this!

Now THAT is a handy little piece of information! I can’t wait to try again tonight, as they’ve never worked for me. I have to admit I’m a little excited because I’m an Inkscape user and experienced the same behavior you related (it looked like it went right to them but then said it couldn’t find them).

this is the kind of thing that makes me wonder about using SVG vs something like PDF, which i don’t believe has this kind of issue. SVG was originally designed for the web, not for print. PDF is built for this kind of thing.

I’m more curious if the preferences aren’t set to include the stroke width in the dimensions, which would be an issue with PDF or SVG.

So did the file I uploaded above not work in Inkscape? I was hoping it would help people having the same issues I did (and you, too)!

your file was the breakthrough we needed! I had forgotten to try it the night that I had found it.

so the 96/72 thing with inkscape again?

I thought that the GFUI loaded at 96?

hey @bonny - can we have snapmarks pls? unit tvv-297…

(wife is the owner, she’s supposed too email you about changing that, and removing the unit we returned…)

No. It was a selection in the preferences that included the stroke width in the object width so the actual width was unexpected.

I’ve never seen asking help get things faster

Grams used to say - don’t ask, don’t get…

Hey! Down here! Please can I have snapmark!

Hey! Down here! Please can I have snapmark!

There, two of em!

There, two of em!

It seems like the 'OMG PLEASE ADD ME TO SNAPMARKS TESTING" posts have slowed down over the last few days…so…

OMG PLEASE ADD ME TO TO SNAPMARKS TESTING

Snapmarks would have made my 8’ long 9" tall sign project a little easier…

(printed on machine HRY-788-3 in March - Belongs to my son - KickStartede Machine), my machine YCY-287-3 will have a similar job to do soon, I hope the magic appears before I close the deal

Basically, I burned one letter at a time, and uparrow aparrow a gazillion times to move next letter up after pushing 1/4" ply forward for next cut. I aligned the cutout with the art in GFUI press print for the next letter.

I had 3 different signs, each adding complexity, started off as a 4’ sign… clients never wrong…

anyway cannot wait for the new tool

That is basically the method I have used. If you use only the up arrow it stays aligned and any error is only in one direction and usually not bad if under a millimeter which it usually is.

Only when you need to cut at exactly the same point does it become a problem.

…and, of course, everyone knows you can hold down the shift key while pressing an arrow to reduce the number of key presses by a gazillion/5 or so, right?

Ya sure but

Keyboard shortcuts dont grant the machine functionality

…

We received our first machine in Dec 2017, and have shift clicked many images into position.

Paitently shift/clicking