You should try using the bed rulers. Line up your jig the same way each time, and as long as you don’t move your design, you’re golden.

everything we’re trying to do is custom… so, its’ one or 2 shots. getting closer to one, but amazon-cardboard is a prized commodity here… but in any-case, the glowforge folks sold a ton of units on what is essentially ‘false advertising’. They ought be glad that lawyers are not creative people…

I don’t cut a lot of jigs unless I’m going to do multiple copies of a project. I do use the 5 power high speed score on a piece of copy paper. Then I put the piece on the copy paper in the score line. Or if I’m doing something on PG or masked material, I’ll do an even lighter outline score so I can see where it lands without cutting through the masking.

How would you guys recommend aligning a passthrough project where the item to be cut is a continuous 26.5", in other words, it is 1 object which is cut in 3 sections which must align perfectly. Thoughts?

I’d probably cut it in four or five sections. (It’s a lot easier for it to get out of alignment on longer runs.)

I’d use snapmarks if I had them, or just use index marks and the side of the tray to anchor to, if I didn’t. But I do believe I would just set up separate files for the sections now…it’s bound to be easier to handle.

I have snapmarks and don’t use them for pass through. Too much trouble. I just index the part forward and cut the next. I get results within a mm or so. If I needed sub mm tolerances I’d make a permanent acrylic jig and include stop marks in the file or use the snapmarks.

hi glowforge people!

I’ve been using snapmarks for a while now and they’re pretty useful. The biggest problem I’ve encountered is that if I go over a certain complexity level, the alignment goes wonky or fails completely.

My message is mostly feedback, as I’m glad to have the snapmarks even with their limitations; but if anyone knows otherwise, please speak up. Can snapmarks work with complex real world data?

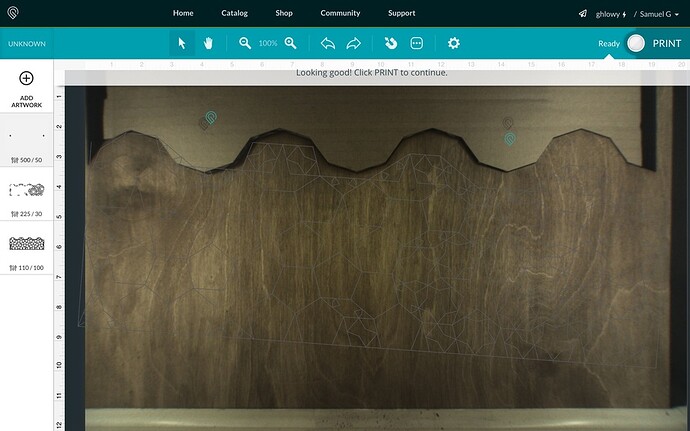

I have been using the snapmarks for about a month now, with no issues, until today. Recently, I have been receiving a pop up saying “everything looks good,” after clicking on the snapmark icon for alignment. As of today, I’m no longer getting that response, it just says “ready” and it’s taking about 4 times longer to supposedly align. However, it’s is not aligning properly. I tried shutting everything down and restarting, but I still have the same issue.

Thank you in advance for any help or suggestions.

Amy

Hi,

I’ve used snapmarks before and they’ve always worked great for me. But tonight for some reason they aren’t working. Here’s the scenario:

- I load the snapmarked jig into the glowforge and close the lid and load the snapmarked SVG

- I get a good image of the jig in the bed

- Then I click the ‘magnet’ button to scan for snapmarks

- The bed image goes black as it’s scanning for snapmarks

- At some point the head homes to upper left and starts grinding for a few seconds

- The status changes to ‘read to print’

- I’ve tried power cycling the GF a bunch of times.

- I’ve tried power down, them moving the head under the lid camera and powering back up.

Hopefully some one can help me out.

Yes, it can, that doesn’t appear to be that complex. The problem in your case might be that the cardboard you’re using looks like it’s got some warp or bowing to it. Might be impacting things in that case.

Every time I had that happen there was something out of whack in the file. Did you try it with a different file that you know works?

I’ve seen that happen a couple of times during the testing, usually when the machine has gone into sleep mode, and oddly enough, if you just go ahead and hit Print, it lands right where it’s supposed to. I would suggest testing it on a cheap piece of cardboard or scrap just to make sure you don’t lose material. (Or you can just cancel the print, walk over and open the lid for a second to turn the lights back on, go back to the dashboard, then reopen the file and snap it again. You shouldn’t have to recycle the machine.)

Hi @bonny snapmarks seems to have made my Glowforge slow… not sure how that can happen but the Glowforge has gone slow suddenly. If you think it could be another reason then please let me know.

Thanks

Hi @designersdeck, Snapmark itself should not affect the speed of Glowforge. Is the slowness a new issue you just started noticing in the last day? Is it still happening now?

I used it a couple of days back and this was happening just at the time when I first used the snapmarks. I haven’t used the Glowforge since so il try it today and see if it’s still happening.

Hi All! Tried Snapmark for the first time last month. I followed the instructions on downloading the pencil jig, being extra careful not to change the size of the snapmarks. I had to read the instructions a couple of times to familiarize myself with the steps, but when I got down to doing it, it was pretty easy to do. I liked that I could change the design and print it out without having to realign anything. I thought the designs were accurately placed with much more precision than what I could have done manually. I don’t have the need yet to use this feature on a regular basis, however, I really like what it was designed to do and hope that it’ll be a feature that Glowforge will keep and make available to everyone.

Wow! I didn’t know Cupid could shoot the Glowforge with an arrow! Lo and behold, I awoke to Snapmarks! Thank you so much. I did a quick paper cut design to see if I maintained Snapmark integrity, and it worked like a charm. Can’t wait to seriously play with it this weekend on some jigs for double side tokens, multi-sided dice and printed shadow box card designs.

Thanks again!

Had you previously received an email, or did they just appear out of the ether?

I’ve been following the topic since it was introduced in September. Interesting to read the comments of those waiting for Snapmark. It is the tale of those with and those without. I am one without it.

I do not have it. I have a pro. I bought the pro model ,in part, because of the pass- through feature. Thus, I had a bit of frustration when my forge arrived without that feature supported. The announcement of Snapmarks looked like it was going to fill that feature gap, you even describe it as being able to use it to “align Pro Passthrough prints more easily”. But, it never showed up on my machine so that frustration has grown over the past 6 months.

I believe Snapmark might fulfill much of the promise of the pass-through feature that was part of the sales for the pro system and to address the challenges posed by the current state of alignment ( which is poor). While the current website does not sell the pro model thisway, it did in the past:

“Passthrough software uses the camera to maintain alignment as long material is pushed through”

This was not a 'some day" soft promise of future vaporware. This was written as if the feature existed. I believed that was what I was buying. I will suggest that rather than deleting the text from your site, as you did, you should have edited it to state that the previously described feature is is not supported. Otherwise, you leave customers open to believing what they read in the past but you have since deleted. It is harder to spot something that has been deleted vs noticing something new or something that has been changed. It is about being honest vs being sneaky. You chose sneaky.

I know that there are work-arounds for using the pass through on my machine. While they are not simple, I use them. Often with costly errors. A crappy alternative does not absolve glow forge from fulfilling the promised features (a partial refund might). I cannot be the only pro owner who believes they were duped on this. Now it is starting to appear that the issue runs deeper.

The odd way you are rolling this feature out is troubling for a few reasons.

1) Is my machine a dud? The “long answer” part of the “Who tests Snapmark” suggests that some devices are “easier” than others which have “noisy calibration data” and that some machines have “noisy calibration data that will not process with out further work”. So, as time chugs past with no Snapmark on my machine, I become increasingly convinced that my machine falls into “too noisy to snapmark” category. This is not something I can control. You designed/ built this beast so the calibration noise is on you, not me.

You indicated the “full process” may take “weeks or months” to fully deploy. The use of ‘weeks’ and “full” does not suggest ‘26 weeks’ and ‘some’. Without any word to the contrary, I have begun to interpret the long delay as implying that my Pro is too noisy to handle this feature. As more and more people report in as having it, that sinking feeling grows. When is the right time for owners of noisy pros to start discussion on having them replaced with models with better calibration? ( i.e. ones that can actually support the pass through).

2) You rolled it out to non-pro units. Non-pro users did not buy a unit with the promise of pass through support yet they enjoying this feature while some who actually paid for this functionality do not have it. Seems like there could have been other priorities given in terms of who and how you rolled this out. Options could have included, oldest units first, pro owners first, big referral sources first, big spenders in the shop first. You picked " machines that can handle it first"

3) lack of communication on the progress. Over 6 months later, and scant info on the progress has been made available. This increases the frustration even more as on only helps to suggest that things are not going well for the machines with more noise.

The way you have handled this suggests an attempt to confuse and deflect on this truth: the core glowforge design cannot support Passthrogh on a large number of machines already in the wild. I double dog dare you to prove me wrong.

Things you could do to make this less of a cluster:

- transparency, how many machines have it out of how many?

- let people know where they are in the queue and when they should expect it

- give people a way to see how noisy their cal data is relative to others

- openly address what you will do about machines with high calibration noise

- or better yet, release reasonable passthrough support

That was a polite rant and right to the point and reflects the thoughts of many of us.

I commiserate and if you look at my post history you will see I am no defender of how the company does a lot of things.

But I disagree with much of this list:

If they told us “how noisy” our data was, and revealed the queue, and told us how many machines are in the test group… That would spin up flaming threads on those topics. “Why did he get it before me when I bought my unit before him and my data is just as noisy as his is?” We would generate a tremendous amount of waste heat on discussions like that and it wouldn’t make us feel any better.

In my opinion, those arguments would not help us reach our goal, which is:

As a long time forum resident, software industry dude, busybody, pre-order customer, and car wreck rubbernecker… personally I would love to see more about how the sausage is made.

But what we really need, us customers, is the frickin’ sausage… not a tour of the sausage factory.

If I were writing a list of demands/wishes/fever dreams/hallucinations, it would include just two items.

- What are we getting?

- When are we getting it?

![]()

We’re makers, we want to see how it’s made!