Laser cut a 3d printer

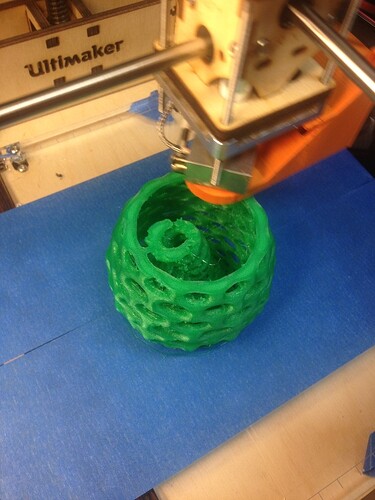

One of the first 3D printers commonly available was the Ultimaker.

It was shipped as a kit and the frame is largely wood cut parts. Including living hinges in later updates! I remember unboxing it and, upon realization that it was a laser cut frame that was super stiff, that I was looking at a revolution in kit making. Sure enough, there are lots of CNCs and other applications that use laser cut MDF or plywood for various components that need to be super strong!

They still sell it as the Ultimaker Original.

Yeah back when I first joined a makerspace I attempted to revive a makerbot cupcake that was made out of laser cut plywood, and of course there was the printrbot simple kickstarter (I bought that one when Brook moved to using metal).

I love the design aesthetic of 3d laser cut stuff. Needs a cool name like steam punk … plypunk?

Laser cut wood is a terrible choice for something like this. When I bought my Replicator Dual way back when, it was about the only choice. And it was cheap. But wood is not very stiff, and it changes dimension as a function of both temperature and humidity. The Replicator’s fasteners constantly loosened up and needed retightening and the machine never stayed calibrated, even over the span of a long print.

If you want a kit-build 3D printer, cut it from Acrylic and not wood.

I don’t think the intention is to compete with existing printer kits, it is more the fun maker challenge

Really even acrylic isn’t a great material for 3d printing quality (the Anet A8 design is a famous example of using laser cut acrylic to cut costs that has been widely replicated but superseded by extrusion based designs).

As long as your expectations are “level set”. I used my plywood Replicator Dual for many years with great success. But since I’ve replaced it with a machine that’s made of injection molded plastic and steel, getting good quality prints has become quite a bit easier.

Whatever works right?

Right now my go-to printers are extrusion based, although the main metal frame of my prusas are I think cut with water jet IIRC

My CNC machines are MDF and extrusion, with some printed parts

I still have an original PrintrBot, built from laser-cut plywood, among other things. It was my intro into 3-D printing. It’s long since relegated to back seat status by more modern printers, but it did quite well a few years ago.

I bought my printrbot when it went to metal, but I followed the company and brook before that. My first printer was a terrible, terrible machine (makibox), the Printrbot was my first that worked

For cutting wood and foam and stuff like that, MDF gantry CNC machines are great. I have a BlueChick machine with a 1HP router head that makes quick work of large chunks of Pine and Oak and Maple. For precision work or cutting metals, I have a small Taig CNC (weighs about 100LBs) with a 4th axis so I can get both sides of a workpiece. For 3D printing I have a RoboR2 FDM plus a Form1+ and Form2 SLA. And of course, I have a GF.

I was sorely tempted to buy a Wazer water jet when they kickstarted, but it was still a lot of money for what basically amounts to a hobby tool for me. I’m using Delrin for a lot of my designs now because it’s strong and the GF cuts is beautifully, but I want to incorporate Carbon Fiber and water jet would be perfect for that. But the Wazer kickstarter is long over and the current price is more than I can talk myself in to spending.

My GF is first of my tools that has paid for itself ![]()

This is my main CNC machine, as you can tell it is very DIY

https://www.instagram.com/p/Bu2CRxwHnK4/?utm_source=ig_web_button_share_sheet

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.