My wife (a skilled potter with her own studio) has been working on laser firing ceramic glazes. (She’s currently working up a proprietary glaze formulation specifically for this use.)

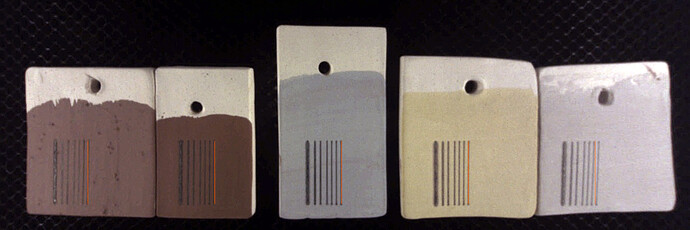

Here’s some test firings she did with off the shelf commercial glazes and her own proprietary (non-laser specific) formulations:

First is a five panel sampling using (from left to right): Proprietary Raisin Cone 6, Proprietary Black Cone 6, Amaco Obsidian Cone 5/6, Proprietary Gold Cone 6, Mayco Stroke & Coat Football Cone 06/10

The substrate is .250" thick bisque fired cone 6 white stoneware.

The lines were run as manual cuts, .250" focal point, at the following speeds (from left to right), all at full-power, basic model: 100, 150, 200, 250, 300, 350, 400, 450 Glowspeed

All the lines were fully vitrified.

After firing:

After the un-fired glazee was scrubbed off:

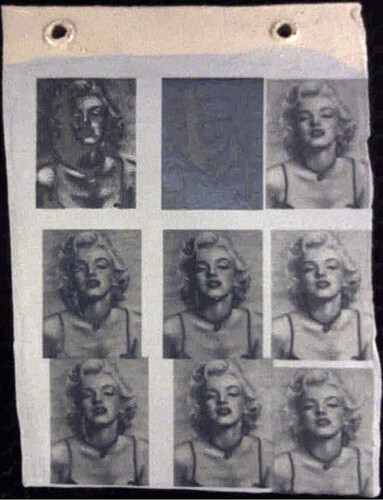

She also gave “engraving” a try. The following were all done on the same substrate with Amaco Obsidian cone 6.

After firing:

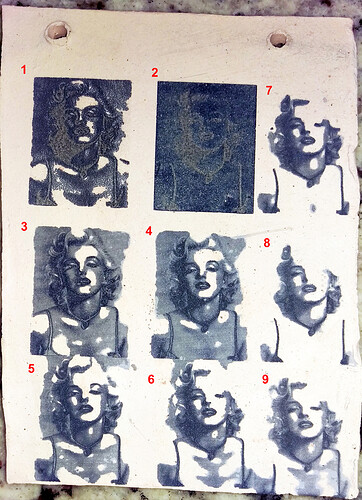

After the non-fired glaze was scrubbed off and firing number notated:

All were fired in manual at 340 LPI, .250" focal point.

#1:“Convert to Dots”, Full Power, 300 Glowspeed

#2:“Map to Power”, Full Power, Min 50, 300 Glowspeed

#3:“Map to Power”, Full Power, Min 5, 300 Glowspeed

#4:“Map to Power”, Full Power, Min 5, 500 Glowspeed

#5:“Map to Power”, Full Power, Min 5, 600 Glowspeed

#6:“Map to Power”, Full Power, Min 5, 700 Glowspeed

#7:“Map to Power”, Full Power, Min 5, 800 Glowspeed

#8:“Map to Power”, Full Power, Min 5, 900 Glowspeed

#9:“Map to Power”, Full Power, Min 5, 1000 Glowspeed

You may not see in the pictures, but these photo “engraves” have depth. Well, a positive relief, anyway.

She is going to take them all and actually fire them to a cone 6 and see if they change at all. This is more to verify if they were actually fully vitrified by the laser. I’ll report back when she has the results.