We’re teaching a course on letterpress and laser cutting next Saturday, Nov. 11, at SVC in Seattle, and will have a Glowforge on hand. We’ve been testing a lot and have learned so much about the finer points of engraving for letterpress. Now we need to test more actual printing!

That sounds like a really interesting course, if I was local I would totally go!

It would be great if you could put that online somehow, or bring the highlights to the forum maybe. I’d love to go.

I hope you can share a few tips and tricks to people here that wouldn’t be able to see this in person. I will probably want to do some letterpress boxes at some point and leveraging the GF definitely seems like the smart route to take.

Would LOVE to attend an online version of this! Your engravings look marvelous, by the way.

Lots of YouTube videos please.

Dang it. I’m going to be in Seattle on the 9th and 10th. I wish I would have known about this beforehand.

@glenn Wow that looks amazing! (the class) If I brought my glowforge, could I take the class without the tuition fee?

FYI to those interested in going. The cost is $245. I’m not sure why that wasn’t included in the original post.

Oh, I wasn’t promoting it—it’s in Seattle, and I doubt many people on this forum are! I didn’t include a link because I thought that would be inappropriate promotion.

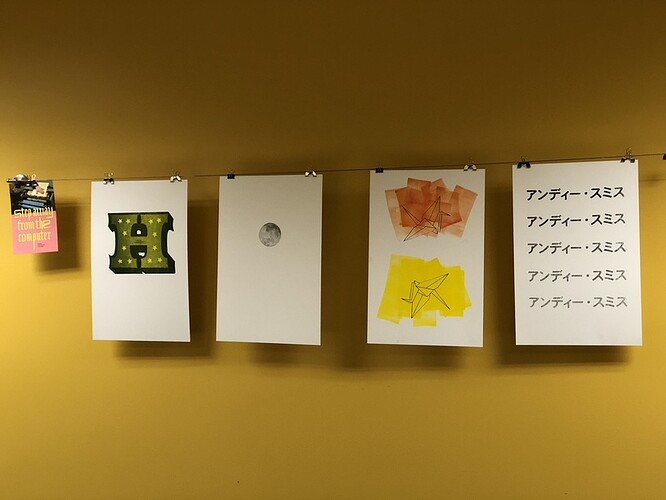

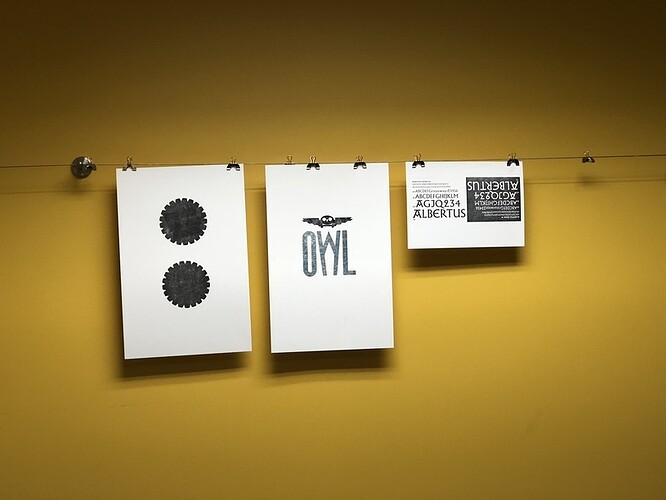

Just wanted to show some of the stuff we’re testing for class and will post more photos after we run the class and have made prints!

Nice idea, but we’ll have one on loan for the class, and the dollars cover the overhead of the school.

Absolutely!

aw too bad. I was hoping have another laser on hand would be worth it to you all

I just went to a local woodworking supply store in Seattle that also has shop hours (at $40/hour), where you can work with a master woodworker who will cut stuff for and with you. (I originally thought he’d teach me how to carry out some tasks and oversee me, which was also interesting.)

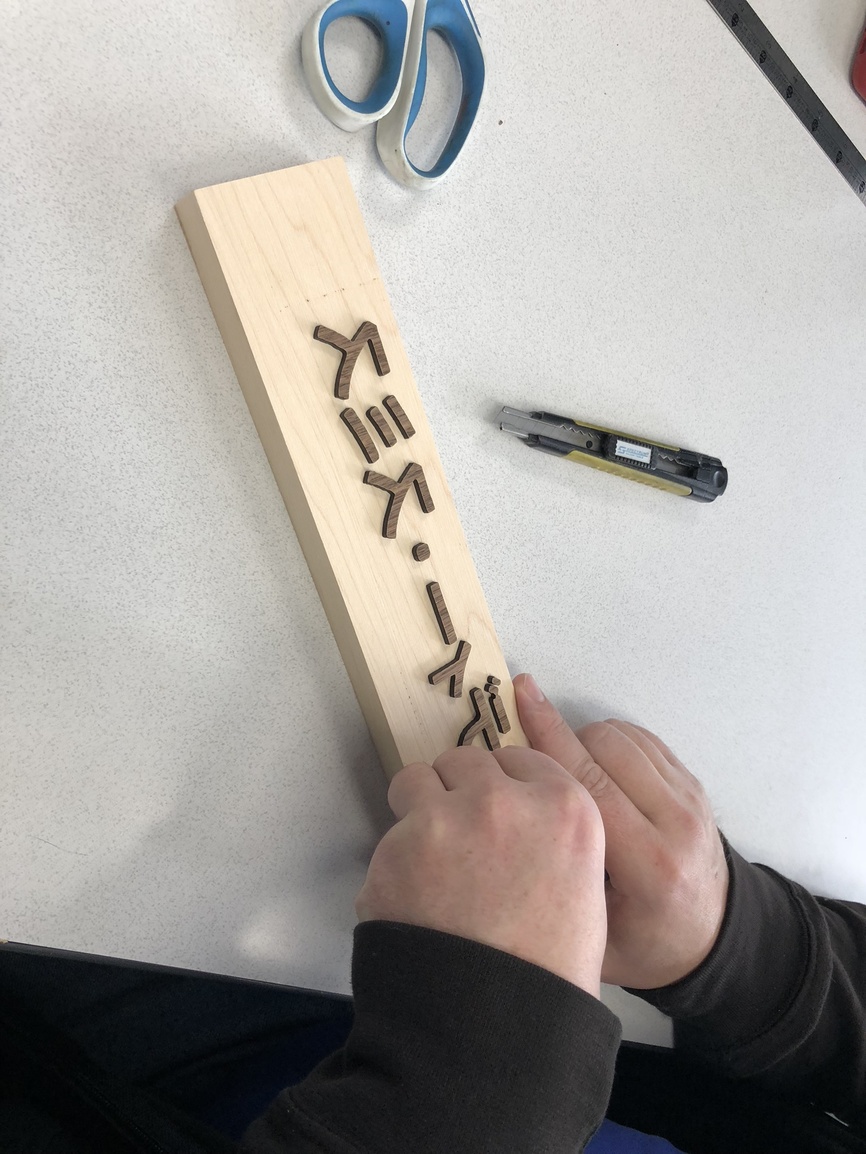

I had him cut some pieces of 13/16th-inch boards down to sizes that work on press and then he used a drum sander to gradually bring the wood to just below 0.793 inches so that I could pair with 1/8th inch (.125) Proofgrade or other plywood to bring to type high. Part of my experiments in figuring out how best to pair Glowforge-cut material with a base to use it for printing.

drum sanders just make me happy. I miss the dual drum industrial one at my old work place. able to sand the finish, but leave the veneer… Best 500$ i spent for a similar one above.

My wife @martinell.jan will be there! She cancelled another letterpress class she had signed up for so that she could go to this one!

OOooo, exciting. I am bringing back photos and more knowledge from the Wayzgoose at the Hamilton Wood Type & Printing Museum, its annual shindig. Much discussion was had about 2D lasers, 3D printing, and CNC routing. They have working pantographs for making wood type from templates, but the templates are very hard to make. The pantograph isn’t easy, but the old craftspeople passed down some of their knowledge to volunteers, who will train others. The templates, however, they’re shifting to CNC cutting. It gets a better result for the amount of time required, and doesn’t reduce the craft portion off it.

Meanwhile, a lot of different people have been experimenting with or doing production design work with laser cutters and CNC. Virgin Wood Type was there, as was Moore Wood Type; Dafi Kühne, a designer from Switzerland who is doing remarkable digitally driven letterpress, and Brad Vetter, who has made his career on top of mixing letterpress and cutting.

Old-school laser cutting:

Looks like it!