semi-relevant anecdotal evidence on the subject, jimmy diResta has a sponsored full spectrum MUSE laser (BOOOOO ![]() ) and on a recent video https://youtu.be/Rjw8Fr0uJm0?t=328 he mentions that the glass shattered because of the cold temperatures… he doesn’t say if it was running… or if he was hitting it with his ice picks!

) and on a recent video https://youtu.be/Rjw8Fr0uJm0?t=328 he mentions that the glass shattered because of the cold temperatures… he doesn’t say if it was running… or if he was hitting it with his ice picks!

Friend of mine belongs to a maker space and they had an epilogue connected to the wall with exhaust tube, and there’s a check valve on that tube leading outside to the cold winter. The members in the maker space thought they could improve the efficiency of the machine by propping the check valve open. Of course they forgot to close the check valve when they finished using the machine and so the cold weather came up the tube, froze the coolant and cracked the laser.

We don’t know what antifreeze is in the GF. But I know my friends epilogue was just water

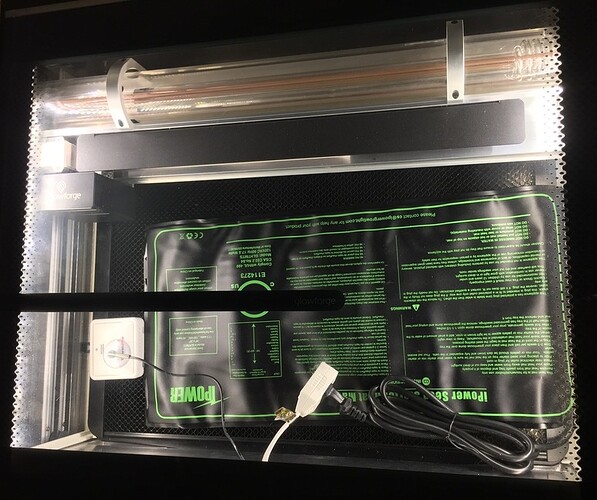

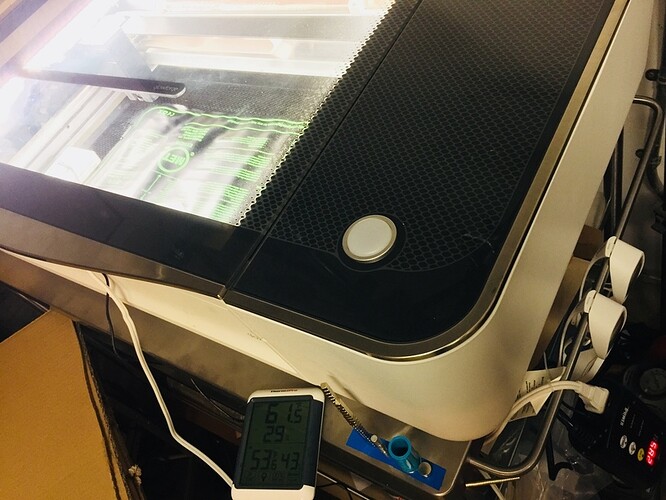

Today is a warm day, but wanted to post pictures of my GF warmer. It’s been keeping my GF at 60F as my garage fluctuates between 40-60F last couple weeks.

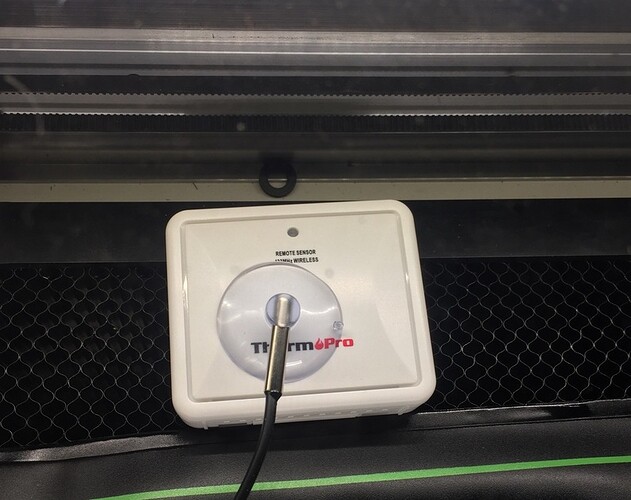

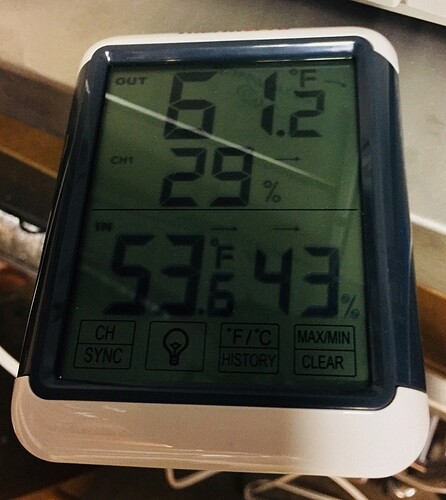

The temperature sensor has an “outdoor sensor” (white box inside the GF) that I simply stick inside my GF. So you can see both the garage temp and the interior GF temp shown on the LCD

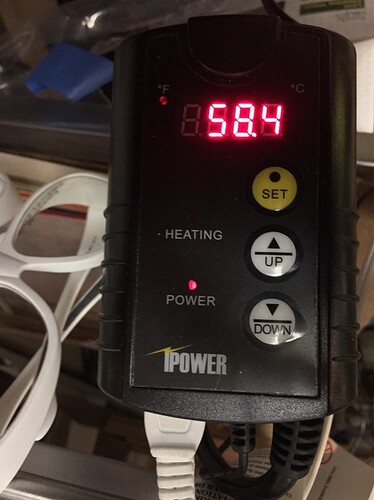

The black Box regulates power to the heat pad with temperature sensor on the suction cup inside the GF.

This is the heat pad:

iPower 10" x 20.5" Small Warm Hydroponic Seedling Heat Mat and 68-108°F Digital Thermostat Control Combo Set for Seed Germination https://www.amazon.com/dp/B01IDQD32Y/ref=cm_sw_r_cp_api_rlvvAb3A4Q7GY

The true test will come when temps get back down to -9F … some day.

According to Amazon that one will usually ship in 4-5 months(!) ![]()

Might want to spend an extra couple of bucks and get it this week (Prime)

https://www.amazon.com/dp/B016MKY7C8/ref=psdc_14252891_t1_B01IDQD32Y

Took amazon 2 days to ship, when I ordered it. That’s hilarious !

This just came up in tips…

I would be careful with this method of warming up your machine:

1.) your other hardware in the machine: glass / metal / coolant has a lot of mass, and probably more than your crumb tray. I’d expect the mass of your machine to not absorb enough heat, or take too long to reach a 60F temp than you’re patient for.

2.) cold outside air sucked in from the blower fans will quickly undo your hard work of warming the tray.

3.) I’m paranoid of cracking glass due to temp extremes. 40F cold air drawing in because of exhaust fans, and hot laser tube == bad combo.

Loving my seedling / aquarium heating pad - but for me, my heater is for Storage not for Use… I just want to be sure my coolant doesn’t freeze, and that the machine isn’t harmed by bitter temps <40F. During times when my garage is <50F or so, I simply dont use it. If I had jobs or needed to use it, I guess I would have to make a decision to move the machine to another room in the house, but so far we have a mix of cold / warmer days here, so It hasn’t hurt my own productivity. With limited space at home, the garage is a great location 3 seasons of the year for my Forge.  With winter season “on pause”.

With winter season “on pause”.

YMMV, but I agree with you in principle.

However, being away from my forge at the moment I can’t check, but I suspect that the surface of the tube doesn’t get hot, as it’s got a pretty good vacuum inside it.

I may well be wrong, perhaps someone could check. but I also suspect that the tube is borosilicate glass, well capable of standing these sort of temperature shocks.

It might even be quartz !

![]()

Agreed, but I’ve heard of people’s tubes cracking. Though maybe those were mounted too tight or some other imperfection/flaw. So it’d be the outer tube that might crack if any, then… not sure how thermally insulated it is from the inner tube, I’m no glass-tube laser expert

Me neither, but it’s a good point to discuss, I think.

John

I’ve had them break when the coolant pump failed and it overheated and I’ve had them break when the coolant froze (sub-zero temps in the garage).

Was either case a GF, or other laser ?

Both were other lasers. Part of why I bought the GF - the embedded sensors and interlocks prevent the overheating problem by shutting it down when it’s too hot (& I believe if the coolant leaks or pump fails I think).

I was initially worried about the cold during shipping causing the coolant in the GF to freeze but I know it didn’t break on me at -9F. I wouldn’t run it in a really cold room (like my garage) because I’m a fragile flower ![]() I hated working in the garage with my other laser. The basement is 60ish and even that is uncomfortable when sitting for hours working on a design. I’ll end up moving it upstairs for a/c in the summer so I’ll have also be comfy in the winter. I waited until my wife suggested it

I hated working in the garage with my other laser. The basement is 60ish and even that is uncomfortable when sitting for hours working on a design. I’ll end up moving it upstairs for a/c in the summer so I’ll have also be comfy in the winter. I waited until my wife suggested it ![]() I just couldn’t put an industrial looking laser inside - those are garage tools according to her. The GF is not only an inside tool but an inside upstairs one

I just couldn’t put an industrial looking laser inside - those are garage tools according to her. The GF is not only an inside tool but an inside upstairs one ![]()

Similar reaction from SWMBO here, so until the filter arrives, it’s the garage for me.

I’m thinking in terms of a small enclosure around the GF and me, perhaps just plastic film over small section timber frame.

I’m waiting on the filter too but she’s okay with the vent. The GF looks like an indoor appliance. K40s and Redsails and when I showed her a Trotec all “looked” like garage machines

The tube is a marvel of glasswork to me. There is the inner tube for the beam, then a water jacket to cool it, then the ‘gas’ outer tube. That little spiral in the outer tube connects the inside laser tube to the outer ‘gas’ tube.

It would be interesting to see how they are made.

Thanks for that Rick. At a glance, the workers glasses didn’t look all that comprehensive considering the potential for exposure in there.

The relatively narrow acceptable temperature range is why I opted to locate my GF Pro in the upstairs loft area rather in the 3rd car garage workshop. And though I have an ugly vent set-up out a window (until the filter comes), I am glad I put it in the house, because I can easily run up the stairs to check on things at night when a job is in progress. (I don’t 100% babysit.)

There are digital thermostatic controllers that you can attach to a heating pad. You can specify the temperature and it will turn the heating pad off/on to maintain a temp.

We have a refrigerator in the garage my husband uses for brewing beer. He has a heating pad attached to the wall of the fridge. The fridge turns on and off, and the heating pad turns on and off to maintain a consistent temp in there.