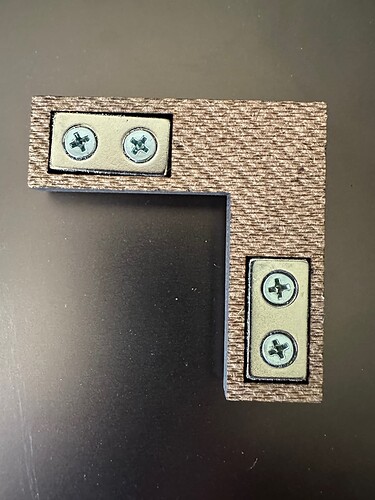

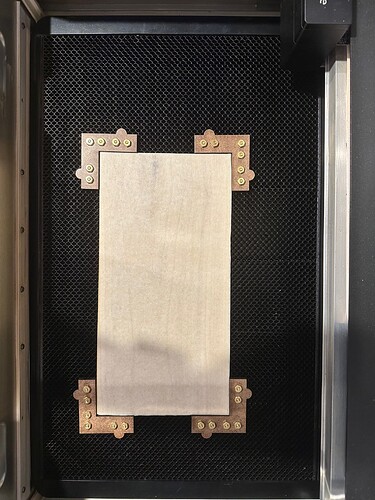

Hi - I needed something to help hold rectangular pieces in registration on the crumb tray. I have a good handful of 1" x 0.5" rectangular Neodymium magnets in my shop. I designed these corner brackets in Adobe Illustrator, and cut them from 1/8" tempered hardboard. The SVG file is attached to this post, feel free to use it if it helps you out. This could easily be modified for other magnets if desired. I designed these to be two layers so If I want to use them with really thin stock it would still work out, but if you don’t have a need to work with stock thinner than 3/16" feel free to leave the lower support off. The magnets were attached with brass screws and nuts and the two layers of tempered were glued with with thick crazy glue. The magnets were attached with 3/8" long 6-32 brass machine screws and nuts.

Those look lovely - and reliable!

Do be careful that if the magnetic field can be felt on the top side of those and your head/air assist fan goes over it, you will frequently get a fan error. If you put even a thin piece of metal on the top side that’s usually enough to stop the magnetic field!

Also, if very exact registration is important to you - there’s a boot you can make that’ll make sure your crumb tray doesn’t wiggle in its divots ![]()

I’ve been using these for a bit and they seem to work fine with no error’s from the air assist fan. Since these rest on the crumb tray the magnets are still pretty far away from laser head/ air assist assembly. I’ve been using other magnetic hold downs on top of work for a while with no errors from those either. Thanks for the tip about the tray boot holders!

It took me a year to discover almost all the issues I was having were due to neomagnets. One of the first things seen is that the cut does not go through, but only in localized areas. If you watch, you occasionaly see little candle like flames. If then you go back, those areas with the candle type flames will not have cut through.

The easiest test is to hold a screwdriver loosely at the height of the bottom of the carriage and if you can feel the downward tug the magnet is too much. I have found that small magnets ~1/8" have very short fields and several of them arrayed will have no effect on the electronics (unless one gets loose and messes with the fan/electronics until you find and remove it.) Your idea would work well with these smaller magnets glued firmly in place.

I did put a paper thin sheet of steel on my inch square neomagnet, and it did reduce the field considerably, but I could still detect it so I did not go there. It is possible your steel screws and nuts lessen the field above, if so that would be a good thing to know.

Round shielded magnets with 1/16" thick steel shells are decent also but the screwdriver test is still warranted.

Keep in mind here the laser head is not do any cutting over the area of the magnet. Those are used well outside of the cutting area. They are simply used to constrain the item you cutting from moving during the cut. Even if the field was strong enough to interferre if cutting directly over the item, they are never used that way - at least the way I am using them.

Thanks for voicing the concern - They work really well in my application - YMMV!

Evan

The area of concern is under the fan, several inches behind the cutting head. But whatever. It is interesting if the metal screw eats the magnetic field, I will want to experiment there.

I would also suggest a layer of hardwood on top, if that wouldn’t make it too thick, as a precaution against accidentally lasering the screw heads.

There would be a lot more damage done to the hardwood than the screw heads I think?

i meant, to avoid any damage to the GF from reflections off metal? Or is that not a concern?

Not generally a concern. Infared is weird for those who think in visible colors. Copper is extremely reflective while other metals less so. More importantly is focus and the scattering would be considerable.

I like how you created tabs to help lift the magnets off the bed; they could also be used as hold-downs for another shape to be cut. I hate chasing magnets around the honeycomb–then when I capture them they won’t let go.

Thanks Kelley! (Secret - this is the 2nd generation. 1st pass didn’t have them and I added them in the 2nd generation to help grab them to lift them up).

Evan

Those look like they mean business! Wouldn’t two corners suffice, or even one in a pinch?

Absolutely - two would be sufficent. I made a set of 4 as a ‘just in case’, plus I have a good size handful of the magnets on hand. They do work very well!

How strong are the magnets? Is it hard to remove?

They are pretty strong. Thats why I added the little circular tabs, so there is something to grab onto.

Evan