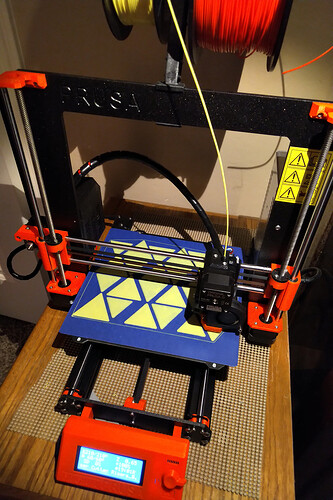

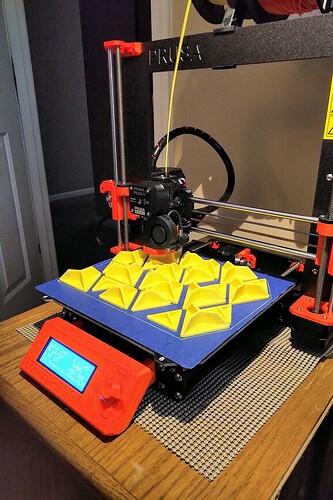

These are nice. I use calibration cubes sometimes for making up the height. I have several sizes so I can easily put in 1/2" ones or 3/4" ones. I wish I had started out in metric with the Glowforge. I haven’t yet switched my designs and materials thinking over, but for heights and leveling, it is so much easier.

I’ve spend a day fighting with my CR-10s. I decided to try and flash a new firmware. Easy they say. Well, there are some steps left out of the process and I ended up trying several different versions before finally reverting back to a stock Creality offering. Then I was getting max temp errors. Eventually I traced it down to the SD card that I had left in the control box. Something gets messed up. When I rebooted everything without the card in, finally it seems to work correctly without errors in Octoprint.

I’m kind of miffed too. I had a bunch of projects I wanted to get going on. And then my shipment of filament for the holidays didn’t come in. Arg. So ranting away.

I think I am back up and running but only have pink, ivory and grey filament at the moment and that not much of.

Very nice … I already made some risers … but, this would also have worked.

Hi there, I don’t understand the purpose of these

how will these help with lasering thicker materials?

isn’t there a 2" max material thickness as is?

if you’re lasering 1" thick material, will these risers help, bringing the material 1" closer to the laser head?

thank you!

Exactly. You need to get the material into the “envelope”. So a 1/2” riser with 1” material would put it at 1.5”, which should be about +.13” above the “zero point”.