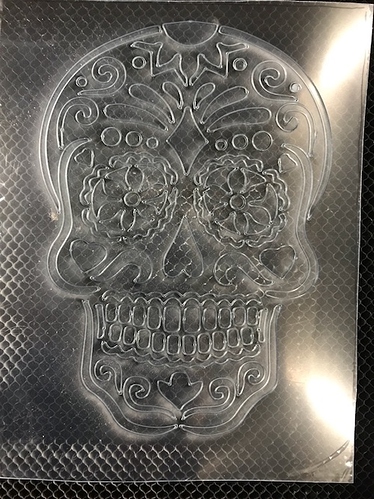

How pretty!

Thank you  I have been trying to cut stencils for the last 3 weeks with no success that I decided today it’s time I give that one up for the moment and make something else! (No matter what setting and thickness of Mylar I use, there were burn marks. )

I have been trying to cut stencils for the last 3 weeks with no success that I decided today it’s time I give that one up for the moment and make something else! (No matter what setting and thickness of Mylar I use, there were burn marks. )

I’ve never tried Mylar - that’s pretty thin. Are you sticking a masking tape on it to stabilize it?

@Jules - i tried cutting 7.5 mil frosted Mylar with and without masking tape. made no difference. ugly singe/burn marks. then i tried 5 mil Dura-lar (since I saw someone here say they’ve had success cutting it)…used the same setting as they used but got the same result + the 5 mil was too thin for what I need the stencils for.

I once took a class about silk screening on ceramics.Using a flat silkscreen on a round concave piece (like a bowl) seemed impossible, but what we did was silkscreen soft paper and lay that on the pottery, and when done very carefully could do amazing detail.

Thus using silkscreen or flat stencil you can still apply it to curves. Of course if it is a one off you could use heavy paper or even just the masking paper with the backing still on it.!

What speed and power are you using? If you are getting too much burn, you can knock the power down or speed it up.

@Jules - for the 7.5 mil, I used 500/70. Then I tried 500/30 – it didn’t cut all the way through. I played with many other combinations (400/30; 500/50; 450/20, name it…) with and without masking on the Mylar. I’ve done like over 25 cuts and not one has come out acceptable. With the 5 mil Dura-Lar, I tried the 500/30 (the setting I saw here on the forum that someone used)…it didn’t completely cut through + there were singe marks. The main reason I bought the Glowforge is so that I can laser cut the stencils I sell so I can speed up the process of cutting…I have outgrown my two electronic cutting machines and I’m ready to graduate from using blades and sticky mats!

You’ll get better results with something as thin as mylar if you keep using a sticky mat…I know they pretty much suck (used them for years) but thin materials can get blown around by the air assist with a laser, ruining the cut.

I make my own with the Krylon 7020 and a sheet of scrap plywood.

I’d try using 500/20 with two passes. (You can set the number of passes down at the bottom of the Manual settings.) Maybe mylar requires a delicate hand…sounds like it. Some materials are like that.

It is looking like I may have to stick to my 2 machines for cutting stencils and use Glowforge for my other products. However, I have one more stencil material to try before I give up on laser cut stencils.

Oh and I did try using 500/20 with 2 passes…and also 500/10 with 3 passes. Those produced the ugliest results. Despite multiple passes, the laser didn’t cut all the way through…just made an even uglier mess of the cut edges. I also tried focus heights of 0.01 and 0.02.

Hmmmm. I’m currently cutting 7.5 mil Mylar stencil material at speed 300 and power 25. Maybe give that a try?

Oh, and your coaster is gorgeous! I’d be itching to color it in with Prismacolor pencils, but that’s just me.

I’ve had success using thin acrylic to create stencils. I believe this is what I buy (I pick it up in person): Plexiglass Sheets in Clear 0.030" X 24" X 48" Impact Modified Acrylic Sheet

It’s bendy, but not as thin as other materials. I’ve found it works well with chalks, sprays, and pens. Here is something I made for an event at my college. It was a quick chalking job, but it shows it works.

This also worked well:

Good luck with stencils! They’re super fun.

oilboard won’t last as long as mylar, but it’s pretty great for stencils.

I suppose when you stop by they ask “what’s you poison?”