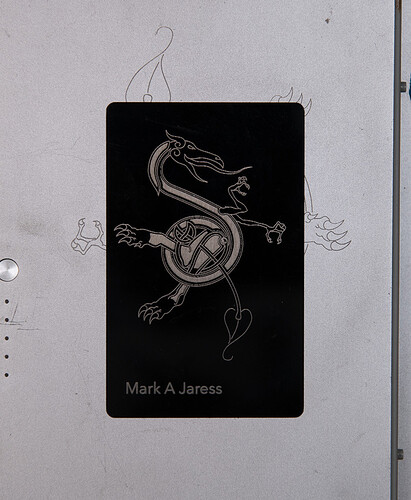

I spent about a month figuring out how to engrave a design on to metal. I started easy - engraving first on to a small piece of anodized aluminium, which was so easy. I then tried to do the same to a piece of steel. That didn’t work out so well. I then tested several types of coatings on the steel, as I learned you need to drive something into the metal with the heat of the laser. I tried mustard and vinegar, I bought a can of Molybdenum lubricant, which worked wonderfully, and, finally, I bought a can of Cermark spray, which is designed specifically to help engrave on metal. This worked extremely well, so, I thought I’d try the Cermark on an old MacBook I had lying around. Here’s the result

Sweeet!

Any shots of the laptop without paper?

I thought Mac Books were already made of anodized aluminum, which should engrave without the use of Cermark. Is that not the case?

Cermark and Molybdenum just drive carbon into the metal, so you get a great black outline - the Moly creates a lighter look while the Cermark create a very black impression. My first tests on Aluminium did great, but, without color (a silver look). I’m told, over time, the silver look will develop a patina of some color, but, hey, I just love the look of a solid, stark black line.

The coating isn’t paper, it’s a spray called Cermark, which is designed specifically for coating metal for laser etching. It drives Carbon atoms into the metal, giving the etched area blackness.

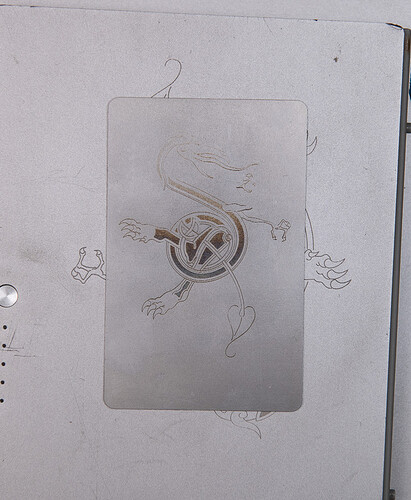

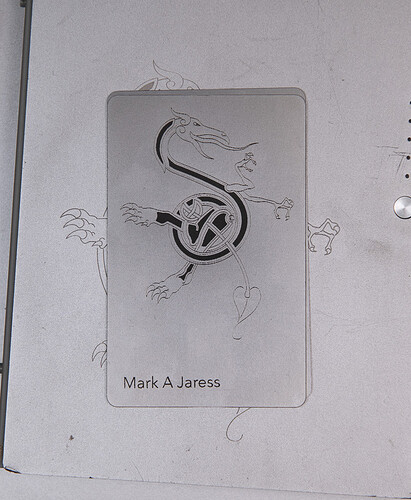

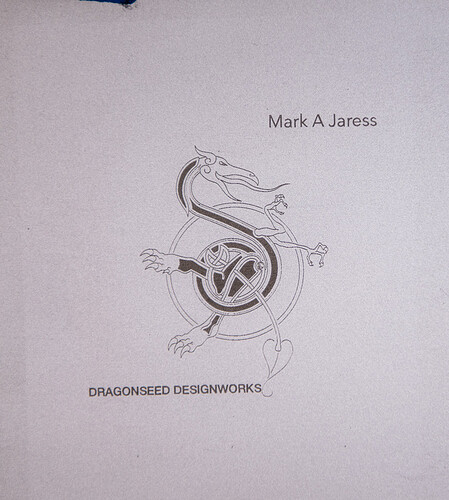

This is my first attempt at etching an old MacBook. When I did this, there was no color to the etching, it was just a brighter silver color. It sat on a shelf for about two months, and I hadn’t even looked at it until today. I guess the aluminium corroded into the nice grey patina it has today. I wonder if the patina will deepen even more over time?

The second attempt at etching aluminium was on black anodized aluminium, and it just burned off the anodization. Black on silver looks pretty good. I wonder, will the exposed aluminium develop a patina like on my first test, over time?

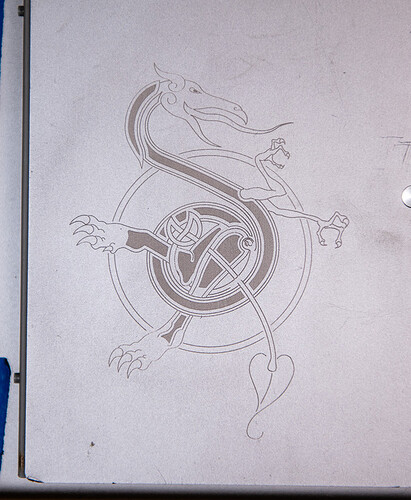

I did some research on the Internet, and, on the advice of the Hive Mind, I bought a spray can of molybdenum to coat the steel. The etching looks really good. It has light and delicate lines. It was a real bear getting the molybdenum off, though. I had alcohol at home, but it wasn’t the right kind, so, I bought a pint of Denatured Alcohol, which did the job. Wear surgical gloves when you clean the metal after etching, though, this stuff gets everywhere and you’ll have grey hands if you don’t

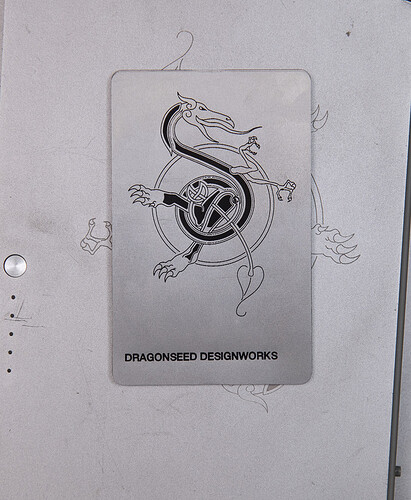

Encouraged by the success of etching steel with molybdenum, and watching a few videos of etching with Cermark, it looked like the Cermark etched even blacker than the molybdenum, so I sprung for a spray can of Cermark. It is expensive, but, people are claiming . they profit about $5k in services from one can. The etching came out beautifully, and, yes, it is a blacker and heavier line, but, I’m pretty happy with the results.

You’ll notice that the steel is a little bit warped by the laser - I think I set my settings too hot or the scanning too slow, which heated up the steel enough to warp it slightly

One of the really nice things about the Cermark is that it comes off by wiping it with a damp cloth, or, in my case, a couple of dampened paper towels. I felt I could control the removal pretty well, without risking getting the innards of the MacBook wet.

These last two are the final on the old MacBook, using Cermark to blacken the etching. It just so happened that the guys at Glowforge released a preset for MacBook anodized ALuminium just a day or two before I was getting ready to do this experiment, and that was the settings I used for this test.

Nice comparisons of all the methods! I like that Cermark. (But am too cheap to buy it.)

I agree - unless you’re going to offer services etching metal and want the darker etched lines that Cermark gives, it isn’t worth it. If you do offer such a service commercially, I think it would be a great investment, with a phenomenal ROI

Which type of Cermark did you use? They have Aerosol Marking Spray and a Marking Paste type, I’d almost think that paste would go a long way compared to aerosol, but I could be completely wrong (it happens from time to time, just ask my wife).

I got the spray can. From estimations made by others, a $100 can of spray translates to around $5000± a few bucks. That and the ease of use were the clinchers for me. I also experimented with Dry Molly, which works very well. except you need to use alcohol to clean it, which is a bit more difficult and messy. The two make different colored etchings - the Cermark leaves a very black mark while the Molly is a lighter grey. My thoughts on that are that this difference can be exploited if you want to incorporate the two in a “bi-color” design. I’ll experiment with that in time, if I can think of a design where that will look good in and I get the time.

I’m not at the point of offering any services with this yet, maybe some time after the nNew Year, so, we’ll see if this pays off as services offered in the consumer market. (the very few people I show my experiments to say they’d like to get something etched, though).

Ideally I’d love to see if it could etch a slide from a 1911 or the likes, just don’t want to practice on a nice one

Anybody here try this yet?