Hi All

A few weeks ago I posted about a Nespresso pod stand I made with the intent to start designing and selling files.

I was aiming to design something new every week as little challenge for myself. But things got busy and I didn’t get round to do anything for a few weeks, but I did make two new design this week to try and make up for it! (Even if they are very similar)

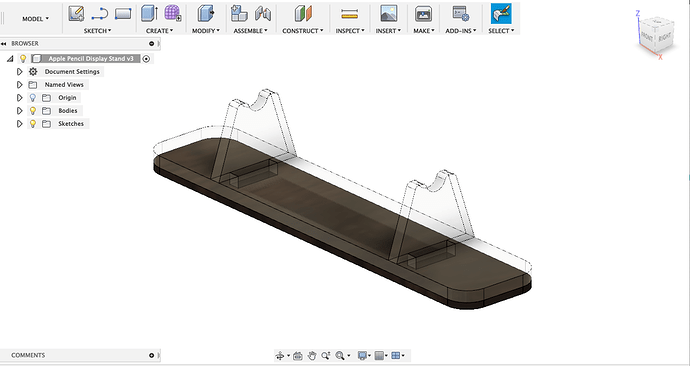

The first was a Apple Pencil stand (other pens also should fit).

I recently got some thicker 5mm clear acrylic and I really like the way it looks compared to 3mm I normally use. I think it add to it and makes it look a bit more premium.

I think having the wood base with the clear base on top, looks really cool.

I am a Product Designer in my day job and find when it comes to making anything that’s going to end up a 3D object its much easier for me to design it in 3D. I use fusion 360.

Its quite simple when you get you head around how the tools work and it very powerful for designing. I definitely recommend learning it if you are interested.

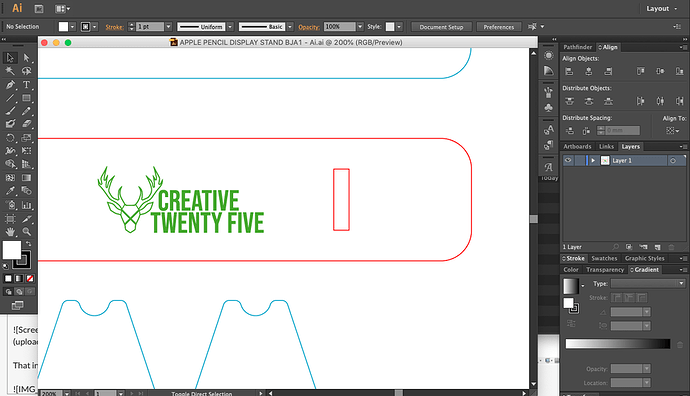

I then export the multiple faces for laser cutting into illustrator where I set up my SVG file and add graphics and things if I want to etch anything like my logo.

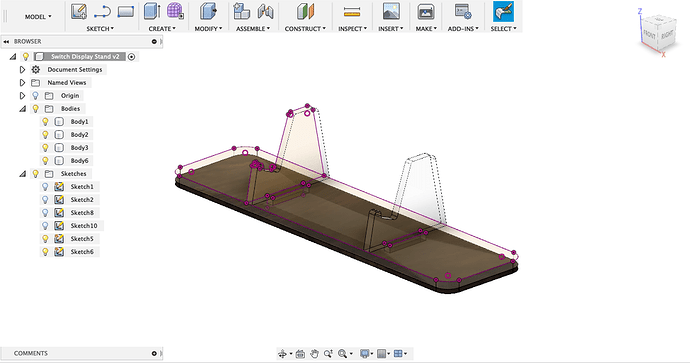

Using Fusion 360 allows me to make quick changes or even modify them to use for more designs. Using the pencil stand I was able to alter the base size and upstands to make a display stand for my switch.

In the real world It looks something like this.

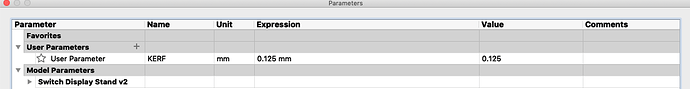

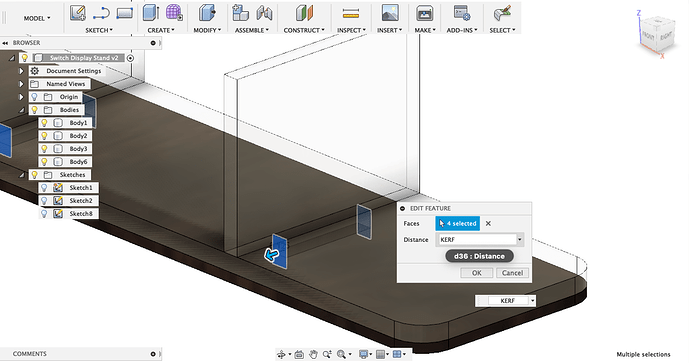

Also a useful feature you can use in Fusion360 is to add expressions to your models (the feature is actually called Parameters in fusion). I use this tool for adding Kerf to my models.

So when I add material to the tabs to account for the lasers kerf, I can off set those faces by my expression “KERF” in the dimension box rather than typing a dimension in each the time where ever in the model I want to add kerf.

This also makes it much easier and faster to make changes in the future if I am wrong or change the material I am using for the design as this may have a different kerf value. All I need to do is just go into the expressions menu and update the kerf value and it will update everywhere in the model where the term “KERF” is used for a dimension.

Do many people use a 3D modeller like Fusion360 to design their laser cutting projects? I’m guessing most people would use 2D software like illustrator to design things but I think I’ve just been trained into thinking in 3D too much.

I was just going to post pictures of my latest design but got a bit carried away with a bit of the write up of my process. Let me know if it helped and maybe if you have anything in particular you want me to talk about I could do another post about fusion 360.

Anyway I hope some people find this post helpful or at least mildly interesting.