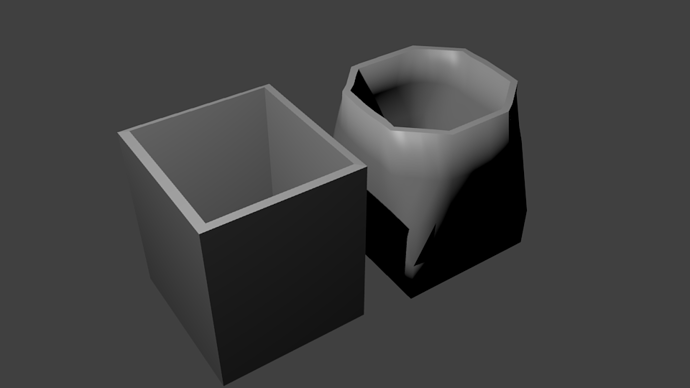

Instead of trying to square the hose, which will slightly decrease the cross section, you could attach something like this flange to the inlet you build.

That gets me just where I do not want to be. It would be easy to make a four inch hole in a ten inch disk and caulk the joint but it would put the dust in a four inch circle clogging the filter at that point and putting more back pressure than the squared off hose.

More complicated would be an octagonal entrance that would minimise the narrowing but be more difficult. Finding the right materials will determine the design to an extant as the longer it takes, the longer it will be before I can do what I want with the Glowforge.

If I understand your octagon idea—which maybe I don’t—you would be attaching to the edge of the octagon, so the airflow would be tangent to an edge…and your connection would be a square opening.

If you make that a 4” square, you could attach the circular flange to it as the interface to the hose.

This is the square to oct I was speaking of, in one case it comes out square, and the other the corners are cut and a triangle fitted to make it octagonal, pardon the crude blender explanation with more thought It could be better

sorry somehow I missed this -Tampa

Thankyou

well, if you ever come to Montreal Canada I’d 3d print a coupler for you!

I think that you want the hose to connect to a true circle. Otherwise it will be difficult to get a good seal.