laughed so hard my stomach hurts

While it won’t bring it to straight/smooth resistance/turbulence levels, the inside will have less square inch/foot exposed than an uncompressed flex tube. It might have a small percentage of less diameter, but with less exposed ridges and creases, air will flow with less resistance and turbulence (like unmaintained dirt irrigation ditches versus dirt ditches that are cleaned out of plants, rocks, garbage and the sides are scrapped “smooth”).

While smooth concrete ditches are optimal, dirt ditches can work well when minimizing resistance/turbulence.

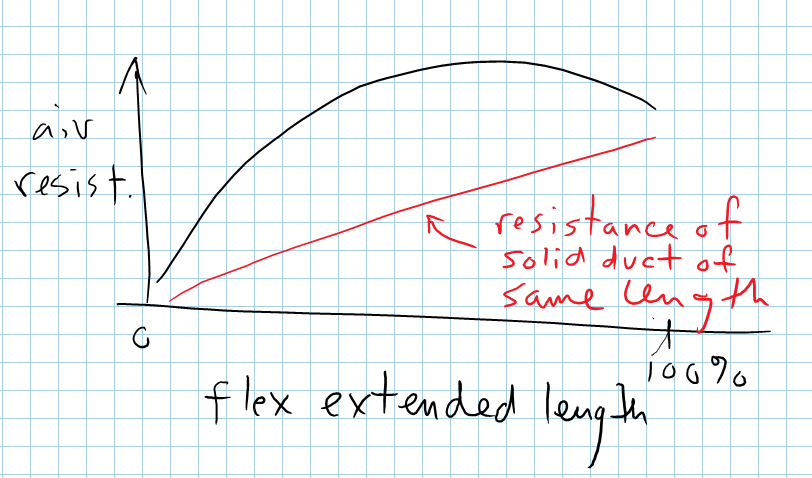

Another interesting question. As the duct is compresses, the resistance goes up, but eventually, the folds come together they may possibly have lower resistance!

We get it, you vape.

Lol, no, actually, I don’t, and never have. I just have a wild imagination at times

+Glowforge = neat stuff! ![]()

Glad I could brighten your day

As @jbv notes:

The simple aluminum foil doesn’t have the strength to draw the flex coils tight enough to “smooth out” the creases and bumps. Otherwise, in theory, you would get smooth wall performance after bolting the GF ![]() to the floor and strengthening the a exhaust ports (on both ends) to attach the tightly stretched flex duct.

to the floor and strengthening the a exhaust ports (on both ends) to attach the tightly stretched flex duct. ![]() (couldn’t find a slinky emoji

(couldn’t find a slinky emoji ![]() )

)

Not exactly the same but for dryers the rule of thumb is that a 90 degree bend adds 5’ to the effective length.

Here is Mechanical Code info for reference:

Dryer Exhaust Duct Fitting Type Equivalent Length

4” radius mitered 45 degree elbow 2 feet 6 inches

4” radius mitered 90 degree elbow 5 feet

6” radius smooth 45 degree elbow 1 foot

6” radius smooth 90 degree elbow 1 foot 9 inches

8” radius smooth 45 degree elbow 1 foot

8” radius smooth 90 degree elbow 1 foot 7 inches

10” radius smooth 45 degree elbow 9 inches

10” radius smooth 90 degree elbow 1 foot 6 inches

The radii listed are the radius of the bend.

These are all for 4" round metal exhaust duct (not flexi-duct).

Excellent info, I’m bookmarking, thanks!

I also have ordered a GF with the filter. Rather than worrying about venting until I get a filter, is it safe to simply run the GF in an open garage or outside under a covered patio?

Dan has asked that we don’t discuss safety in the forum, and to be advised by the manual when it arrives.

If it were me, I would probably just crack the garage door and stick the extended hose out.

Is it a safety issue or a comfort issue?

If the filter unit is a charcoal and HEPA filter, doesn’t that imply that it is more about filtering smoke and smells rather than poisonous gasses?

I don’t know enough about what type of gasses could be created, and when something becomes so noxious that it is dangerous.

I assume that acrylic could get pretty stinky, but would this be dangerous?

Is this part of the reason that the filters are delayed?

Yeah, safety issues - we can’t discuss. I’m going to recommend that you use Google to find a list of “things that should not be lasered”. (And print it out. And keep it handy.)

The filter on the Glowforge is to enable people who can’t vent out a window to run it indoors. It is probably not going to be as effective as venting out a window for keeping smells down.

While the machine is running, being vented out of the window, you can’t smell anything. When it stops running and you open the lid, you get a whiff of whatever.

Leather and some acrylics stink.  Some other acrylics don’t stink as badly. And I like the smell of some woods more than others. (Just personal preference.)

Some other acrylics don’t stink as badly. And I like the smell of some woods more than others. (Just personal preference.)

What you are smelling at that point is the burned residue. It’s not floating around in the air, but it does cling to the masking. Removing the masking promptly and sticking it in a ziploc bag pretty much eliminates the smell. (And keeping the buildup off of the grid. I use a wire brush on it weekly. Just like cleaning a grill.)

As far as the delay on the filters…I’m sure the filters are being developed by a different team, and depending on whether or not they get taken off of that work to work on other projects, might be the reason that there are delays on the filters. No way to know yet.

So you are saying that the ventilation and the filter are more about stinks than about safety.

Similar vein, if something is “laserable” it would also not put off poisonous gas, right?

As in, it might technically be possible to be cut something with a laser but it would also need to be “safe” (no poison smoke) to be considered “laserable”.

I have heard that some woods, like purple heart, have toxic sawdust.

I don’t know if this would apply to the smoke as well.

@dan mentioned that lacewood could cause problems.

Does the fan continue to run for a period of time after the cut, or does it only run while cutting?

No, I’m not saying anything about safety because I’m not allowed to.

That is something you will need to research. Or just stick with the Proofgrade materials at first, until you can see for yourself if any smoke gets into the air when you are lasering. (It doesn’t, if you have it vented. That’s all I can say, because I don’t know what the filter is going to do yet. i don’t have one with this test machine.)

The fan runs long enough to blow all of the smoke out. (Little while afterwards.)

One thing I can say from experience playing with a tiny baby diode laser: it is no fun being in an unventilated space where things are being zapped. Even with items whose smoke is not particularly toxic. If you’re not filtering, venting of some kind is pretty non-optional.

Here is previous forum information, for some interesting reading.

And Google is your friend.

Just a thought, what about a fine water mist outside of the exhaust outlet to capture whatever makes it out. Understanding that the water may end up dripping toxins on the ground nearby and noting that it would not work well for those in the north (freezing).

Might work well for those in close proximity to the neighbors.