This is going to seem really stupid but how bad is plastic with chlorine to laser? I will never purposely use it obviously and I know it’s bad to breathe in (yay for nerve gas…) but how long will it take for it to ruin your machine? (eg. 20 second of use or like months of use)

If that makes any sense what-so-ever. Ha-ha.

I wonder if something could be added to react with the chlorine to absorb it / remove it before it does any damage.

The biggest problem is that the chlorine released mixes readily with any water vapor in the air, and creates hydrochloric acid, which then happily dissolves the lenses, the filters, your eyes, etc…

I am not sure that you will ever get an answer to this that is other than a guess. Unless someone is willing to step forward and say “yeah I cut a bunch of PVC and destroyed my machine in a week”…

The reaction releases HCl which is a highly toxic and corrosive. It reacts (dissolves into) water to form Hydrochloric (AKA Muriatic) acid. This has the ability to corrode steel just by looking at it. Much of the innards of a machine like a Glowforge (note my careful wording  ) are going to be made of steel. There are lots of other substances that HCl will attack as well, so the steel problem is just the beginning.

) are going to be made of steel. There are lots of other substances that HCl will attack as well, so the steel problem is just the beginning.

Just don’t. You don’t really want to be the guy who conclusively answers this question, do you?

Haha, Thanks guys for the answers. I pray that it will never happen to any of us. Haha.

I have heard people report they do cut chlorinated things, and just perform a lot more maintenance than usual.

Doing a quick search, I find these two interesting threads:

Throw away their machines every few months

So… it is nasty. In small amounts it means rusting things which shouldn’t rust. There will be residue and people will always know what you did the moment they open your device.

Compound the chlorine effects with the plastic shell of the GlowForge and you are likely not looking at a few oddly rusted screws, but rather weak spots and eventually holes through your shell.

Small occasional bits of chlorinated materials are probably still permissible. But doing it too often is likely far worse in a Glowforge than in any other laser cutter out there.

Oh, and all of the people who said they do go ahead and accept the machine degradation and cut chlorinated materials anyway always stressed that their exhaust had chemical scrubbers.

Wow. Great resources. Thank you. I will be avoiding it like the plague!

I feel like this question is more about if you put something in the forge that you thought was safe, but isn’t, either through poor research or a mislabeled product/material.

I ordered two different mylar sheet products off of amazon to make stencils from. On arrival, one of them says “mylar-stencil roll material” on the packaging. The other just says “plastic sheets.”

I would like to trust that it is also mylar… but just looking at it i certainly can’t tell, and I don’t totally trust my own personal results with a copper-wire burn test.

So…

Would it look different as the laser hits the material, to the operator watching through the glass?

And if so, how much time would you have to stop the GF and (attempt to) clean out the innards before irreparable damage was done. No time at all? A minute or two? Is there anything that would slow or neutralize the effects of the chlorine?

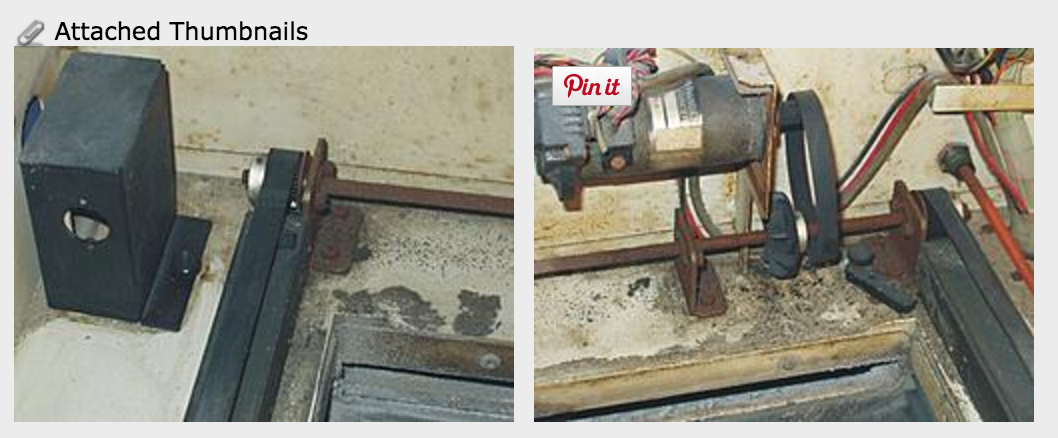

The second page in the second linked thread has pictures which look like they are straight out of a junkyard. Supposedly a machine that ran PVC cutting for only 3 days.

If there is anything visually distinctive, you are already too late. A plume of yellowish smoke would be a clear indication of chlorine gas release, and a lot of it. In the linked threads earlier someone said they saw that, and opened the machine to find a newly liquefied lens.

In most cases, you would be releasing small quantities and not able to tell much of a difference (I imagine).

I missed that post of yours while I was typing my response…

wow, that photo of the corroded interior looks like it had been left outside for an entire winter!

Its soooo intense. Almost hard to believe.

I know companies that cut vinyl with the laser…

I’ve cut vinyl in my laser… Its not going to eat your laser immediately. Before anyone reacts…please continue reading to the end…

Cutting vinyl and PVC creates chlorine gas which in turn mixes with water content from the air and becomes HCL (hydrocloric acid)

As it is corrosive to acrylics and glass, if left on for long periods of time, it can scar and make these components brittle and crack. So mirrors, lenses and the see through lid are not safe.

…that being said…as long as you wipe down all surfaces you wont really damage the components of the laser if you dont do it often. Rubber and many plastics are not really affected from what I understand. HCL is stored in plastic bottles after all.

—This is the big issue with lasering Chlorine based products—

Once the gas is released, it is very bad for the human body or any flesh for that matter…ie pets etc.

In humid environments it mixes with water and collects on what ever you cut so when you pick it up or handle it…it CAN cause burns.

The gas continues to be released from vinyl or PVC for up to an hour or more after its cut. Even with really good ventilation, the HCL can collect in your ducting and slowly corrode…hard to wash those out…

Chlorine gas will damage eyes, lungs, mucus membranes, skin etc. You can’t grow those back so thats mostly why its unsafe to cut vinyl and PVC.

Unless you want to throw away your GF and risk poisoning yourself, don’t do it, brother. I’ve seen pictures of lasers turned into solid rust buckets from not too many pvc cuttings.

Before we knew about the effects, my dad’s tools rusted to hell from being stored in the garage next to the SEALED bucket of pool chlorine tablets.

You have the benefit of real world experience, and I believe it worked for you.

Some time ago I started to compute how much chlorine would be released when cutting PVC. At first it seemed like not that much, and I was thinking “eh whats the big deal”. Then it was pointed out to me that I had gotten the calculations wrong, and that the amount was at least 3 times what I initially thought. I will not be cutting any PVC.

As an aside, I have a bottle of fairly concentrated HCl sitting on a shelf, I use it to put a nice rusty patina on steel. It works really well for that, and I can only imagine what it would do to the insides of the lovely machine sitting in my office. As far as I am concerned, you would be hard pressed to clean this thing well enough to recover from that.

And the lenses are NOT glass. They can’t be in order to pass light at the frequency a CO2 laser uses.

My intent is not to scare anybody - Don’t Panic. The reality is you can never 100% trust your suppliers. Some of the raw materials we use where I work have to have certificates from their suppliers stating they meet certain specifications. Every once in a rare while the material has the cert, but they don’t meet the spec for one reason or another. These are industrial manufacturers/suppliers of high grade materials that have existed for decades and have been supplying said certs for about as long. Your general suppliers, whether it be ebay, Amazon, alibaba or Home Depot are going to have varying degrees of control, but none of them are probably used to being worried about “laser safe.” A plastic sheet with a 3M label or Dow or other big company name on it is far more likely to be what it says, but there are no guarantees.

So that leads me to my point: be prepared (have a vague idea what you would do) to get something you don’t expect. That doesn’t necessarily mean chlorine it could be anything. And that something could be, “last time it cut, this time it melted,” or “I don’t remember it smelling like musk ox barf in here” or it could be dangerous as in, “wow did you see that flame?” Dan and company have already designed in some safety features but the universe will win if it really wants to. So, Don’t Panic; balance the pros and cons of buying from different vendors; have a generic contingency plan. A laser is just another power tool and needs to be treated like one.

This is the image @jacobturner is referring to. The person who submitted said it was after 50 hours of cutting PVC.

Just to clarify, when I posted my opinion on cutting PVC, I failed to say that it is not recommended to do a lot obviously. I’m just saying if you accidentally cut a piece or two it’s not going to immediately destroy your machine.

Excellent advice. I plan to keep a logbook detailing each cut, settings, materials, etc. like the one I keep on my smoker. (That logbook sure comes in handy when it comes to ribs-smoking time!–no reinventing the wheel.). I’ll put the decal @JBV is sending me on the cover.

The more humidity, the more pronounced the action.

Dry here in Colorado, but remember that rusty steel I showed you? Cleaned that to the bone with muriatic acid, which is a dilute solution of hydrochloric (20-30%) in a pan, left it overnight.

The next morning, the steel table I had it on (under power ventilation) had a layer of rust all over it, and so did every bit of ferrous metal in the area. Those fumes just wafted by on their way out. It’s pretty dramatic. Cumulatively, I know it will eat a machine in any and every way it can.