Tormach has recently released a new desktop mill, they call it a router. $2995 with their dedicated fancy oooooohh-la-la!! controller.

Even comes with a FREE t-shirt. Wish I had gotten a Glowforge shirt.

Pretty small work area.

Pretty cute, I like the esd button.

I do not need this. I should not buy this. I’m having trouble resisting.

i just forwarded the link to the model shop group in my office. it’s probably borderline too small of a working area. but we could potentially mill multiple pieces and glue them together. and this would fit nicely in the new configuration we’re working on that moves the laser cutter out of the small model shop room into the print shop (which the model shop room is enclosed inside of) and turning that model shop room into a “dirty” room (where we’ll add a saw (band or scroll) and sanding capabilities. which isn’t big, so this would fit nicely on a counter.

Stop, just stop! I don’t need this…! I wonder how loud it is? Could I make room for it in the lair? Free t shirt? Damn you!

It’s just too light on specs and information at the moment. I guess they’re targeting the EDU market, where administrators will be buying it to equip school makerspaces without really caring about the tech specs. I think I’m safe for now, I have the X-carve and the Shaper Origin already, so this probably wouldn’t add any new capabilities.

If a bunch of YouTubers I watch start showing these off, though, I’m probably screwed.

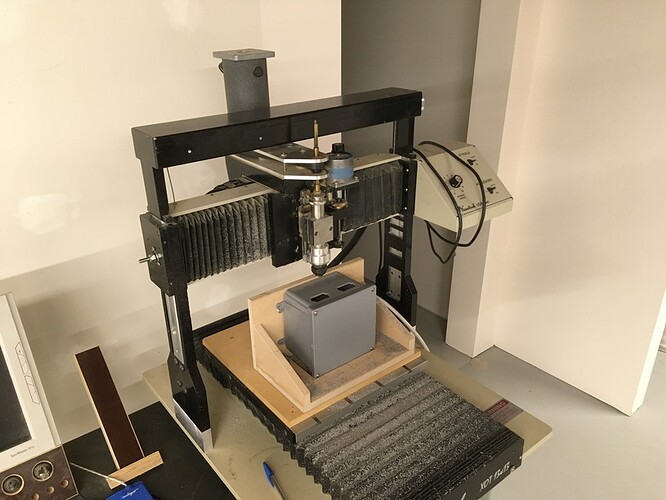

This is something I do not need to get because I already have one. Not a Tormach, but a heavily modified Xenetech 13x13 engraving machine. I got the machine for free, ditched the propitiatory control stuff, and modified the spindle to fit a standard router collet. The unit runs Mach3 machine control software. It is not heavy enough to machine steel. Perfect for wood and plastic.

Ever used a hand-router?

No different…

maybe slightly quieter, since there’s an enclosure.

that looks like a messy place to run a CNC.

actually, i mean it looks like a way too clean space to run a CNC.

Titan CNC just posted a video of it in his home on his YouTube (how I ran across this in the first place.) The machine itself is quiet, the noise comes from cutting material.

As far as the working area… There’s really not many turnkey mills this size and cost, and the ones that are available don’t come with a CNC controller like that. That allows the user to “graduate” directly into more capable machines while already knowing all the control software. That’s pretty cool. People curious about Tormachs for hobby use might be on the fence about $7,000 for their basic mill but $3k is less barrier. Plus you learn how to setup the larger machines at the same time so when you’re ready to upgrade, well, you go with the CNC controller ecosystem you’re already familiar with.

Just checked and HAAS also has a desktop mill on the way, using their standard controls via wireless connection.

Looks a lot like a slightly upgraded Bravo Prodigy or the “Click N Carve” which was rebranded and sold by Rockler. I am the (slightly embarrassed voice) owner of one of these. I purchased it hoping that being a Rockler product, it would be supported and a quality product. This was about 6 years ago, I think.

It actually wasn’t that bad. The software seemed toy-like at first but now, after using Vectric for CNC, it actually had many of the features you really need, but with brightly colored icons. My version only used 4mm bits which I found difficult to source, and it certainly did not win any speed contests. It did however produce highly accurate carves in wood.

If the Tormach unit does have an upgraded spindle, I think it would be a workable unit, but $3000 seems a bit much.!

Is it me, or is it the EXACTLY the same plastic housing mold and clear shield. Hmmm?

Looking at the Tormach site, I would bet serious money that the housing, shield, bed, & hold-down clamps are EXACTLY the same. The specs for the spindle does seem to be slightly better and the controller replaces the game-controller of the Click N Carve. Software is definitely different.

Hi @shop, this machine can make a lot of sawdust, but so far all I have done with it at the new house (basement) is cut out the openings in 27 of the junction boxes you see in the picture. If I do anything messier than that I will build a nice enclosure for it with a vacuum connected. I might have just the tool to do some nice Draftboard and acrylic pieces for that …

I have a dust boot on my X-carve and it does a pretty good job. Although realistically I’ve probably only used it like 3 times for anything that would make chips. I just don’t do that kind of stuff. But I’m having a lot of fun carving circuit boards.

Looks like similar capabilities to my Nomad 883. Which was my favorite toy before the forge and now sits mostly forgotten. The 883 lacks the fancy controller and fancy enclosure ( the nomad is boxy vs curvy) but has roughly the same work area available.

Tormach is explicitly targeting the education market with this; it’s aimed at getting kids familiar with PathPilot and CNC generally (my saying this is not a criticism of them or their product).

If you’re thinking about this, and aren’t in the educational market AND (big “and”) don’t need an enclosure, then there are a bunch of gantry mills available. I’m presently building this one:

…it’s remarkably heavy. I’m building the 35x35 version, and moving the t-slot table (just the table) around the house nearly killed me. Other people have finished theirs, and the acceleration & traversal speed of the stock unit is pretty remarkable (650 inches per minute X/Y traverse; people are having to slow it down because their supporting tables/benches can’t handle the forces).

Plus it’s got nifty options like a plasma cutter, 4th axis, and laser module.