I have never participated in a forum to this extent. Not even close. Part of the deal was the big unknown that we were all discovering together. Even though we all have different levels of experience and knowledge, aptitude and druthers, we are all basically on a level playing field: none of us has a Glowforge. Not even the GF team had a final product. That’s some serious social mojo going on. Knowing we all have this “vulnerability” or existential deficit allows for some solid altruism because no one has the upper hand. Even @dan who steps in and clarifies a few points here and there does it in such a way to build community and not from a power position. Seriously. Human beings are amazing at creating things. But playing well with others allows so much more to happen.

Well, thank you…cool!

This part really resonated with me and I’ve been thinking about this approach ever since I read it this afternoon. For some reason, this way of thinking has eluded me and now it all makes sense. I’m sort of going through this preparatory phase in a backwards way. I’ve been thinking…how will I make anything with this wondrous machine about which I know so little…instead of what will this wondrous machine inspire me to do and to learn and make. I’m going to let the Glowforge lead the way first, now.The rest will all come when the time is right. I hope that made some sense.Thank you for your insight.

Like @marmak3261, I don’t usually participate in forums much, just lurk in the background, but this community really helps to bring the Glowforge alive, My Glowforge is going to be driving a steep learning curve for me, looking forward to just messin’ with the Glowforge and seeing what I can make, spearding the word around the office to get ideas of other people as to what they would like making.

So I say “Hail to all Glowforgers, Whatever brought you here, lets just make the world.”

Yes, my thoughts exactly! The kinds of conversations happening here are fueled by a bunch of people all excited about what might happen, and as a result you get all these different voices providing as much insight and ideas as they can. I don’t think I’ve ever seen a forums board so positive and happy!

I skewed on the younger age, my experience mainly comes from hand/manual tools, I am male (but I can change, if I have to, I guess… Northern TV reference, sorry,) I do not code, but I am interested in learning (when I have the time) do looooove woodworking (not that I’m any good at it) and CAD (I am good at that). Blast I hate falling in the demographic ![]() I think @jkopel is right in saying that the forum is a limited pool to pull any accurate statistics out of. i.e. my fiance (a female) is an equal participant (she forbid me from returning the glowforge when I began to worry about the finances… blast you overtime) has no experience in woodworking, machinery, programming (bores her out of her mind,) or CAD. She’s leaving me to explore and post on the forum, cause I sit in front of a computer all day

I think @jkopel is right in saying that the forum is a limited pool to pull any accurate statistics out of. i.e. my fiance (a female) is an equal participant (she forbid me from returning the glowforge when I began to worry about the finances… blast you overtime) has no experience in woodworking, machinery, programming (bores her out of her mind,) or CAD. She’s leaving me to explore and post on the forum, cause I sit in front of a computer all day ![]() but it’s all good. those limiting demographics aside, were both excited about the glowforge, both coming up with ideas to create.

but it’s all good. those limiting demographics aside, were both excited about the glowforge, both coming up with ideas to create.

Bravo!

I have zero experience with CAD, but I love designing things, as well as making things, with lathes and mills and bandsaws and dremels and drills and many other tools, but my ideas are often limited by my skills…to be able to physically create what my mind can imagine…well, that’s just awe inspiring.

And let’s not forget about precision! That is a HUGE part of what this tool brings…to be able to easily cut and shape things to exact measurements & in straight lines & curves & freehand & increase / decrease size, etc etc…it’s too much for words.

But hopefully not to the exclusion of the former. . . ![]()

The diversity gathered here is a direct reflection of lowering the bar for participation.

Dan and the cofounders are delivering this technology to the masses, enabling people who wouldn’t otherwise experience this avenue of expression to indulge themselves.

(miscreants like me!)

At this point I am compelled to express my appreciation to the community here, and all they have taught me. The camaraderie and humor is as valuable to me as any number of cut files.

Also a shout out to all those on the forge team who work behind the scenes to make this happen!

The group that has accreted around this concept and gelled into this fine community speak eloquently of the innovation the forge brings.

Across all ages, skill sets and interests - here we are, drawn together by a dream of Can you make this not suck?". Well they are about to achieve that, and we stand ready to run with it … poised on the starting blocks.

There is certainly simplification of the user interface and setup which will open up the technology. But for me, it’s the price point and some of the unique capabilties. Wouldn’t have cared if they sent me a kit and said solder it together yourself as long as the advertised capabilities were in my budget.

Yes, it was the price that I could reach. would have been more than willing to educate myself in whatever technique/software that was necessary 25 years ago… no point in learning the tool if I would never have one.

Price point got me there, the ease of setup, and the scanning/trace elements are a cherry on top

Now I get trial by fire. ( < see what I did there?) That’s fine, I am better armed now, I needed this long to mature the level of patience I’m gonna need.

BTW, you sir have been instrumental in my education. Thank you.

You are indeed, eloquent…and I always enjoy reading your posts. You have an upbeat and positive attitude that really adds an important outlook to the forum. If nothing else, we are happy!

I feel I’m also one on the outside, while I would fit in the 30-50 age group (turn 33 in a few days) - i would have to say that the money for GF is a bit out of my comfort zone, but I consider it an investment. All the CAD, woodworking, and any tool use were learned (and respected) in high school. I dabbled in coding back in high school and college, but realistically, coding that old is considered ancient by today’s consideration.

I have always had a game making ambition, and I think it’s the ambition of wanting to make a world of potential to be made to happen is what drives the other people to go out of the comfort zone to hop on board the GF train. The rest of us just see the GF as a natural choice for the field, as the making community already are used to making possibilities come true.

There is a lot of truth in what you say. 5k was more than a bit out of my comfort range (finally paid that card off urg - I thought they were going to send someone out to kill me when I maxed it out!) but I really want to provide my daughter with the chance to be interested in science and making- to think like the maker and coder that I wish I was

The education and skills and ability to make this will provide us way more than offsets the cost. I’m getting exited that in just a few months the majority of us will actually be getting the machine (probably/hopefully/fingers crossed) and I’m ok to wait just a little longer than that

Yes, we are!

A diverse group who all jumped into the same boat together - and are building a team!

I predict that diversity is going to manifest in amazing ways here on the forum with many talents, and creative drives converging.

(2010 Space Odyssey) Something is going to happen - Something… wonderful!

Another favorite; Sometimes in life there’s a thing, there is a “before, and an after”.

My Forge is such a thing.

I have a one of the sorriest examples of a contractor’s table saw in my shop. I’ve tried to tweak it but can’t get it to cut straight. Sorry excuses for miter gauge and fences. I could have bought a good cabinet saw for what I spent on the Glowforge, with all kinds of bells and whistles. I am sure that I would have many more years of use out of that saw and get so much more done with it in terms of furniture and other projects. But I can’t fit it in my office! The Glowforge a desktop machine. Small format, but will still take care of all the small bits and pieces that are so hard to make precise. I’m getting close to finishing my home made bandsaw. Once I get the Glowforge, there are lots of little pieces that I’ll remake to look more precise. Making the knobs and the blade guides with a Glowforge will produce such a neater result.

After seeing your bandsaw project, I recognized a kindred spirit. Cool project!

I wanted a lighted dual head dustless polishing machine to finish jewelry, so I built one from an abandoned aluminum mailbox and a capacitor-start washing machine motor. A v-belt shieve pushed down on the shaft to drive the heads, with a 15 inch fan blade mounted on the end of the same shaft, with an old enameled canning pot with the bottom cut out forming the fan shroud.

Yeah, it ain’t pretty but works like a champ.

An old (1900) bank was going to be demolished and they ran an add for slab marble, $5.00 sqf. You pull it off the walls yourself. I walked out of there with enough to do two bathrooms.

So I found myself in need of a diamond saw with the reach to do 4x8’ pieces.

I mounted a 2hp. Motor, and a brick saw arbor on an old radial arm saw trolley.

Had a piece of 1/4" steel sheared to the width of the trolley x 9’. Mounted a 1/2" thick strip of plywood to it for clearance and cushion to protect the stone.

The blade guard that came with the radial arm was drilled on both sides to accommodate the water delivered to both sides of the10" blade for lubrication/cooling and flushing the cut.

Works like a charm.

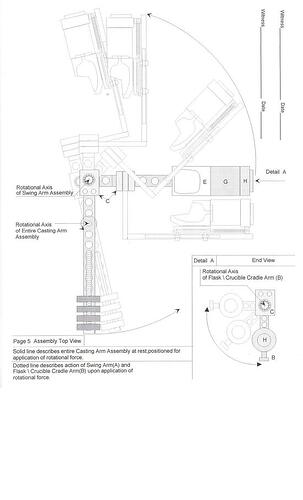

In centrifugal casting, the spring driven, “broken arm” design left a lot to be desired. So I re-engineered it. ( after I sprayed molten sterling across my belt line. I am confident I currently hold the unsubstantiated world record for how fast a man can remove his pants over his shoes)

When the spin arm is released, the molten metal tends to roll up the side of the crucible (close to being thrown out) before developing centrifugal force slings it toward and into the mold.

By incorporating n additional horizontal axis of rotation below the swing arm, the crucible and mold are free to respond to the force and roll up to the side instead of just the molten charge.

That is the biggest innovation since the design’s inception. It essentially changes the force from a hazard to a stabilizing influence.

I’ll see if I can dig up a diagram.

I derive as much satisfaction out of building the tools as using them.

So I know you will get a little grin on your face every time you flick that bandsaw on. I understand.

here we go…

The machine is driven with air pressure, which allows for adjustment from 25 psi, akin to a gentle hand pour - to 85 psi which is equivalent to filling the mold with a drop-kick.

my working prototype has served me for twenty years, and never once threw any metal out, even with the crucible filled far beyond normal.

That is beautiful.

I used to do a lot of casting as well, and the shroud around my machine had a pretty thick built up line of various metals running all the way around it. Never had to pull my pants off, but I can imagine a scenario were I would (shudder).

You should be marketing that!

Thank you my friend, that means a lot coming from you. From your posts, I knew you would understand.

I am an artist/tinkermiester/poet. I suck at marketing and business. I have many talents in life, making money has never been one of them.

Your description of “shroud” reminds me of the Neycraft machine. Nice.

I was sure this idea had worth. I knew it would work before I built it. It’s so simple it’s obvious.

I went as far as doing a patent search and saw there was nothing like it, but I perpetually lacked the resources to pursue a patent, and the deeper I dug into the process the more disenchanted I was, so I just used it myself for the next 20+/- years.

The best little innovation I ever came up with. I was sure that was my ticket. Unfortunately, Dave’s universe “excretes” other requisites upon me… You know, “The best laid plans of mice and men”. The need to eat almost every day.

I am, however armed with a returned date stamped copy from the PTO acknowledging receipt in their document disclosure program, which doesn’t provide any protection - other than establishing a date of proof of concept… maybe.

And I apologize for hijacking your thread @Xabbess…