I’ve been keeping the purchase a secret from my brother, who’s an architect and loves to tinker with things. It’s been killing me to keep my mouth shut as I know he’ll love it and want to come use it all the time. I just keep telling myself that it’ll be such a great surprise when I can hand him something I made on it—I can’t wait to see his face.

This is what I made to do the wheels on the bandsaw.

As far believing in the Glowforge, my family really thought I was crazy, even though I kept telling them that this is a BIG DEAL!

I showed them, and you all will soon too!

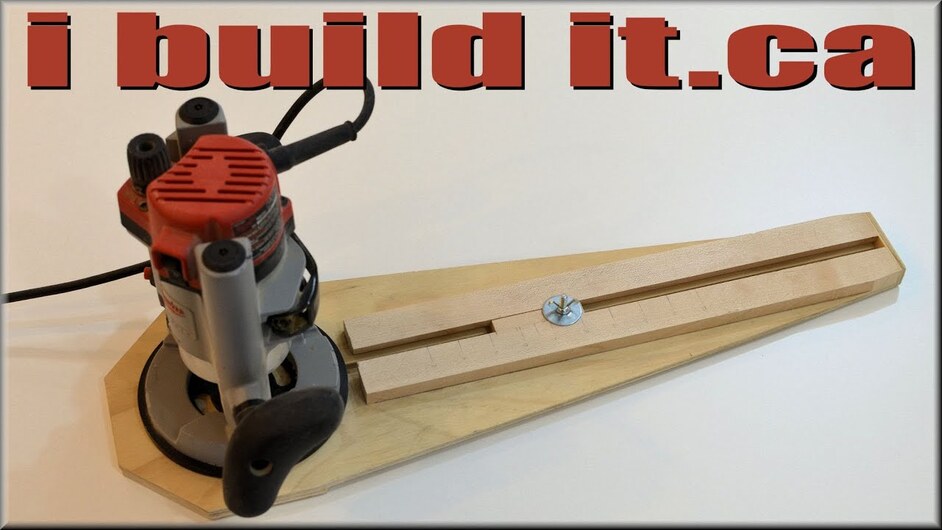

Ever think about how much easier it would have been to make that jig with a laser? Friction fit the router base into the ply.

Glowforge: the ultimate jig and pattern maker! (well not ultimate, but a pretty useful one.)

Heh. I actually told my brother, a mechanical engineer. He originally mocked me for it… told me I wouldn’t be able to use it, need to learn CAD software, it’ll be useless for me, blah blah blah. Over the course of the past year, as I’ve overcome all of his objections, his tune has changed. Now he thinks up ideas of his own. He appears to be growing more and more excited about my purchase.

- Tom

Ditto. Except no one on my end is questioning the choice to buy one, they’re all coming up with increasingly long lists of things I need to make for them when it gets here. And the more time that elapses, the more elaborate the requests get.

Thank god I didn’t end up upgrading to a pro, or I’m pretty sure my brother’s first request would be a stand up paddle board.

Ooooh. LOL, now I get it…

Because he’ll be delighted with your design and thoughtfulness of giving him something? Or because he’ll be uber-jealous? ![]()

Either’s fine with me. If people aren’t going to be envious that I have a frickin’ laser, something’s wrong with them.

- Tom

I purchased a Cricut Air about eight months ago to experiment with cutting precision gaskets. I have problems with circles being oblong sometimes. The blade can drag and deform the edge just enough to make problems. The blade drag also deformed the edge by ever so slightly compressing the material downwards and inviting high pressure liquids to wedge into the deformation and cause earlier failure. Looking forward to the Glowforge.

So it’s the combo of device with the material your working with, huh. I imagine you’ll still need to dial in your specifics with the Glowforge. But I also imagine that’ll be really easy and once you find the sweet spot, that’s it… you’ve found it.

- Tom

I don’t know what different blade options there are for the Cricut, but with my Graphtec I would probably switch from the standard duty 45º blade (for material less than .25mm) to the 60º blade (material .5mm to 1.5mm) I use for rubber resist material.

It will still compress the material more than a laser beam.

Is an excellent use case for lasers. Cuts great and you won’t be getting issues with deformation. The only thing you need to be aware of is where the kerf will be so the size is correct and any holes or cutouts inside the body of the gasket are sized correctly with the kerf in the cast-off piece of the gasket cutout.

Both, definitely… But really even more the surprise that he knows I’ll let him use it anytime he wants.