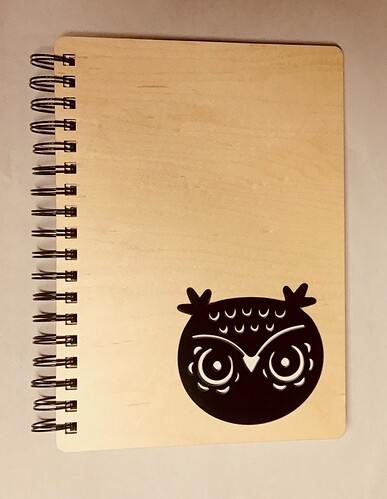

Not sure what I was thinking, this was my 3rd print ever and I decided I wanted a maple journal with an acrylic owl. Six owls later…before I figured the kerf out. It ended up being .003 but still needed a tiny bit of sanding. Never adjusted kerfs before there is probably an easier way than changing the stroke width 6 times (feel free to share any kerf secrets you may have) I guess everyone gets an owl ornament with their presents this year : )

Pretty awesome, thanks for sharing

Stroke thickness is how I do it too. The thinner the material, the smaller the kerf is because there is slightly less burning needed to cut through. .007 is my general measurement for medium plywood.

It’s a process always and different materials can throw you since they get different settings.

Looks nice though.

I get it…been there done that, myself. Took me a long time to understand AND to make copious notes about kerf…but, after lots of testing, wasted materials (not really wasted when you learn from it) I finally figured it out. I felt immense self-satisfaction, then. You’re already part way there. Your journal looks great!

Looks nice!

One of the best kerf tips is to remember that a laser cut channel doesn’t have perfectly straight sides. Because of various factors, it’s more V-shaped.

So when you’re going for a nice snug fit, flipping one material over will make the wall angles align. Your tolerances can be a bit tighter, it will be easier to press together, and you’ll get slightly better results.

I did not know that thanks for letting me know. I thought it was strange that it wouldn’t go in from the front but went in snuggly from the back.

This is adorable! Very well done

Congrats on working through your kerf requirement!