I’m sorry that you’ve had trouble with your Pro Passthrough print. So that we can look into this for you, if you haven’t done so already, will you read the section titled “Things to Watch Out For” on our Pro Passthrough support page, and then run a test print?

Here are the steps for the test:

-

Load a sheet of material into the Pro Passthrough slot and ensure that the portion sticking out of the printer is supported so the material lies flat on the crumb tray inside the printer.

-

Double-check that the material is completely flat against the crumb tray. A quick way to do this is to press gently on the material where it rests on the tray and feel if it moves. If not, you’re good.

-

It can help to use pins to hold the material flat against the tray. For example, a lot of customers use small pieces of scrap to print these pins available in the free laser design section.

-

Open the Smooth Curves Stencil from your design library.

-

Turn on the Pro Passthrough feature in the menu bar.

-

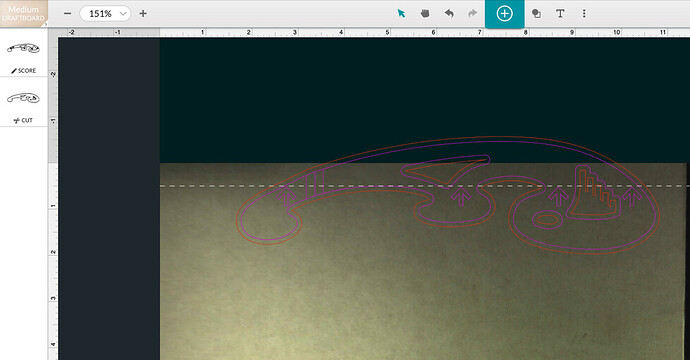

Select the entire design, and arrange it so that the dotted line at the top of the work area is at the tips of the arrows in the design

-

Click Print and run the first section of the design.

-

After the first section completes, move your material through the Pro Passthrough slot so the printed area is more than 3 inches away from the front of the Glowforge.

-

Follow the prompts and run the 2nd portion of the test print.

After the test print completes, please send us the following:

- Photos of the front and back of the finished print.

- The date and time you ran the test along with your time zone.

- A photo of the bottom of your print head showing the lens and both windows.

Thank you for sending us this information. We’ll retrieve the data from this test print, review everything and follow up with next steps.