@Scott.Burns, it’s interesting to note there is no blooming in the linewidth when cutting anodized aluminum, regardless of movement speed. The beamwidth appears to be well controlled, even when stopping one vector and starting another.

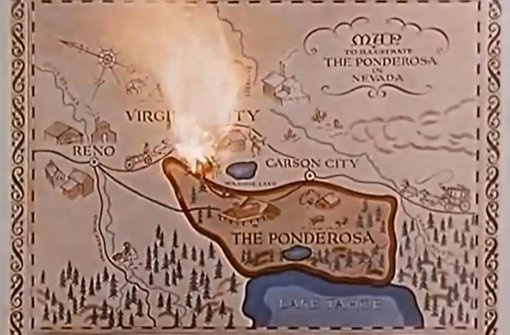

Nonetheless, I think fluctuations in movement speed is the issue that GF needs to keep working on. I’ve witnessed the laser appear to park-and-burn, usually where two straight lines meet - like sharp corners. When I see this, it triggers a childhood memory:

I’m a bit mystified why GF doesn’t see this problem and fix it. There’s no new science here, the 3D printing industry figured it out a long time ago, and the GF is basically a 3D printer with photons instead of plastic.

I try to minimize the effect by keeping the beam moving as quickly and smoothly as possible. I radius corners wherever aesthetically feasible so the software blends more smoothly between X and Y movement.

Below is a test pattern that increments the corner radius, from left to right:

This is standard printer paper, speed 500, power 1, and 6 passes. You can see a slight amount of blooming in the first (radius=0) corner. If you turn up the beam power, that will be where the paper catches fire.

If quality is a priority and you’ve all kinds of time to burn, you can cut paper using Engrave mode:

I converted the vector file to a 1355 DPI png file and rotated the image to minimize the line segments parallel to the X-axis (left-right) motion, as GF’s algorithm for thin lines gets dodgy. I set the engrave speed to 1000, power to 5 and 3 passes. It took about 15 minutes to complete - compare this to the previous vector-based run that only took about 5 seconds. Like I said, you can’t be in a hurry for this method, but my GF spends a lot of time sitting idle, and the time I spend cutting is typically a tiny fraction of the time I spend designing, setting up the job, and post-processing the output from the cutting process. Your mileage may vary.