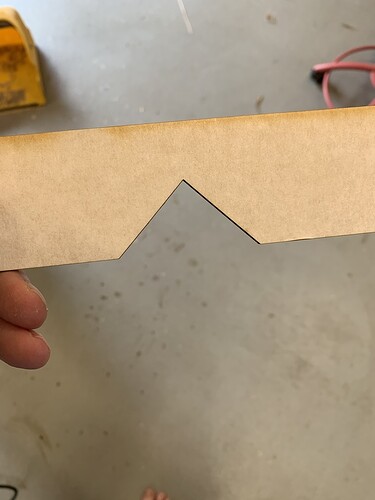

Needed to set my plunge router to a certain depth, for a bunch of repeated cuts.

Preach it brother (or sister as the case may be).

Very nice practical cuts. Now we want to know where this is leading?

What a cool idea.

In a blend of old and new, I used the glowforge to make the router alignment jigs to cut a vee-shaped notch in the top of an 8x8" timber for what is called a steplap joint in a timber frame. The steplap is in the top plate of the frame and accepts the rafters, while providing resistance to outward forces (snow and other roof loads).

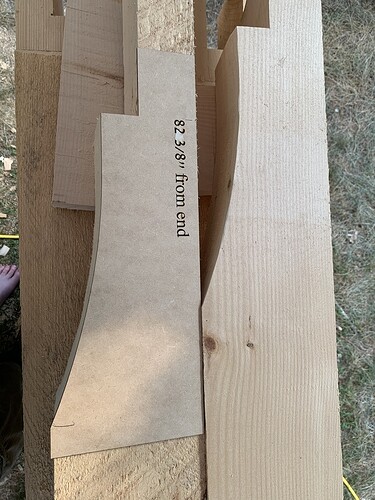

Also used the glowforge to make some layout templates, in this case for the rafter tails.

Here is the rafter tail jig showing how it was useful for the layout of the rafter.

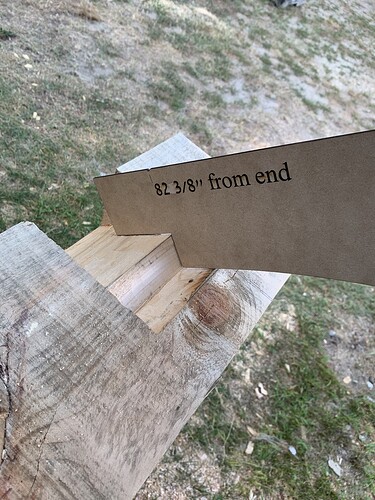

And here is the rafter tail jig testing the fit of the steplap joint in the top plate.

Excellent! Love practical cuts like this.

Great use!!

I do love a good practical project! Very nice!

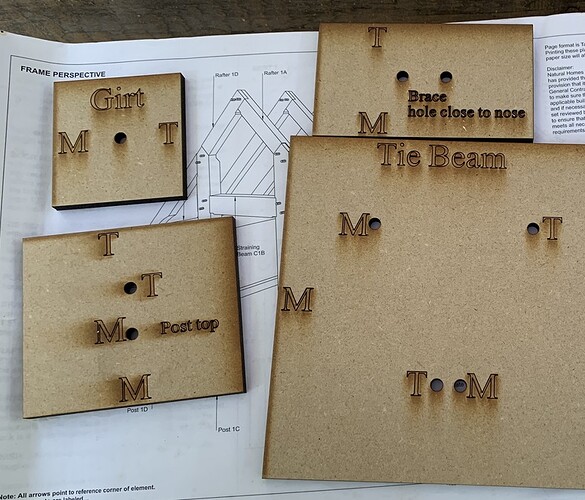

Here are some more jigs- these ones for repetitive placement of holes for the wooden pegs (trunnels) that hold the frame together. Each mortise and tenon joint has one or two pegs. The holes are offset slightly so that driving home the peg tightens the joint (this is called drawbore).

So for each type of joint, I made a template of 1/4” mdf with pilot hole locations. For laying out a mortise, align the “M” side of the template with the edge of the mortise and the holes marked M are where you drill. For the corresponding tenon, flip the jig and use the T against the shoulder of the tenon. The dimensions are shifted slightly from the M to the T layouts so the desired drawbore is achieved.

I know this is a rather specialized use, but hopefully the overall concept prompts some “aha!”moment for some of you!

I can’t speak for all but I love things like this because I have learned to extrapolate from the specific to the general and the broad concepts put my mind abuzz.

I’ll be building some tool stands soon and very likely will make screw placement templates like these.

I think you should have hand chiselled those joints.

Why do I think that? well because I have been too busy to 'forge. and if I can’t forge nobody can. LOL

very clever though. I have some projects that will require some router jigs. as a matter of fact while I was typing this I thought of another one. Who exactly do I see about making the days longer and the sleep requirement less? anybody? Bueller?