And… another one: The daughter of two good friends of ours just graduated college, and a group of us are doing a “Graduation Parade” in cars, with appropriate social distancing later today. My wife wanted to make some hand signs using cardstock with memes / pictures she found on the internet, and asked me yesterday if we had Paint Stirrers / Stick that we could use to hold them up.

I said yes… and then realized that the only ones I had were the smaller “tongue depressor” style, which wouldn’t be big enough. Then, of course, it hit me! I have a Glowforge. (Seems to be a theme, right?)

Looking at some of the paint stick stirrer designs on Amazon, one of them actually had a ruler next to it, which made it VERY easy to determine where to design and cut the shape for the handle.

Note: because I was doing this “quick and dirty” I did not bother to clean up the design - just let the extra cutting around the hanlde section cut - adds maybe 10-15 seconds per stick of cutting time - and would have taken me much longer to edit the nodes, split the path, remove the extra sections, and re-join them. (I’ll post the design in Free Designs in a bit.)

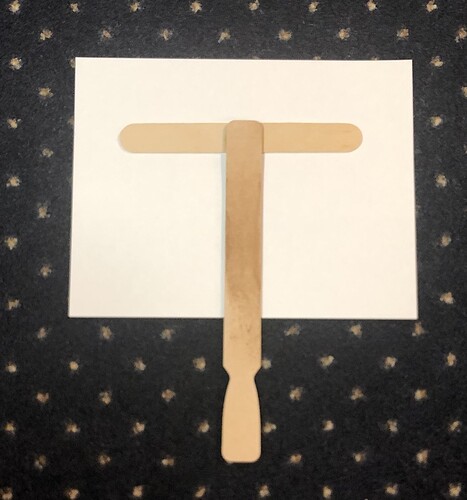

Made 14 of those (from a single sheet of draftboard @ $4.00), cleaned off the edges - using a generic magic eraser - with all of them taped together (it’s much more efficient that way), and paired them with the Tounge Depressor style smaller sticks to create a T-Shaped holder.

(I chose to design just the regular paint stick and cut it, gluing it to the “tongue depressor” style ones I already had because to create a T -style in the draftboard would have taken many more sheets, and I already had a bunch of the other part.)

Used TiteBond II Wood Glue and mini clamps to secure them. Once dried, attached the signs - printed on cardstock - using Elmer’s Multi-Purpose spray-on adhesive.

They are incredible stable, and the design seems to work really well.

Here are pics of the holder from the back,

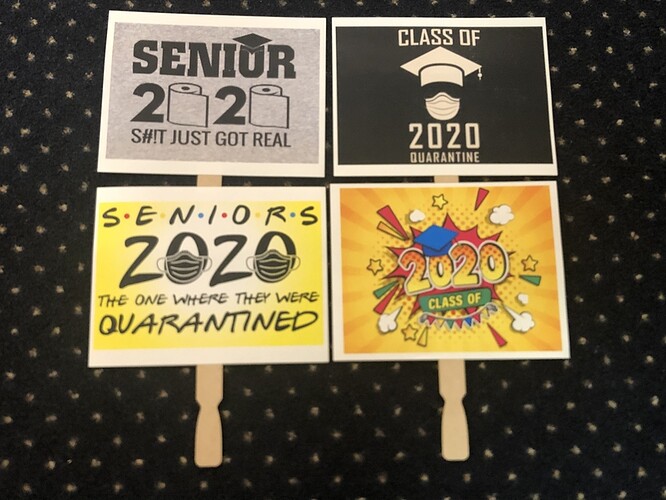

the 4 different signs we’re going to be sharing with other parade participants:

The “Friends” themed one is my personal favorite.