I’ve misplaced most of the pictures and part numbers but I will let you know what I can.

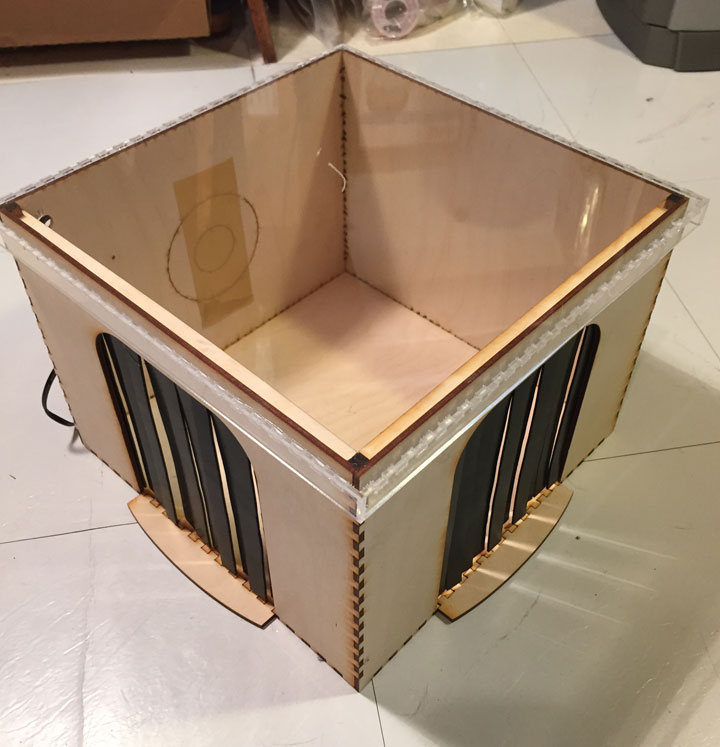

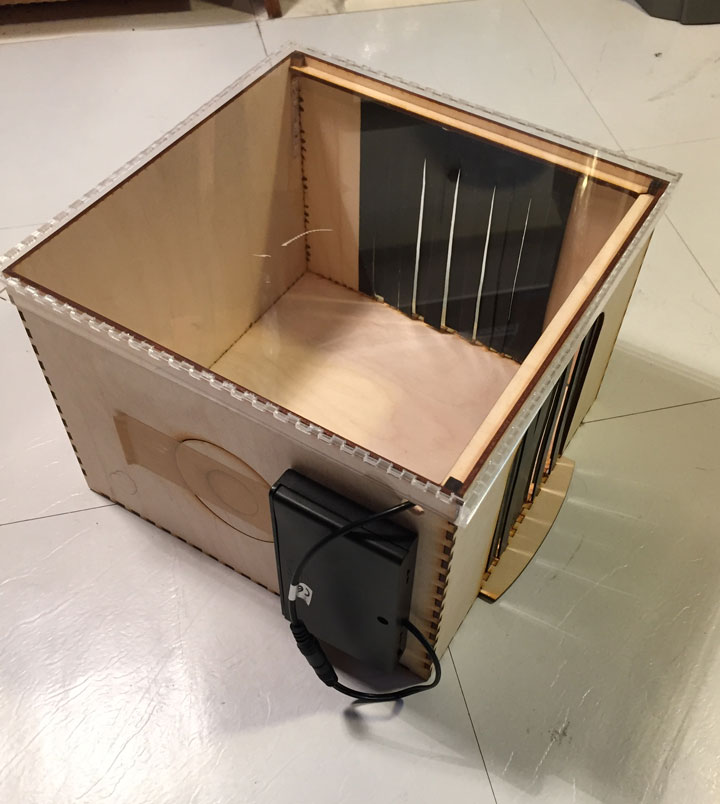

Mainly you need a big plastic tote box, or some other container which is big enough for your hands, tools, and work item. You then cut holes for two 4" PVC “toilet flanges,” which provides an inner lip. Mark the holes and drill for the matching nuts and bolts, which you figured out while you were at the hardware store. The exact dimensions don’t really matter as long as it holds together. You can see my bolts are too long, but it doesn’t hurt anything.

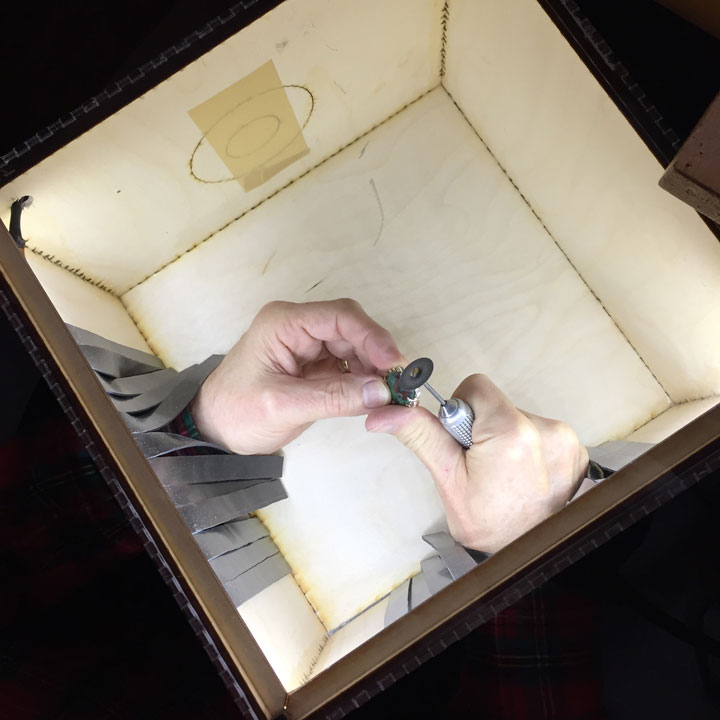

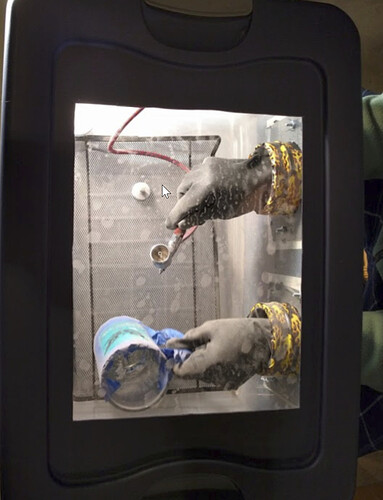

Stretch the cuff of your rubber cleaning gloves over the lip. I secured mine with duct tape–for abrasive etching, I don’t want ANYTHING escaping!

Because I am using abrasive and the bottom of the box will quickly get covered, I needed a raised platform which I could set the work piece upon, but which would also let the abrasive dust fall through. I found a cheap wire mesh tray at an office supply store.

I don’t have good pictures of the lid construction, but I just got a piece of acrylic or lexan at the hardware store for a window. I cut a hole about 1" smaller than the material and used silicone goop to glue it down.

Here’s a different image of the interior before it got filthy.

The project was very easy EXCEPT the milky plastic crate is easy to crack when you cut it. That is why there is a lot of extra duct tape in use! I used a Dremel tool and a utility knife to cut out the 4" holes, and if I pressed too hard with the knife the plastic would flex and it might crack. It would have been easy if I had a hole saw and backed the plastic with sacrificial wood, but… I didn’t have the right things on hand, so I just did it sloppy.

No lighting, as you can see I just aim a shop light through the side. Works OK.

If I wanted to make something fancy and sturdy, I’d make or buy a wooden box, but for my occasional use the plastic is holding up OK. I’d like one of these but I spent about $30, not $200. If I had to use it all day, though…

solution! The rubber curtains are a fantastic!

solution! The rubber curtains are a fantastic!