I guess I should mention what I have the glowforge sitting on.

Table top

Legs (Qty 4)

Storage system

And two of these on the Glowforge on the left.

One has sharpies, two metal rulers, carpenter pencils. The other has magnets, utility knife and microfiber cloth for the lid.

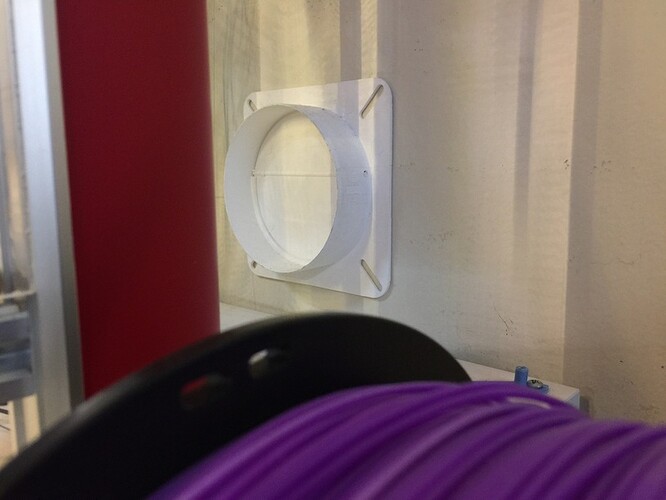

As for the exhaust. I have two gravity type blast doors. One directly on the inlet (where the 'forge connects too) and the other is right after the booster.

Directly behind that (the inlet for the 'forge) I have PVC pipe (4" ID) going into up to the crawl space. Then a run to the in-line booster (200CFM) then another run to the outside. (This is controlled by a super nerdy z-wave controlled switch.)

Though, this setup is not glowforge approved as it has more than two 90 degree bends. And I did have issues in the beginning where some of the smoke was exiting the mid-section of lid. But with guidance from support I found a folded manual stuck in the last 2.5ft of the run just before the exit. Absolute noob mistake on my part. But after removing that. The setup works great.

But once again. Not glowforge approved. My setup is unique due to the fact that there are no windows on that wall where the glowforge sits. Moving it to near a window would have meant that we’d have to completely redo the office- That was not going to happen. So I made due.

Inlet for the Glowforge

Provided 4" flex hose

PVC Pipe

Outside

I have no pictures in the crawl space. I am 6’ 2". And it’s a crawl space. I just wanted to get that part done and GTFO. I hate it up there.