@Dan confirmed that a couple of months ago when I posted about my PRU. I didn’t want to use the 100% setting if it was going to push the tube past rated values like the K40 ![]() I was looking for something like the Redsail config file that lets me make 100% in the software equal 95% of rated tube power so I don’t prematurely wear it out (the last 2-3% power causes a hugely disproportionate reduction in tube lifespan) or overdrive it which is even worse. Dan said that 100% in the software is set so it achieves the tube lifespan they’re projecting.

I was looking for something like the Redsail config file that lets me make 100% in the software equal 95% of rated tube power so I don’t prematurely wear it out (the last 2-3% power causes a hugely disproportionate reduction in tube lifespan) or overdrive it which is even worse. Dan said that 100% in the software is set so it achieves the tube lifespan they’re projecting.

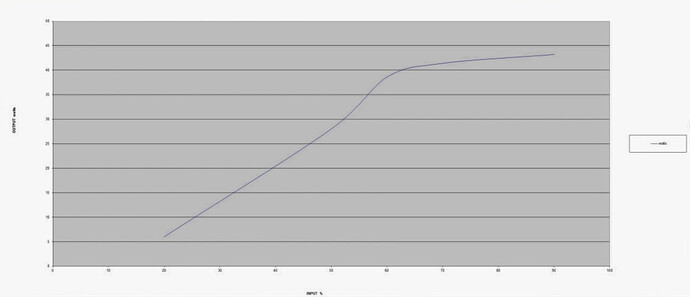

yeah. this is a good visualization of the top end inefficiency in laser tubes: (supposedly a 50w tube, from RDWORKS video)

Yes so that had a minimum power of about 7W, 14% of full power. If the GF tube is similar it doesn’t make sense to have a 1% to 100% scale that is 6W to 40W. It is just misleading. If it showed 6W to 40W then it is obvious that there is a signifiant minimum power and that 20W is half power. On a linear 1 to 100 scale half power would be 41%, where is the sense in that?

I don’t have my glowforge yet but we know from @dan that the power is not linear, so if you put 20w and cut a certain depth than 40w will not be twice as deep. So maybe the % will be scaled in a linear fashion. Would that satisfy as a reason to use %?

The effect it has on a particular material might be non-linear but you can’t hide that because it would vary from one material to another. The way acrylic is evaporated is completely different to burning away wood.

Do you think 50% burns half as deep as 100% by some magic power curve? I doubt very much that is the case.

I would assume if they went with % then yes it would be linear. I don’t assume that wood and acrylic take the same % but again if wood takes 15% for a depth then 30% would double that depth, if acrylic takes 23% for a depth then 46% would double that depth. I’m not as dense as to assume wood and acrylic would cut same depth at same %. Again I don’t know that’s the case but that is how I assume it will work when the software is completed

I don’t think there is a magic curve that makes it linear for more than one material. It you tune it for acrylic then I expect it will be somewhat different for wood.

Currently 1% is far more than 1% so it certainly doesn’t cut 1/100th of the depth that 100% cuts.

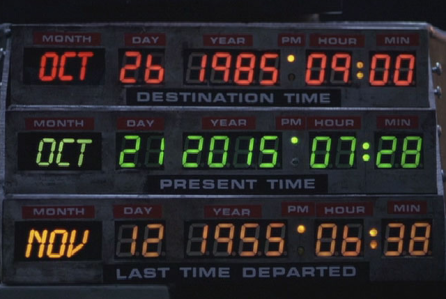

Forget it, neither one of us have the laser in hand so this conversation is pointless. Like arguing over using the time machine and which date setup would be better. Doesn’t matter because neither one of us can use it

I have a laser diode about 6 inches from my left hand at the moment. Just designing a bracket to attach it to HydraRaptor at the moment. So I will soon start experimenting with 3D laser printing myself as fed up waiting for GF.

Indeed - top power is optimized for both cut speed and lifecycle. The funny thing is…

…this is absolutely true. The high end lowers tube life without giving you meaningfully better cutting results on most systems.

MM/DD/YYYY

it must hurt to be this incorrect about a topic

(i’m just annoyed because it’s reversed up here so i’ve switched to adding letters)

Letters are correct, at least according to Mr. Zemeckis.

But still Month/Day/Year!

Yes! But you wouldn’t believe the push back on that! Lol

I can’t imagine the amount of cringes that go through the office whenever you post an update of any kind good or bad. Someone always, without fail, picks it apart

I’m still a little frustrated that nailing two 2"x4"s together only gets me a 3"x3.5" support.

️

️

ISO 8601 says YYYY-MM-DD. End of discussion. ![]()

Well, ISO 8601 wasn’t published until 1988. So I suppose Mr. Zemeckis gets a pass on that.

️

️

You have no idea. ![]()