I just tried that new beta passtrough update and it works great. At least for my first print.

I normally use snapmarks since I do a lot of work that is to large.

Using the passthrough software makes it so much easier because I don’t have to slice the artwork manually, I just wish that the camera would not take so long to take the pictures after each print and that there was an option to change the way you feed your material in and not just through the back. On the set up that I currently have I always feed the material through the front.

Also what is going to happen if you cut a big artwork just to realize at the end that some of it didn’t cut all the way through? there is no way that you can go back and re cut that one step like with snapmarks.

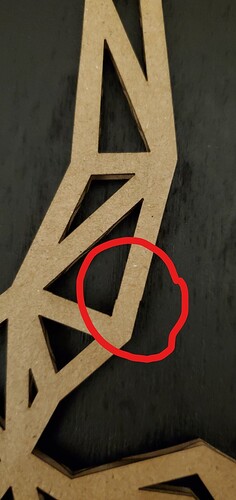

This is the artwork I did on piece of cardboard with 3 steps.

On the last step I set the material to a 25 degree angle on purpose to to see if the alignment would still work, and apparently it did. Not perfect like the rest but is something that is hardly noticeable

Looks really good.

The material flow is definitely backwards vs the hardware design. The machine is designed to load from the front and the seals are biased to allow material to easily move front to back. This mismatch makes me think that the software designers had not seen the a forge or looked at any of the marketing materials (which tend to show the material being fed from the front when they show the pro). before they started their work.

That backwards design also makes moving the parts more difficult as they move against the bias of the flaps and I find that I often have to take everything out of the machine to clear up a jam. I suspect much of this would be avoided if the flow was reversed.

It also increases the potential for ruination due to knocking into your material during the later parts of a multi move cut. The amount of material that protrudes out the front increases as your cuts progress making such a collision more likely. I prefer risk up front yet much of the passthrough design causes the risk of failure to grow as you progress. I would love it if they flipped the work flow to match the hardware design but have not gotten my hopes up about it.

Just as it would make more sense for the engrave to work from back to front so it didn’t deposit fresh char/stain into/onto what was just engraved?

Just got into the beta as well. Too bad I can’t load app.glowforge.com in my browser now. It looks like it loads correctly. I get a glowforge error (oops, something went wrong) and then I am met with a giant Glowforge logo (more than screen filling) I’m on chrome and never had this error before.

Edit tried reloading the page again and now it works

The seals flex either way once you’ve pushed material thru them in that direction. If you’re only doing passthrough jobs, they stay that way until something pushes them back in the other direction. I just ensure the front one is pushed “out” before I start a passthrough job (I use it from the front a lot more.)

Good experiment to perform. Thanks for reporting your findings.

I applied a little late for the Passthrough beta testing! (Just within the past week) But if you guys would please consider adding me in, IF IT IS NOT ALOT OF TROUBLE, it would be greatly appreciated! I did send an email, letting support know that I did apply, and asked them to consider it. I am not sure that I have received a response yet. I will double check. BUT I WOULD LOVE IT!!

I am oh so excited to find out! I have been busy lately, so I have missed my daily dose of forum check ins, but am trying to get back to normal. What is normal, anyway? I am unsure. But in the direction of my normal. HA!

They’ll eventually get to it. I sent it in and didn’t hear anything for a month and a half so…it’s Glowforge time.

I tried my first passthrough software print and it was a bust. Thankfully I tried on cardboard. Software looked to work fine on the first step but when it went to take the picture after the first job it stated unsuccessful. Had to try manually and at the focussing step got an error to reset the browser and power off and on the machine again.

After shutting it down and restarting the machine manual alignment and focus was back on again and I’m now finishing the second cut.

Second cut looks great! Alignment of the cuts is “off” by a tenth or so of a millimetre.

I’m proceeding to make the same file in wood.

File in wood had awesome alignment! The one thing that the passthrough maybe needs more than regular cutting is automatic cutting from the inside out. With material hanging out of the machine front and back making sure material is flat is a task. I my case I used bedpins inside the machine and sawhorses front and back. Thing is, the mpx I was using has a bend in it. So when the machine cuts out the perimeter first the natural bend in the material pops up again and the inside cuts are either slightly off or not all the way through.

Love to finally being able to use the passthrough with ease.

Just used my passthrough beta for the first time, no survey came up after I completed the cut. I am guessing it was because I had to switch to manual alignment for my final cut. My piece was done in 3 cuts. The first, worked beautifully - lined up perfectly. The second cut was off and the final cut would not load at all and I needed to manually align. Once it gets to the point of all working like my first cut it’s a no brainer. For a first shot, not bad at all.

Been using this off and on, and it is seriously MAGIC! Fantastic job on this, very happy with it!

So after using the passthrough beta software quite a few times I wish that they give an option to cut the same layer again instead of just giving the options of ( Continue, Align Manually or Realign ) Also that on the last cut the artwork should stay on that one position and not reset to the original place.

Again just in case that that layer needs to be re-cut, align it manually is just impossible.

That has happen a few times to me that I really need to cut the last layer more than once.

I imagine I’m not the only person that don’t use profgrade materials and is not always

a for sure thing that it will cut all the way through every single time for whatever reason.

Honestly Manually align shouldn’t even be an option as the lid camera will never be as accurate.

This it just my opinion.

I still love the software though every single time has been perfectly aligned

HUGE improvement!! The automatic slicing and aligning have worked amazingly well… for the most part.

My test so far consists of a large living hinge that requires 3 prints to complete. The slicing and auto-alignment worked flawlessly for the first two slices/prints but there was an issue after the 2nd print finished. I repositioned the material and was attempting to start the third and final print when I noticed the GF interface said the 2nd print had failed (although it hadn’t). My only option was to manually align the 2nd slice or to cancel the print. I had to cancel.

In addition to ‘Cancel’ and ‘Align Manually’, it would be nice to have the option to select any slice and have the GF attempt the auto-alignment process again with the selected slice.

In the event the interface has a hiccup (like mine did), this would allow you to salvage an otherwise ruined print. It would also allow for multiple slice prints to be resumed should you not have the time to print all slices successively.

Dan and team, THANKS for the continued work on features like this!!! You are exceeding expectations and making a great machine even better.

First time I tried to use it, I got into a repeating error aligning print head and failing to print. Turned on/off and tried again.

First part of cut worked well. Then had problem aligning second cut. The software was a bit confusing because the pop-up said that the cut was not aligned, but after second attempt it did align correctly but the persistent error message still floated over the screen. I just had to accept and continue. Similar to others comments, alignment was very close (within a few thousandths). Overall was pleased to see progress after all these years.

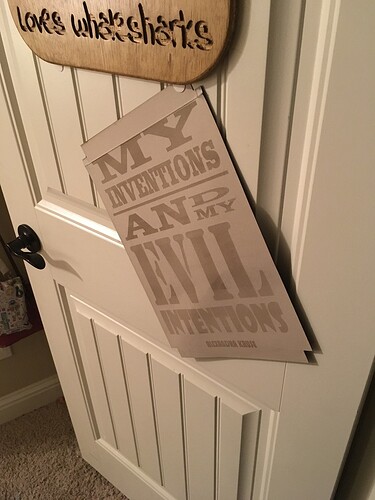

Credit Diresta with phrase…

I have the bought the pro last October and I wasn’t sure what I need to do or haven’t done yet to be able to use the beta. I was reading and I throught I saw somewhere where I’d have to pre-purchase the beta for my pro when I was ordering it? I sent an application to be willing to be a tester. I guess I just want to know if I can be able to use this new program at the end of this.

Dan covers it in his post.

Thank you.

Dear Glowforge Team

I run 2 different Prints with 3 sections each. The alignement went perfectly. It was dead on every time in the first try. I’m really happy with this new SW-feature!!

But one Thing didn’t go as expected. I’ve never got a Survey to fill out - not for one of this six prints.

But I think thats more dramatic for you ;). I’m really happy to be able to use the passthrough now! Thank you very much!

Hi all!

I just received the Beta, but have been unable to get it to work. Each time, I hit print it says “Print Expired, Unable to Print, Try again in a few minutes” and then my machine goes through centering. This happens each time I try. I have shut everything off and reset everything.

Any tips on what is happening and how to fix it?

Thank you!