Nice.

Yes there is also a place just across the water in Port Angeles. I considered using them but in the end I just waited it out.

Yes, still a ferry ride.

Yeah pretty much an all day adventure. Then if it had been damaged in transit I would have to refuse it and come home empty handed. I think too if I recall correctly the ferry timing was very tight and I was worried I wouldn’t even make it back same day.

I get it. Sumas is a 30 minute easy drive for me and I usually walk across to beat the lineups. I of course did not hand carry my Glowforge across the line. It’s heavy! I have walked across with a 32mm ballscrew 6 feet long though. CBS thought that was interesting. It weighed about 35 lb.

Haha, crazy.

I considered getting mine delivered and bringing up but it takes me about 14hrs of non stop driving to get down there. and was worried i would break it and not be covered on my warranty or something silly like that.

Yeah, not worth the drive.

Yeah there’s that too. If it broke down under warranty you would have to drive it back down to the location they shipped it to in order to return it for service at their expense. Then you’d have to go pick it up all over again later.

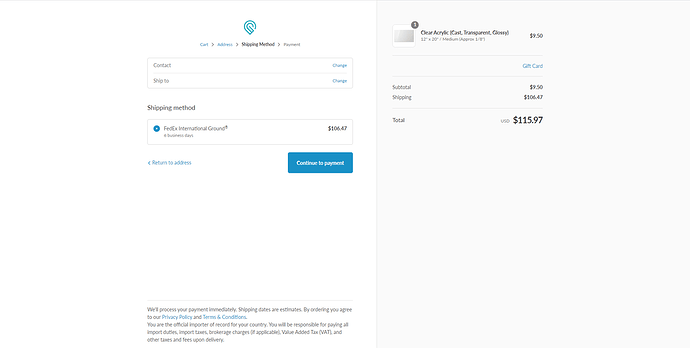

I was wondering because you are close to the border, when you go to order proofgrade materials if you choose to get it shipped to your door is the shipping as crazy as mine? for me getting even a single board costs around 100$ and just gets worse from there with every added piece.

I order Proofgrade material to the shipping company also. It’s called “Ship Happens” seriously.

I use it for hobby use - it gets tricky when CBS labels something “Commercial Import”

This is where my shipping costs start at getting it sent from glowforge ![]()

I have some family members in Creston so i might try and get it sent to a po box in the usa near them

Whew.

Wow that’s crazy. I make my own panels.

Yeah pretty nuts, I just buy from windsor plywood in town. they cut up the sheets for me and the prices are pretty decent. Most of the things i make are form the same type of plywood and costs me about 25$ to get a 4x8 sheet and that yields me 20 pieces at ~11x19.5"

I use some plywood too and I also cut cedar fence boards to length then slice them and plane them into approx 1/8" strips. Good for smaller projects and I really like working with cedar.

(Have to assume you guys mean AgentJayZ - been following him for years. Highly informative…)

Hi @eflyguy,

You are correct. AgentJayZ. Forgot the Jay part. Thanks. He does great videos.

I wonder how they are coming on that MIGHTY (Canadian) Iroquois engine. They work on it in their spare time.

And what did you do with that? Can’t drop a nice mention of a part and not give details!

Hi @marmak3261 the ballscrew was for converting a manual 12" X 36" lathe to CNC. I bought the ballscrew from a surplus outfit in the Eastern United States. I got a grade C3 & a C0, zero backlash unit for about $300.00 dollars each. They are both new in bag NSK. The lathe works very well. It holds about 0.0009" in Z and about 0.0005 in diameter (X).