I was doing a video in my Medical Device Design course I teach at the medical school in the department of surgery, after the last session people sort of asked why we spent so much time early in the course on CAD and why it mattered (the final project is a shark tank style pitch meeting with real medical VC executives) so I thought a video (the whole course is flipped classroom) on prototyping, and to make the project easier to grasp (and for me to make) the scenario I cooked up was imagining being an engineer at Brembo being asked to design a new brake caliper for a new Ferrari or Porsche. And how you can make both a functional and aesthetic prototype (this uses real axel roller bearings, and has internal LEDs to simulate glowing red-hot brakes like Ferraris at Le Mans. Yes this wheel will actually fit on a Ferrari wheel *(not that the PLA wouldn’t just snap, but you know what I mean). I started with a project someone had done a while back for making a rotor and caliper set and modified from there

Overall this was my comparison image:

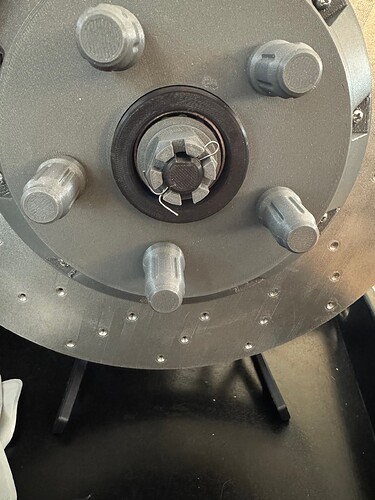

brake lines and bleed ports are hand painted printed in gray V4 on my Form 3

The caliper is held by all 3D printed hardware (the only “real” hardware at the screws holding the hub to the disk and the pads inside the calipers

My buddy complained I had forgotten the cotter pin so made one out of solder (wasn’t sure bending a real cotter pin from my snowblower might not crack the plastic)

Then to add this

added LED light strips to the hub in orange (glows better in the dark)

it’s not perfect but didn’t really have a way for the actual rotor surface to glow easily. The rotor is painted with steel colored acrylic paint, so opaque.

It spins pretty easily.