the good news is that lots of dimensional plastics as well as wood composites use “nominal” dimensions: the actual size is often at the bottom of the tolerance range, or -10% on most plastics…

similar on plywoods…

Even if that was consistently true (which I know for engineering plastics it’s often not), that’s not the really the problem for the most part because you can height of the material.

The problem is it’s supposed to have continuous real-time focusing, so 0.5" focusing within the same part.

Formally, no.

It’s documented in the Python code that’s being written to read and write the file type.

It’s actually pretty simple.

The only part that isn’t super well understood is the header, which contains some device settings that use abbreviations that haven’t been completed deciphered - yet.

I don’t know that the continuous auto-focus is really that feasible.

As @palmercr has documented, the focus step resolution is currently 0.7 mm. It’s likely that this would leave visible witness marks in any engravings when the focus shifted between steps.

I have a similar concern, that I am actively digging into right now, concerning the modulation of the laser’s power: Rather than vary the PWM signal to the power supply, they pulse the supply at full power using a dithering algorithm.

The result is very visible patterns in engravings.

I am working to see if this was done due to a limitation of the power supply, the way the cloud software works, a limitation caused by the PULS files they use, or something I haven’t thought of (probably the most likely).

I wonder if we’ll see some novel definitions here. Perhaps if your machine is the same as Scott’s, “focus on materials” means “to within a defined tolerance of 0.015in” or something like that.

… it looks like continuous auto-focus has been removed from the latest spec sheet. That was also a major differentiator from other machines.

I have a feeling we’re not getting off the Glowforge emotional  for a while.

for a while.

I am happy to be on this ride, but it does have its ups, downs, and loop-de-loops!

Or they raised the head a hair so the top travel of a lens in the current machines is further away (like maybe .5") from the bed ![]()

Mine is actually lower. ![]()

From the top of the crumb tray to the bottom of the head is 1.380".

From the bottom of the head to the plano surface (flat, bottom face) of the lens is 0.535" at full down position.

The lens is 0.080" thick at the edge, so add that in, and you get 1.995" from the crumb tray.

So, if it is all the way to its lowest point (not counting the phase of the stepper, as I manually positioned the lens to its lowest point), it focuses at -0.005".

Push it to the full up position, that places it at +0.465", giving me an effective material range of 0–0.465".

So, as long as they don’t sell 1/2" Proofgrade…

The full 0.5" range of continuous adaptive auto-focus was a major selling point for me. I intend to engrave textured/contoured parts, and without the auto-focus it’s going to prove very difficult.

As for the 0.7mm focus step resolution, I’m hoping it’s stepper motor driven so it can microstep and not just move in full steps.

It is a stepper motor (PM20L-020-HHC3) with a DRV8818 driver.

The driver is capable of full, 1/2, 1/4, and 1/8 steps depending on the setting of two pins.

Unfortunately, the GF is only capable of controlling one of those pins from the head micro-controller (at least on the head I have, v17).

The other pin is tied to ground, which means it can only operate in Full and 1/2 step modes.

Hardware github image says 8825?

Good catch!

For the main steppers (X, Y1, Y2), that is correct.

For the head focus stepper, it is an 8818.

Updating image now…

If you set the focus between 0 and 0.417 the lens moves linearly in 15 steps of 0.0278", after that it does not move any further. Than means it will be .083" out of focus at 0.5". It is a deception to increase the GFUI limit to 0.5" because it doesn’t do anything past 0.417".

If anybody wants to test this on their machine they could engrave a piece of acrylic, focusing at the surface, with a medium LPI such that the lines are touching but not overlapping much. That should leave visible raster lines.

Then raise the acrylic so its top surface is 0.5" above the bed and engrave again with the focus set to 0.5". With nearly 0.1" of defocusing I would expect a visible difference. The lines should less distinct.

Leaving the same set up and repeating the engrave with the focus set to 0.417 should produce a result exactly the same.

Yes I mentioned this some time ago and Dan said they still intended to do it.

It hasn’t been removed. It is still listed on the main Glowforge page.

Is it? I’m not seeing it. There’s a section called “autofocus” but it no longer mentions “continuous” as far as I can see. It does say multipass depths, but that’s different.

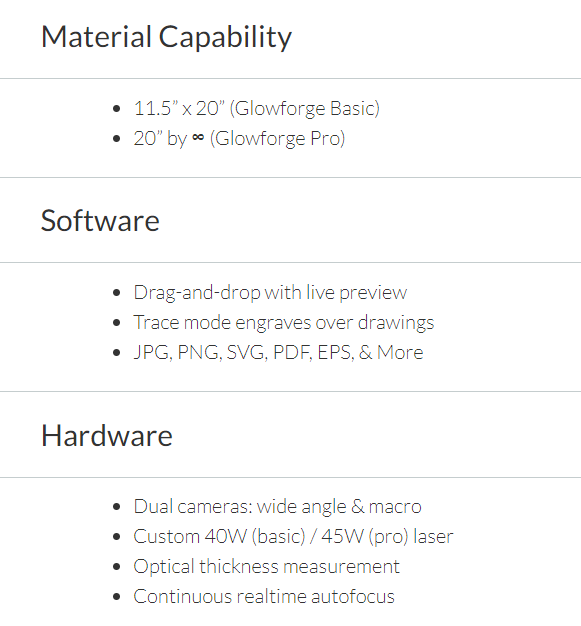

Continuous autofocus has been removed from the specifications sheet

From detailed specifications list:

Revised version from: Glowforge - the 3D laser printer

Autofocus

Completely Internal — Lens moves internally up and down inside the head to focus on materials up to 0.5” (13mm) thick

Exquisitely precise — laser height measurement can measure the surface of the material to within 0.004 inches (0.1mm)

Multipass — Focus can be shifted between engrave passes, allowing detailed depth engraves.

Focus Override — the laser can be defocused to experiment with a range of techniques that require less intense heat

Previously

Autofocus

Completely Internal — Lens moves internally up and down inside the head by 0.5” (13mm)

Continuous Autofocus — Laser focal point can be changed as the head travels, following complex curves during cuts and engraves

Multipass — Focus can be shifted between engrave passes, allowing detailed depth engraves.

Focus Override — the laser can be defocused to experiment with a range of techniques that require less intense heat including acrylic bending and cooking

However, you are correct that it’s still in the front page marketing material…

- 3D Autofocus The lens moves as the laser travels, so you can cut & engrave materials that are curved, uneven, or irregular. Glowforge’s dual cameras measure the thickness of the material to a precision of four one thousandths of an inch.